Content Menu

● Understanding Vibrating Sieves

>> What Are Vibrating Sieves?

>> How Do Vibrating Sieves Work?

● The Importance of Quality in Powder Production

>> Quality Standards in the Industry

>> Consequences of Poor Quality

● Benefits of Using Vibrating Sieves

>> Enhanced Separation Efficiency

>> Versatility in Applications

>> Reduced Downtime and Maintenance

>> Improved Product Quality

>> Cost-Effectiveness

● Applications of Vibrating Sieves in Various Industries

>> Food Industry

>> Pharmaceutical Industry

>> Chemical Industry

>> Recycling and Waste Management

● Choosing the Right Vibrating Sieve

>> Factors to Consider

>> Maintenance Tips

● Conclusion

>> Frequently Asked Questions

In the world of industrial powder production, maintaining quality is paramount. Producers of powders, whether for food, pharmaceuticals, or chemicals, face the constant challenge of ensuring that their products meet stringent quality standards. One of the most effective tools in achieving this goal is the vibrating sieve. This article explores the reasons why industrial powder producers trust vibrating sieves for quality, examining their functionality, benefits, and applications.

Understanding Vibrating Sieves

What Are Vibrating Sieves?

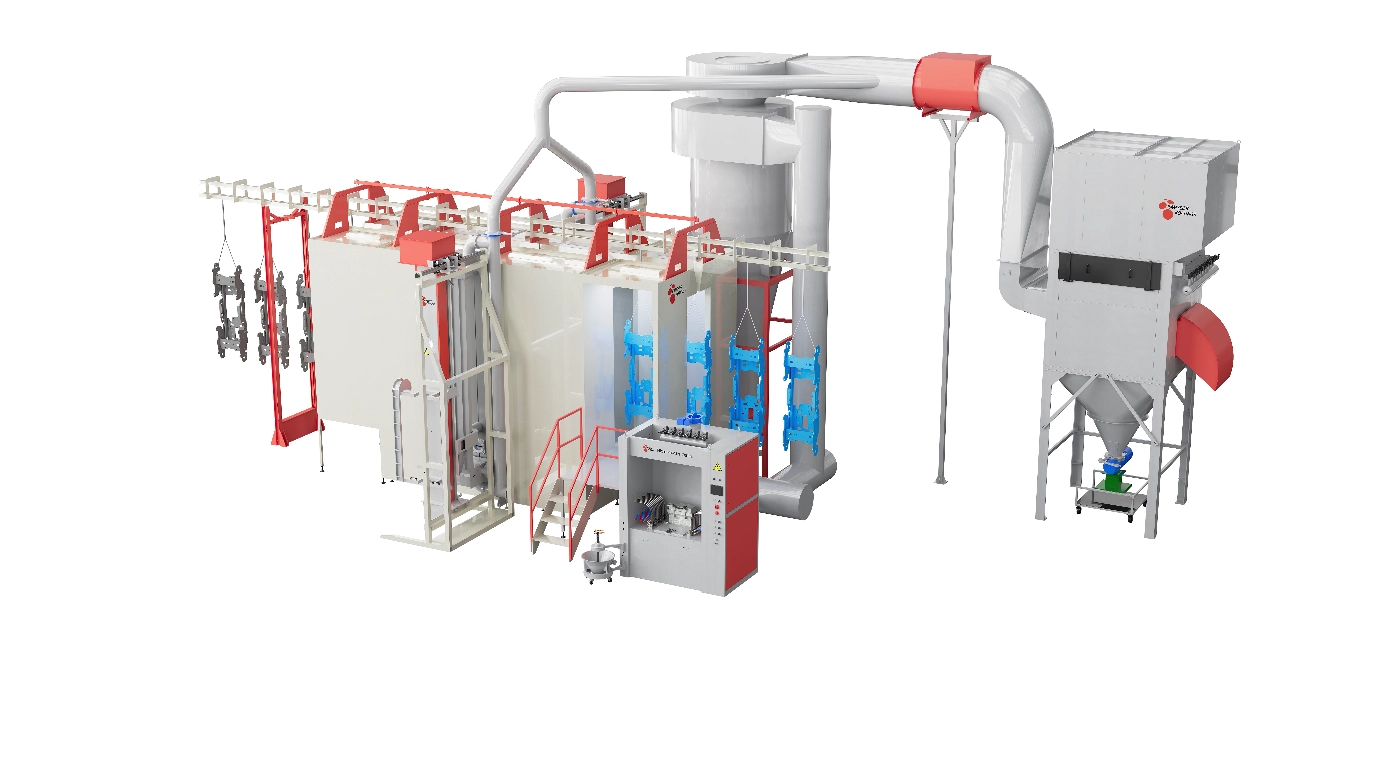

