Content Menu

● Introduction

● What is an Automatic Powder Coating System?

>> Technical Principle

● Key Features of Automatic Powder Coating Systems

>> High Efficiency and Productivity

>> Precision and Consistency

>> Environmental Friendliness

>> Energy Saving

>> Ease of Operation and Maintenance

>> High Stability and Reliability

● Advantages of Automatic Powder Coating Systems

● Applications of Automatic Powder Coating Systems

>> Automotive Industry

>> Electronics and Appliances

>> Furniture Manufacturing

>> Industrial Manufacturing

>> Aerospace Industry

>> Construction and Environmental Equipment

>> Agricultural Machinery

● Future Trends in Automatic Powder Coating Systems

● Frequently Asked Questions (FAQs)

● Conclusion

Introduction

In today's competitive manufacturing landscape, achieving high-quality finishes with maximum efficiency and minimal environmental impact is paramount. As a leading Chinese manufacturer, supplier, and OEM service provider of powder coating systems, we specialize in delivering advanced solutions for overseas brand owners, wholesalers, and producers. This article explores the transformative role of the automatic powder coating system—a cutting-edge technology that revolutionizes surface finishing across multiple industries. We will delve into its technical principles, features, advantages, applications, and future trends, providing a comprehensive understanding of why this system is essential for modern coating operations.

What is an Automatic Powder Coating System?

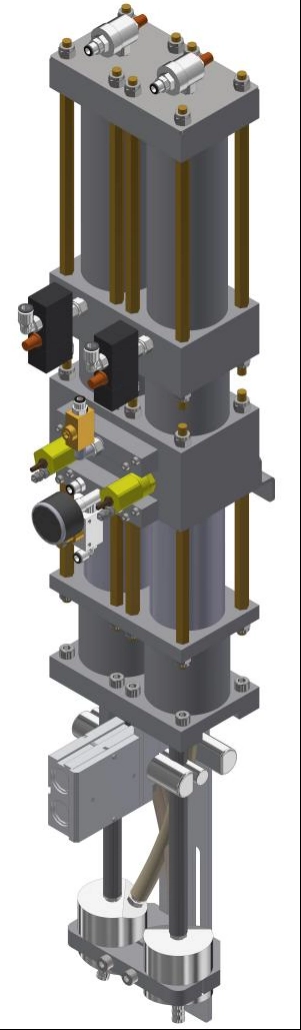

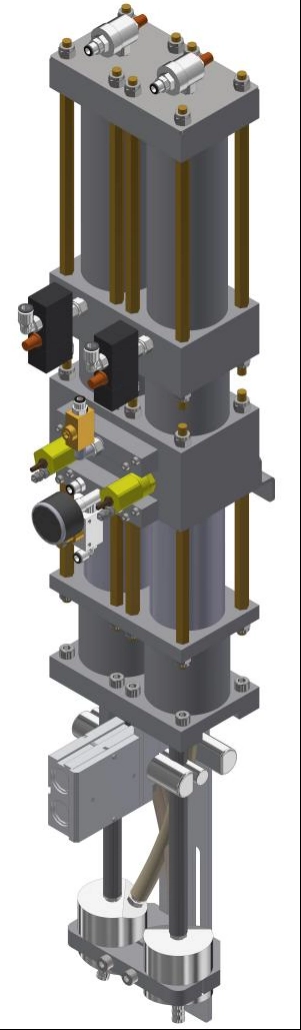

An automatic powder coating system is an integrated production line designed to apply powder coatings onto various substrates using electrostatic principles combined with automation technology. The system typically includes washers, spray booths, powder guns, ovens for drying and curing, and conveyor mechanisms to transport parts through the process seamlessly[3][5].

Technical Principle

The core technology relies on electrostatic adsorption: powder particles are electrically charged and sprayed onto grounded workpieces, ensuring uniform and dense coating coverage. The powder adheres firmly due to the electrostatic charge, then is cured under heat to form a durable, high-quality finish[5].

Key Features of Automatic Powder Coating Systems

High Efficiency and Productivity

Automatic powder coating systems dramatically reduce cycle times by automating the coating process from start to finish. This leads to significantly increased throughput, meeting the demands of mass production environments[5][7].

Precision and Consistency

These systems provide precise control over powder application, ensuring uniform thickness and superior surface finish quality. They can handle complex shapes and diverse materials with consistent results, minimizing defects and rework[5][7].

Environmental Friendliness

Unlike traditional liquid coatings, powder coatings do not use solvents, reducing volatile organic compound (VOC) emissions. The automatic system also minimizes overspray and powder waste through powder recovery units, promoting sustainability[5][7].

Energy Saving

By eliminating paint loss and solvent evaporation, automatic powder coating lines consume less energy during application and curing, contributing to lower operational costs and environmental impact[5].

Ease of Operation and Maintenance

With intelligent management systems, these lines require less manual intervention, simplifying operation and maintenance. Automated controls enable real-time monitoring and adjustments, improving reliability and reducing downtime[5].

