Content Menu

● Introduction

● 1. Ramseier Koatings Technologies Holdings Ltd.

>> Overview

>> Key Products

● 2. VAAPRO

>> Overview

>> Key Products

● 3. Elcan Industries

>> Overview

>> Key Products

● 4. HK Technologies

>> Overview

>> Key Products

● 5. Russell Finex

>> Overview

>> Key Products

● The Importance of Powder Sieves in Metal Manufacturing

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What is a powder sieve?

>> 2. Why is particle size important in metal powders?

>> 3. How do I choose the right powder sieve for my application?

>> 4. Can powder sieves be customized?

>> 5. What are the benefits of using advanced sieving technology?

Introduction

In the world of manufacturing, the importance of efficient powder sieving cannot be overstated. Powder sieves play a crucial role in ensuring the quality and consistency of metal powders used in various applications, from additive manufacturing to pharmaceuticals. This article explores the top powder sieve manufacturers and suppliers in the metal industry, highlighting their unique offerings and contributions to the field. Among these, Ramseier Koatings Technologies Holdings Ltd. stands out as a leader in providing high-quality powder sieving solutions.

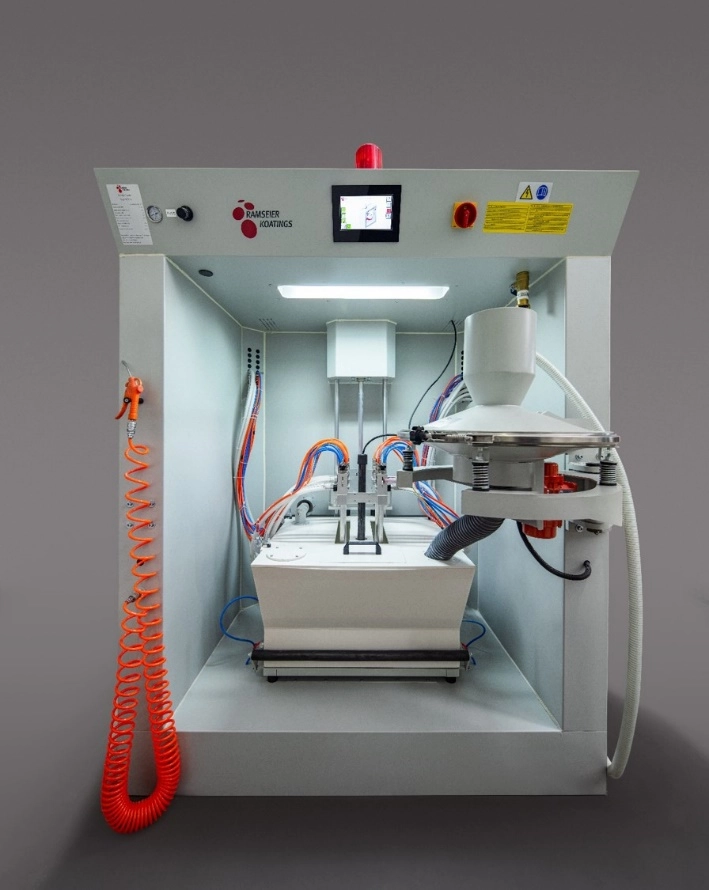

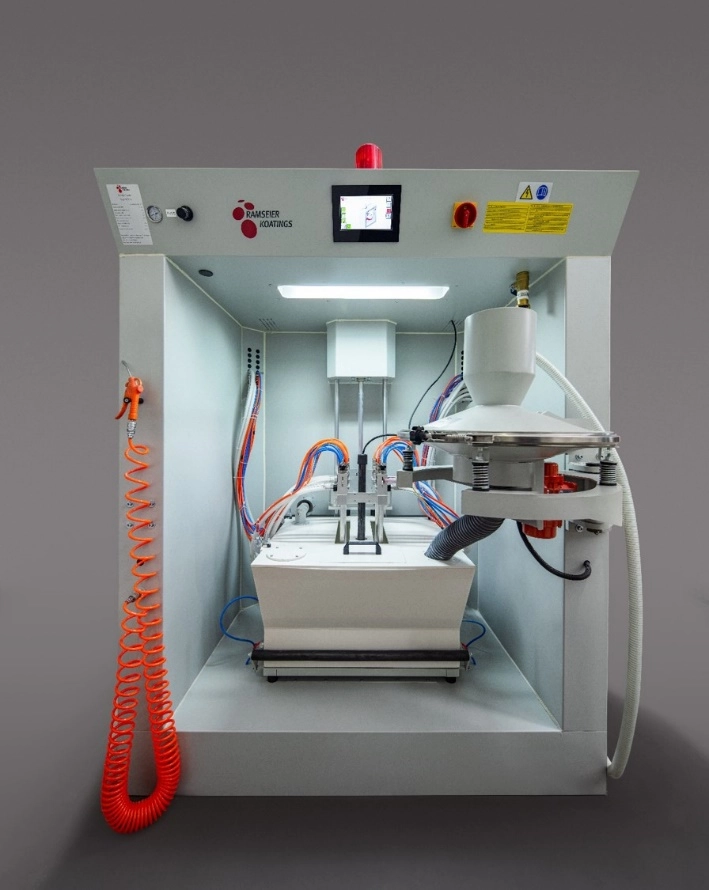

1. Ramseier Koatings Technologies Holdings Ltd.

Overview

Ramseier Koatings Technologies Holdings Ltd. is renowned for its innovative approach to powder sieving technology. The company specializes in manufacturing advanced sieving equipment that meets the stringent demands of the metal industry. Their products are designed to enhance the efficiency of powder processing, ensuring that manufacturers achieve optimal results in their production processes.

Key Products

- High-Efficiency Powder Sieves: These sieves are engineered to provide precise separation of metal powders, ensuring consistent particle size distribution.

- Customizable Solutions: Ramseier offers tailored solutions to meet the specific needs of various industries, including aerospace, automotive, and medical applications.

2. VAAPRO

Overview

VAAPRO is a leading manufacturer of metal powder sieves, known for its high-performance vibro sifters. These sieves are ideal for screening a wide range of metal powders, including aluminum, titanium, and stainless steel.

Key Products

- Vibro Sifters: Designed for efficient powder recovery and quality control in metal 3D printing.

- Customizable Sieving Systems: VAAPRO provides solutions that can be tailored to meet the unique requirements of different manufacturing processes.

3. Elcan Industries

Overview

Elcan Industries specializes in advanced sieving technologies that cater to the needs of the metal powder industry. Their Hi-Sifter technology is particularly notable for its ability to handle ultra-fine powders without the risk of contamination.

Key Products

- Hi-Sifter: A high-energy grading machine that ensures efficient separations and prevents agglomeration of metal powders.

- Sieving Solutions for Additive Manufacturing: Elcan's products are widely used in industries requiring high-performance metal powders for 3D printing and other applications.

4. HK Technologies

Overview