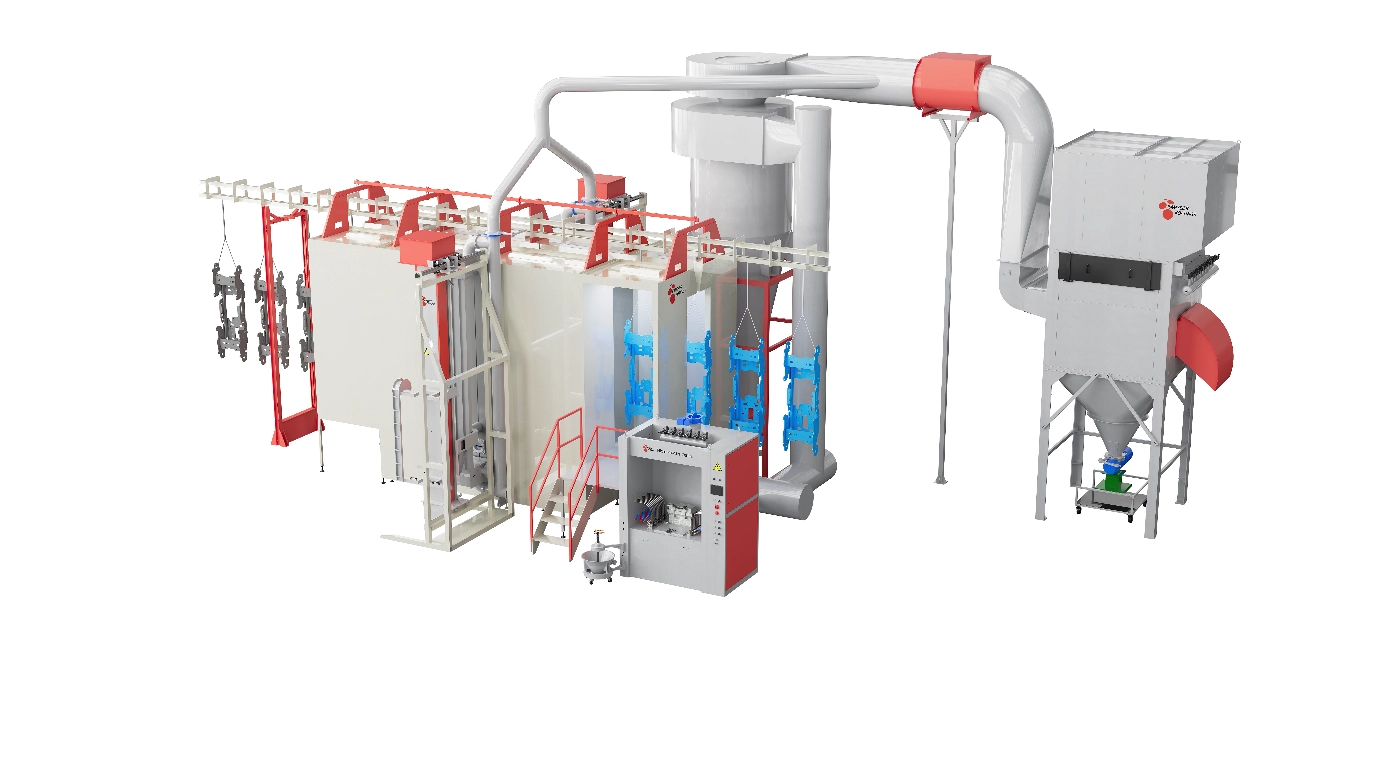

Vibrating sieves are mechanical devices used to separate materials based on size. They utilize a vibrating motion to move particles through a mesh screen, allowing smaller particles to pass through while larger ones are retained. This process is essential in various industries, including food processing, pharmaceuticals, and chemical manufacturing.

How Do Vibrating Sieves Work?

The operation of a vibrating sieve is relatively straightforward. The sieve consists of a screen mesh mounted on a frame, which is connected to a vibrating motor. When the motor is activated, it generates vibrations that cause the material on the screen to move. The design of the sieve allows for adjustable vibration intensity and frequency, enabling producers to optimize the separation process for different materials.

The Importance of Quality in Powder Production

Quality Standards in the Industry

In industries such as food and pharmaceuticals, quality standards are not just guidelines; they are regulatory requirements. Products must be free from contaminants and meet specific particle size distributions to ensure safety and efficacy. For instance, in the pharmaceutical industry, the size of powder particles can significantly affect the dissolution rate and bioavailability of drugs.

