Content Menu

● Introduction

● What is Wood Powder Coating Equipment?

>> Understanding Powder Coating on Wood

>> Key Components of Wood Powder Coating Equipment

● Advantages of Using Wood Powder Coating Equipment

>> Superior Durability and Finish Quality

>> Environmental and Energy Benefits

>> Design Flexibility and Aesthetic Appeal

● Applications of Wood Powder Coating Equipment

>> Furniture Manufacturing

>> Architectural Woodwork

>> Specialty Wood Products

● How OEMs Benefit from Wood Powder Coating Equipment

>> Customization and Brand Differentiation

>> Cost Efficiency and Operational Advantages

>> Supporting International Clients

● Key Considerations When Selecting Wood Powder Coating Equipment

>> Powder Type and Compatibility

>> Equipment Flexibility and Automation

>> Technical Support and Training

● Future Trends in Wood Powder Coating Equipment

>> Innovations in Powder Formulations

>> Integration with Smart Manufacturing

>> Expansion into New Markets

● Frequently Asked Questions (FAQs)

Introduction

In the evolving world of surface finishing, wood powder coating equipment has emerged as a revolutionary technology that offers durable, eco-friendly, and aesthetically superior finishes on wood and wood-based products. As a leading Chinese manufacturer, supplier, and OEM service provider of powder coating equipment, we cater to international brands, wholesalers, and producers seeking cutting-edge solutions for wood powder coating applications. This article delves into the technology, benefits, applications, and market opportunities of wood powder coating equipment, providing valuable insights for stakeholders in the powder coating industry.

What is Wood Powder Coating Equipment?

Understanding Powder Coating on Wood

Powder coating is a dry finishing process that uses finely ground particles of pigment and resin, electrostatically charged and sprayed onto a surface, then cured under heat to form a hard, durable finish. Traditionally used on metals, advancements have made powder coating viable for wood substrates such as medium density fiberboard (MDF), hardwood, and other wood-based materials.