High Stability and Reliability

The system maintains stable coating quality and production efficiency, ensuring that manufacturing processes are predictable and reliable, which is critical for brand reputation and customer satisfaction[5].

Advantages of Automatic Powder Coating Systems

- Increased Productivity: Automation accelerates the coating cycle, boosting output without compromising quality[7].

- Improved Quality Control: Consistent powder distribution and curing parameters lead to flawless finishes[7].

- Reduced Waste: Powder recovery systems capture overspray, minimizing material loss and environmental contamination[7].

- Enhanced Safety: Automation limits worker exposure to powders and fumes, creating safer workplaces[7].

- Versatility: Suitable for coating a wide range of substrates, sizes, and shapes across industries[7].

- Data-Driven Optimization: Operational data collection enables continuous process improvements[7].

- Lower Labor Costs: Reduced manual labor requirements translate to cost savings and efficiency gains[7].

Applications of Automatic Powder Coating Systems

The versatility of automatic powder coating systems makes them indispensable in various sectors:

Automotive Industry

Used for coating car bodies, frames, bumpers, wheels, and interior parts, ensuring durable and aesthetically pleasing finishes[5][7].

Electronics and Appliances

Coating enclosures, panels, and chassis of electronic devices and household appliances such as refrigerators and washing machines[5][7].

Furniture Manufacturing

Applying coatings to metal and plastic furniture components for enhanced durability and design appeal[7].

Industrial Manufacturing

Coating machinery parts, tools, pipes, and other industrial components requiring corrosion resistance and wear protection[5][7].

Aerospace Industry

Protecting aircraft components against corrosion and improving surface aesthetics with high-performance coatings[5][7].

Construction and Environmental Equipment

Coating metal doors, windows, railings, and environmental protection equipment like sewage treatment devices[5].

Agricultural Machinery

Applying protective coatings to agricultural tools and machinery, extending service life and performance[5].

Future Trends in Automatic Powder Coating Systems

With ongoing advancements in automation and intelligent technologies, automatic powder coating systems are evolving towards:

- Greater Integration: Seamless connectivity with factory automation and Industry 4.0 platforms.

- Enhanced Data Analytics: Using AI and machine learning to optimize coating parameters and maintenance schedules.

- Sustainability Focus: Development of eco-friendlier powders and energy-efficient curing technologies.

- Customization: Flexible systems capable of handling small batch sizes with rapid changeovers.

These trends will further solidify the automatic powder coating system as a cornerstone of modern manufacturing[5][7].

Frequently Asked Questions (FAQs)

Q1: What materials can be coated using an automatic powder coating system?

A1: These systems can coat metals, plastics, and other substrates with various shapes and sizes, making them highly versatile for multiple industries[5][7].

Q2: How does the automatic powder coating system improve environmental sustainability?

A2: It eliminates solvent use, reduces powder waste through recovery systems, lowers VOC emissions, and consumes less energy compared to traditional coating methods[5][7].

Q3: Can automatic powder coating systems handle complex-shaped parts?

A3: Yes, the electrostatic application and precise control allow uniform coating on complex geometries and hard-to-reach areas[5].

Q4: What are the maintenance requirements for these systems?

A4: Maintenance is simplified due to automation and intelligent monitoring, but regular cleaning of spray booths and powder recovery units is necessary to ensure optimal performance[5].

Q5: How does automation affect labor costs in powder coating?

A5: Automation reduces the need for manual labor, lowering labor costs while increasing throughput and consistency[7].

Conclusion

The automatic powder coating system represents a significant leap forward in coating technology, combining efficiency, precision, environmental responsibility, and cost-effectiveness. Its broad applicability across industries from automotive to aerospace underscores its importance in modern manufacturing. As a trusted Chinese OEM manufacturer and supplier, we are committed to delivering tailored automatic powder coating solutions that meet the evolving needs of global customers, helping them achieve superior product quality and operational excellence.

[1] https://www.nordson.com/en/divisions/industrial-coating-systems/application-solutions/powder-coating/automatic-powder-coating

[2] https://www.wagner-group.com/us/industry/products/powder-coating/complete-systems/

[3] https://powderx.com/automated-powder-coating-systems/

[4] https://www.nordson.com/en/divisions/industrial-coating-systems/application-solutions/powder-coating

[5] https://www.powderspraymachine.com/advantages-of-automatic-powder-coating-production-line/

[6] http://www.sse.com.cn/disclosure/listedinfo/announcement/c/new/2025-04-29/688128_20250429_IZYA.pdf

[7] https://ems-powdercoating.com/automated-powder-coating-system/

[8] https://kjt.ln.gov.cn/kjt/attachDir/2025/01/2025012510161058280.xlsx

[9] http://static.cninfo.com.cn/finalpage/2021-04-06/1209641003.PDF

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.