Consequences of Poor Quality

Failing to meet quality standards can have severe consequences. In the food industry, contaminated or improperly sized powders can lead to product recalls, legal issues, and damage to brand reputation. In pharmaceuticals, poor quality can result in ineffective medications, posing risks to patient health and safety.

Benefits of Using Vibrating Sieves

Enhanced Separation Efficiency

One of the primary reasons industrial powder producers trust vibrating sieves is their enhanced separation efficiency. The vibrating motion allows for a more thorough and consistent separation of particles, ensuring that only the desired sizes are processed. This efficiency is crucial in maintaining product quality and reducing waste.

Versatility in Applications

Vibrating sieves are highly versatile and can be used for various applications. They can handle different materials, including powders, granules, and even liquids. This adaptability makes them an invaluable tool for producers who work with multiple products or need to switch between different materials frequently.

Reduced Downtime and Maintenance

Another significant advantage of vibrating sieves is their low maintenance requirements. The robust design of these machines minimizes wear and tear, leading to reduced downtime. Producers can rely on vibrating sieves to operate continuously, ensuring a steady production flow and minimizing disruptions.

Improved Product Quality

By effectively removing oversized particles and contaminants, vibrating sieves contribute to improved product quality. This is particularly important in industries where precision is critical. For example, in the food industry, ensuring that powders are free from foreign materials is essential for consumer safety.

Cost-Effectiveness

Investing in vibrating sieves can lead to long-term cost savings for producers. By improving product quality and reducing waste, these machines can enhance overall production efficiency. Additionally, their durability means that producers can expect a good return on investment over time.

Applications of Vibrating Sieves in Various Industries

Food Industry

In the food industry, vibrating sieves are used to ensure that powders, such as flour, sugar, and spices, are free from contaminants and meet specific particle size requirements. This is crucial for maintaining product quality and safety.

Pharmaceutical Industry

Pharmaceutical manufacturers rely on vibrating sieves to ensure that active ingredients and excipients are of the correct size and purity. This is vital for the effectiveness of medications and compliance with regulatory standards.

Chemical Industry

In the chemical industry, vibrating sieves are used to separate and classify powders, ensuring that products meet the necessary specifications for various applications. This includes everything from pigments to fertilizers.

Recycling and Waste Management

Vibrating sieves also play a role in recycling and waste management, helping to separate recyclable materials from waste. This contributes to more efficient recycling processes and reduces the amount of waste sent to landfills.

Choosing the Right Vibrating Sieve

Factors to Consider

When selecting a vibrating sieve, producers should consider several factors, including:

- Material Compatibility: Ensure that the sieve is suitable for the specific materials being processed.

- Screen Size and Mesh Type: Choose the appropriate screen size and mesh type for the desired particle size distribution.

- Vibration Frequency and Amplitude: Adjust these settings to optimize the separation process for different materials.

- Ease of Cleaning: Select a design that allows for easy cleaning to maintain hygiene standards, especially in food and pharmaceutical applications.

Maintenance Tips

To ensure the longevity and efficiency of vibrating sieves, producers should follow these maintenance tips:

- Regularly inspect the sieve for wear and tear.

- Clean the sieve after each use to prevent cross-contamination.

- Monitor vibration levels and adjust settings as needed to maintain optimal performance.

Conclusion

Vibrating sieves are indispensable tools for industrial powder producers, offering enhanced separation efficiency, versatility, and improved product quality. By investing in these machines, producers can ensure that their products meet the highest quality standards, ultimately leading to greater customer satisfaction and business success. As industries continue to evolve, the role of vibrating sieves in maintaining quality will only become more critical.

Frequently Asked Questions

1. What types of materials can vibrating sieves process?

- Vibrating sieves can process a wide range of materials, including powders, granules, and liquids.

2. How do I know which vibrating sieve is right for my application?

- Consider factors such as material compatibility, screen size, and the desired particle size distribution when selecting a sieve.

3. What maintenance is required for vibrating sieves?

- Regular inspections, cleaning after each use, and monitoring vibration levels are essential for maintaining sieve performance.

4. Can vibrating sieves be used in the food industry?

- Yes, vibrating sieves are widely used in the food industry to ensure product safety and quality.

5. What are the benefits of using vibrating sieves over other separation methods?

- Vibrating sieves offer enhanced efficiency, versatility, low maintenance, and improved product quality compared to other methods.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.