Key Components of Wood Powder Coating Equipment

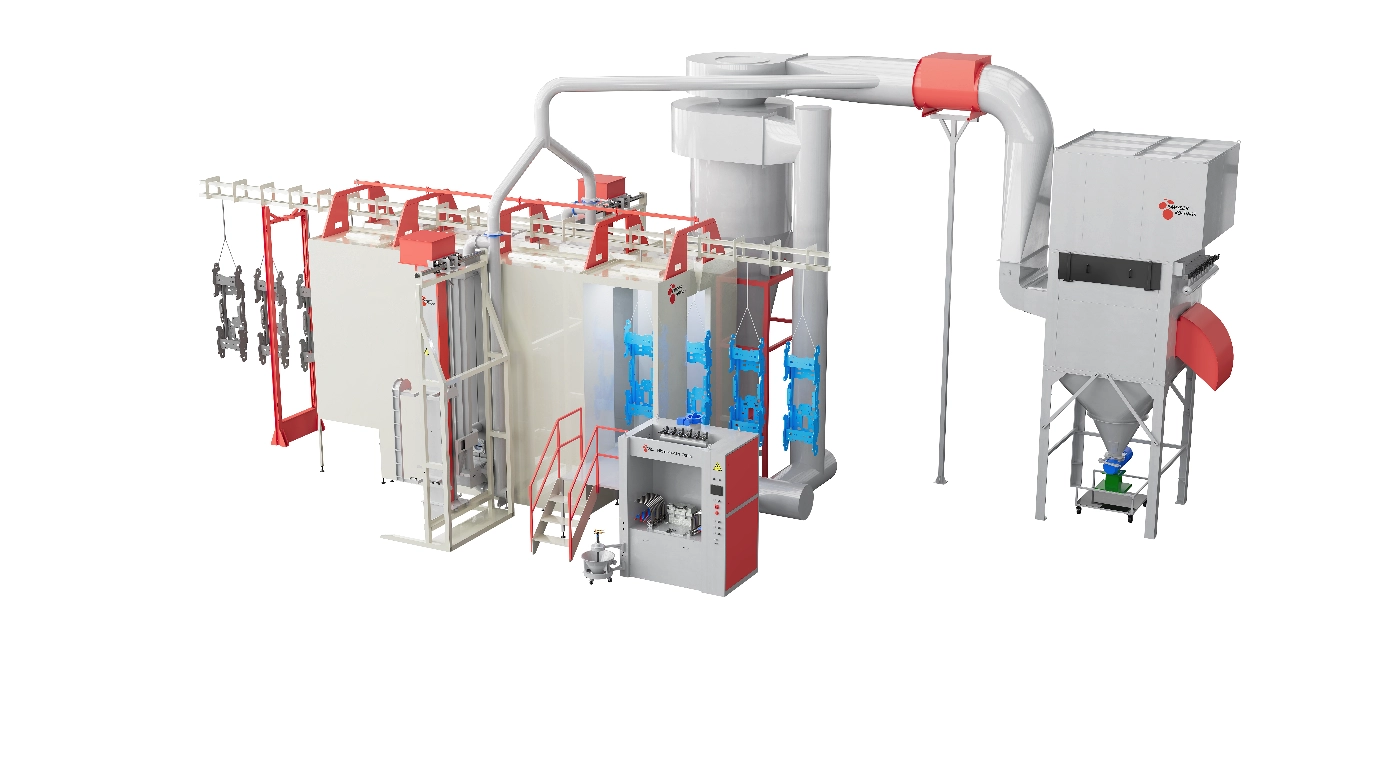

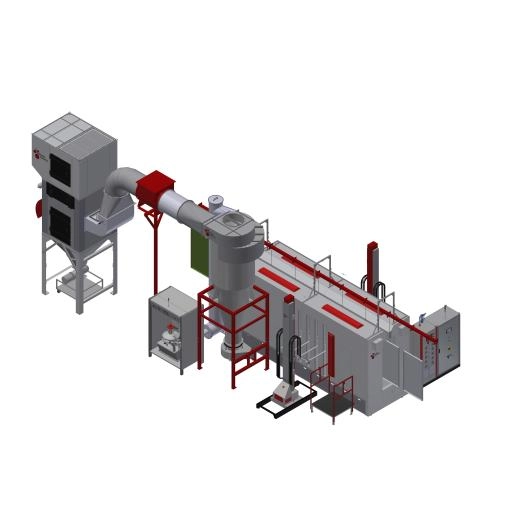

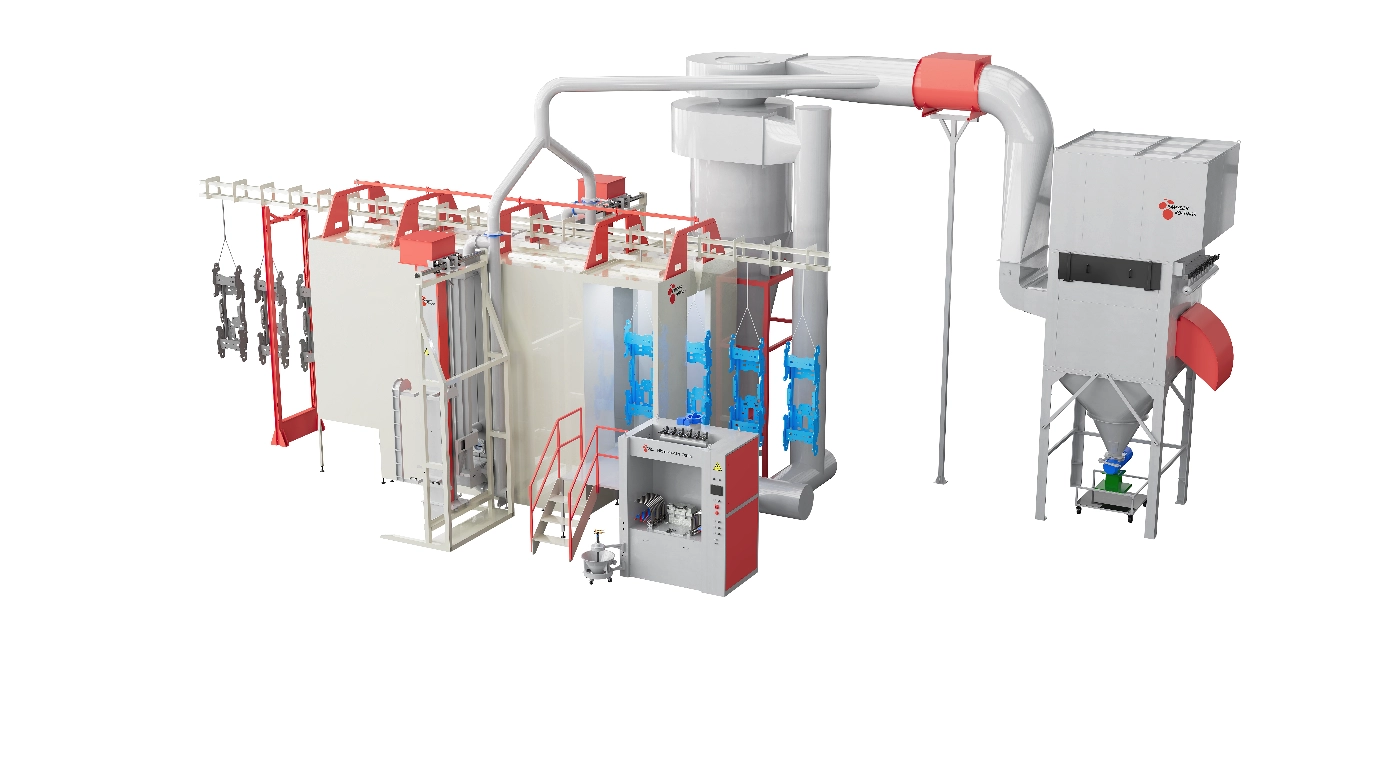

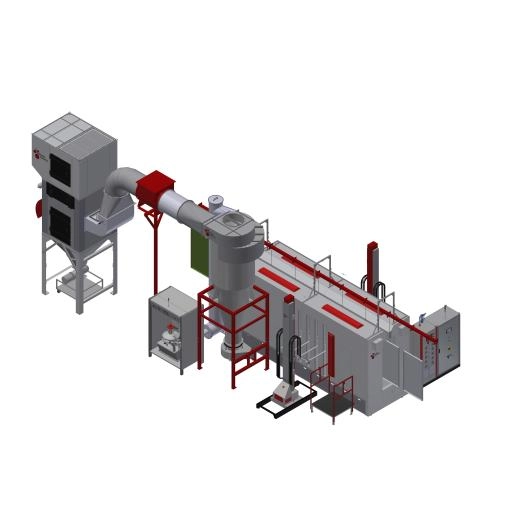

Wood powder coating equipment typically includes:

- Electrostatic spray guns designed for uniform powder application

- Preheating ovens to prepare wood surfaces for coating

- Infrared or convection curing ovens

- Powder recovery systems to reclaim overspray powder for reuse

- Control systems for precise process management

Advantages of Using Wood Powder Coating Equipment

Superior Durability and Finish Quality

Powder coating on wood provides a robust surface that resists scratches, abrasion, and chemical damage, extending the lifespan of furniture and wood products. Unlike traditional liquid coatings, powder coating offers seamless coverage, including edges and contoured surfaces, without the need for multiple coats or sanding between layers.

Environmental and Energy Benefits

Wood powder coating equipment supports energy-efficient processes due to low melting points and short curing times of specially formulated powders. This results in reduced energy consumption and faster production cycles. Additionally, the process is environmentally friendly, producing minimal volatile organic compounds (VOCs) and enabling powder recycling through overspray recovery systems.