HK Technologies offers a comprehensive range of sieving solutions tailored for the powder metal manufacturing industry. Their products are designed to address the challenges faced by manufacturers in achieving accurate particle size distribution.

Key Products

- Lab & Pilot Sieves: Ideal for small-scale applications and testing.

- Production Sifters: High-capacity screening solutions for large-scale manufacturing processes.

5. Russell Finex

Overview

Russell Finex is a global leader in sieving and filtration equipment, providing innovative solutions for the metal powder industry. Their products are designed to enhance product quality and efficiency in various applications.

Key Products

- Vibratory Separators: Used for grading metal powders into discrete fractions.

- Custom Solutions: Russell Finex offers tailored sieving systems to meet the specific needs of different industries.

The Importance of Powder Sieves in Metal Manufacturing

Powder sieves are essential in the metal manufacturing process for several reasons:

- Quality Control: Ensuring that metal powders meet specific particle size requirements is crucial for maintaining product quality.

- Efficiency: Advanced sieving technologies can significantly enhance the efficiency of powder processing, reducing waste and improving yield.

- Versatility: Powder sieves can be used across various industries, including aerospace, automotive, and pharmaceuticals, making them a valuable asset for manufacturers.

Conclusion

The landscape of powder sieve manufacturing is diverse, with several key players contributing to the advancement of technology in this field. Companies like Ramseier Koatings Technologies Holdings Ltd., VAAPRO, Elcan Industries, HK Technologies, and Russell Finex are at the forefront, providing innovative solutions that enhance the efficiency and quality of metal powder processing. As industries continue to evolve, the demand for high-quality powder sieves will only increase, making these manufacturers essential partners in the production process.

Frequently Asked Questions (FAQs)

1. What is a powder sieve?

A powder sieve is a device used to separate and classify powder materials based on particle size. It is commonly used in various industries, including metal manufacturing, pharmaceuticals, and food processing.

2. Why is particle size important in metal powders?

Particle size affects the flowability, packing density, and sintering performance of metal powders, which are critical factors in manufacturing processes such as additive manufacturing and powder metallurgy.

3. How do I choose the right powder sieve for my application?

When selecting a powder sieve, consider factors such as the type of material being processed, the desired particle size distribution, and the specific requirements of your manufacturing process.

4. Can powder sieves be customized?

Yes, many manufacturers offer customizable powder sieving solutions tailored to meet the unique needs of different industries and applications.

5. What are the benefits of using advanced sieving technology?

Advanced sieving technologies can improve efficiency, reduce contamination risks, and enhance the quality of the final product by ensuring precise particle size control.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.