Content Menu

● Introduction

● Why Powder Sieves Matter

● 1. Ramseier Koatings Technologies Holdings Ltd.

>> Overview

>> Product Offerings

>> Why Choose Ramseier?

● 2. Bloom Engineering

>> Overview

>> Product Offerings

>> Why Choose Bloom Engineering?

● 3. Kason Corporation

>> Overview

>> Product Offerings

>> Why Choose Kason?

● 4. Palamatic Process

>> Overview

>> Product Offerings

>> Why Choose Palamatic Process?

● 5. Farley Greene

>> Overview

>> Product Offerings

>> Why Choose Farley Greene?

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What is a powder sieve?

>> 2. Why is powder sieving important?

>> 3. What industries use powder sieves?

>> 4. How do I choose the right powder sieve?

>> 5. What are the benefits of using ultrasonic sieves?

Introduction

In the rapidly evolving world of powder processing, the demand for high-quality powder sieves has surged, particularly in regions like Qatar. This article explores the top powder sieve manufacturers and suppliers in Qatar, highlighting their offerings and contributions to the industry. Among these, Ramseier Koatings Technologies Holdings Ltd. stands out as a leader in providing innovative powder sieving solutions.

Why Powder Sieves Matter

Powder sieves play a crucial role in various industries, including pharmaceuticals, food processing, and chemical manufacturing. They ensure the uniformity and quality of powders by removing oversized particles and contaminants. This process is essential for maintaining product integrity and compliance with industry standards.

1. Ramseier Koatings Technologies Holdings Ltd.

Overview

Ramseier Koatings Technologies Holdings Ltd. is a prominent player in the powder sieve market, known for its advanced technology and commitment to quality. The company specializes in manufacturing a wide range of powder sieves that cater to various industrial needs.

Product Offerings

- Vibratory Sieves: These are designed for efficient powder separation and are ideal for high-volume applications.

- Ultrasonic Sieves: Utilizing ultrasonic technology, these sieves enhance the efficiency of powder processing by preventing blinding and ensuring consistent flow.

- Custom Solutions: Ramseier offers tailored solutions to meet specific client requirements, ensuring optimal performance in diverse applications.

Why Choose Ramseier?

- Quality Assurance: All products undergo rigorous testing to meet international standards.

- Innovative Technology: Continuous investment in R&D ensures that Ramseier remains at the forefront of powder processing technology.

- Customer Support: A dedicated team provides exceptional after-sales support, ensuring clients maximize the benefits of their products.