Design Flexibility and Aesthetic Appeal

Powder coating allows for a wide range of colors, textures, and effects on wood products. Designers can create complex shapes, rounded edges, and cutouts with seamless coatings that are difficult to achieve with traditional laminates or liquid coatings. This flexibility enhances product appeal and market competitiveness.

Applications of Wood Powder Coating Equipment

Furniture Manufacturing

Office furniture, kitchen and bath cabinets, store fixtures, and ready-to-assemble furniture benefit greatly from powder coating technology. The process accommodates modern design trends such as rounded corners and integrated cable management holes, delivering durable and attractive finishes.

Architectural Woodwork

Doors, window frames, and decorative wood panels coated with powder coatings exhibit enhanced weather resistance and longevity, making them suitable for both interior and exterior applications.

Specialty Wood Products

Barbecue trays, craft wood items, and other specialty products gain from the scratch resistance and seamless finish that wood powder coating equipment provides, improving both functionality and aesthetics.

How OEMs Benefit from Wood Powder Coating Equipment

Customization and Brand Differentiation

OEM manufacturers can leverage wood powder coating equipment to offer bespoke finishes tailored to client specifications. This capability helps brands distinguish their products in competitive markets by providing unique textures, colors, and durable coatings.

Cost Efficiency and Operational Advantages

The one-step finishing process reduces labor and material costs compared to liquid coatings that require multiple coats and drying times. Automated powder coating lines also improve throughput and reduce waste, enhancing profitability for OEMs and suppliers.

Supporting International Clients

As a Chinese OEM supplier, providing advanced wood powder coating equipment and technology to foreign brands and wholesalers enables global partners to access high-quality, cost-effective finishing solutions, strengthening international cooperation and market reach.

Key Considerations When Selecting Wood Powder Coating Equipment

Powder Type and Compatibility

Choosing the right powder formulation—thermal cure or UV-cured—is critical for optimal adhesion and finish quality on wood substrates. UV-curable powders allow lower temperature curing, protecting heat-sensitive wood materials.

Equipment Flexibility and Automation

Manufacturers should consider equipment that supports manual and automatic operation modes, fast color changeover, and efficient powder recovery to meet diverse production needs and sustainability goals.

Technical Support and Training

Reliable OEM partners provide comprehensive technical support, training, and maintenance services to ensure smooth operation and consistent coating quality.

Future Trends in Wood Powder Coating Equipment

Innovations in Powder Formulations

Research continues to develop powders with enhanced properties such as antimicrobial, anti-graffiti, and improved flexibility to meet evolving market demands.

Integration with Smart Manufacturing

The adoption of Industry 4.0 technologies, including IoT-enabled equipment and data analytics, will optimize powder coating processes, reduce downtime, and improve quality control.

Expansion into New Markets

Growing demand for sustainable and durable wood finishes in furniture, construction, and consumer goods sectors is expected to drive the global adoption of wood powder coating equipment.

Frequently Asked Questions (FAQs)

Q1: What types of wood can be powder coated using wood powder coating equipment?

A1: Medium density fiberboard (MDF), hardwood, and other wood-based products can be powder coated effectively with proper equipment and powder formulations.

Q2: How does powder coating on wood differ from traditional liquid coating?

A2: Powder coating provides a seamless, durable finish in a one-step process with less environmental impact and higher efficiency compared to multi-coat liquid systems.

Q3: Can wood powder coating equipment handle complex shapes and edges?

A3: Yes, powder coating can uniformly cover rounded corners, contoured edges, and cutouts, offering design flexibility that liquid coatings and laminates cannot easily achieve.

Q4: What are the energy benefits of using wood powder coating equipment?

A4: The equipment uses powders with low melting points and short curing times, reducing energy consumption and production costs while enabling powder recycling.

Q5: How do OEM manufacturers benefit from partnering with a Chinese wood powder coating equipment supplier?

A5: OEMs gain access to advanced, cost-effective equipment, customized solutions, and strong technical support, facilitating competitive product offerings in global markets.

Come and contact us to shop! ! !

.

.