2. Bloom Engineering

Overview

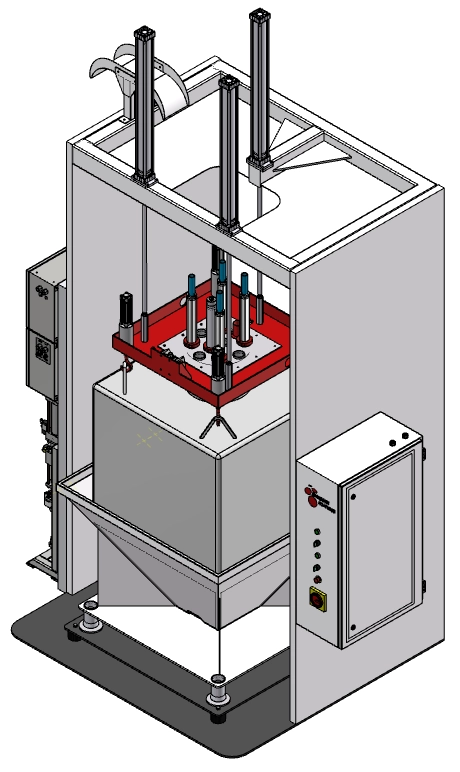

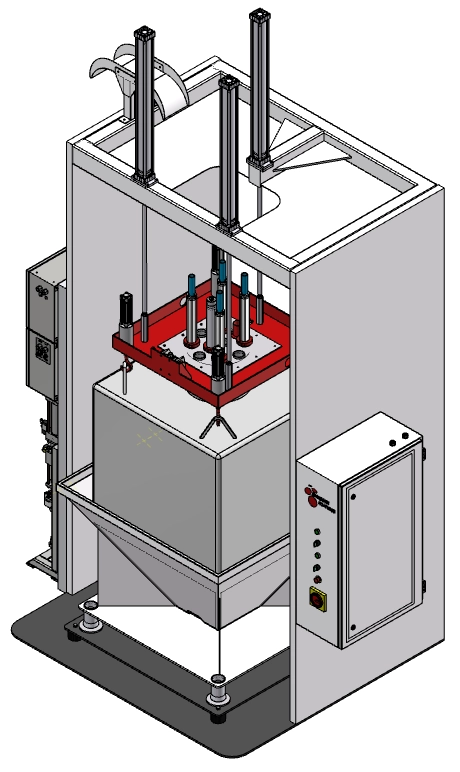

Bloom Engineering is another leading manufacturer of powder sieves in Qatar, known for its robust and reliable products.

Product Offerings

- Vibro Sifter Powder Screeners: These machines are designed for efficient powder separation, ensuring high throughput and minimal downtime.

- Customizable Solutions: Bloom Engineering offers customizable options to cater to specific industry needs.

Why Choose Bloom Engineering?

- Durability: Their products are built to withstand harsh industrial environments.

- Efficiency: High-performance designs ensure optimal powder processing.

3. Kason Corporation

Overview

Kason Corporation specializes in powder processing equipment, including a variety of sieving solutions.

Product Offerings

- Static Scalping Sieves: Ideal for removing oversized particles from dry bulk solids.

- Pneumatic In-Line Centrifugal Sifters: These are designed for high-rate screening in pneumatic conveying systems.

Why Choose Kason?

- Versatility: Their equipment is suitable for a wide range of applications across different industries.

- Compliance: Kason products meet stringent safety and sanitary standards.

4. Palamatic Process

Overview

Palamatic Process is renowned for its comprehensive range of industrial sieves designed for powder processing.

Product Offerings

- Industrial Powder Sieves: These are tailored for various industries, including food, chemical, and pharmaceutical sectors.

- Batch Dryers and Coolers: Complementary equipment for efficient powder processing.

Why Choose Palamatic Process?

- Expertise: Extensive experience in powder handling and processing.

- Innovative Solutions: Continuous development of new technologies to enhance efficiency.

5. Farley Greene

Overview

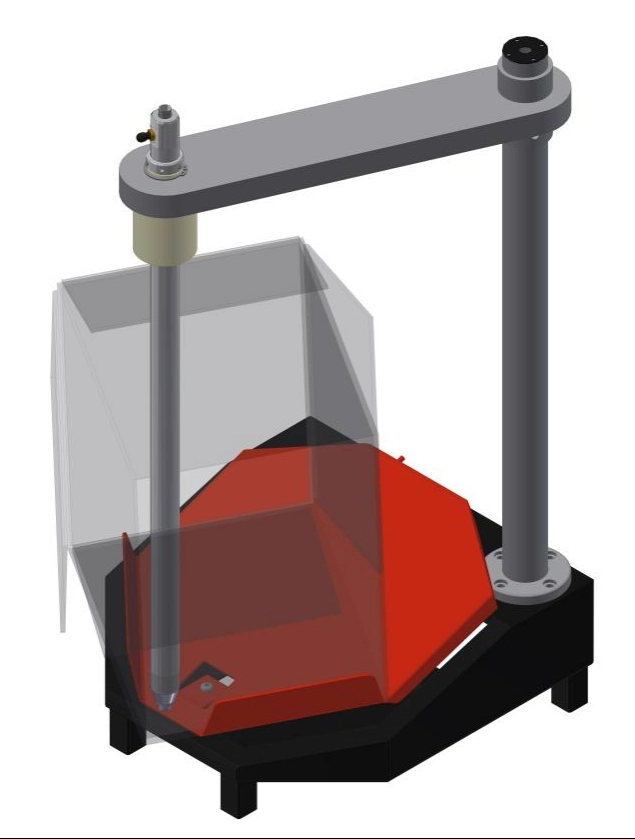

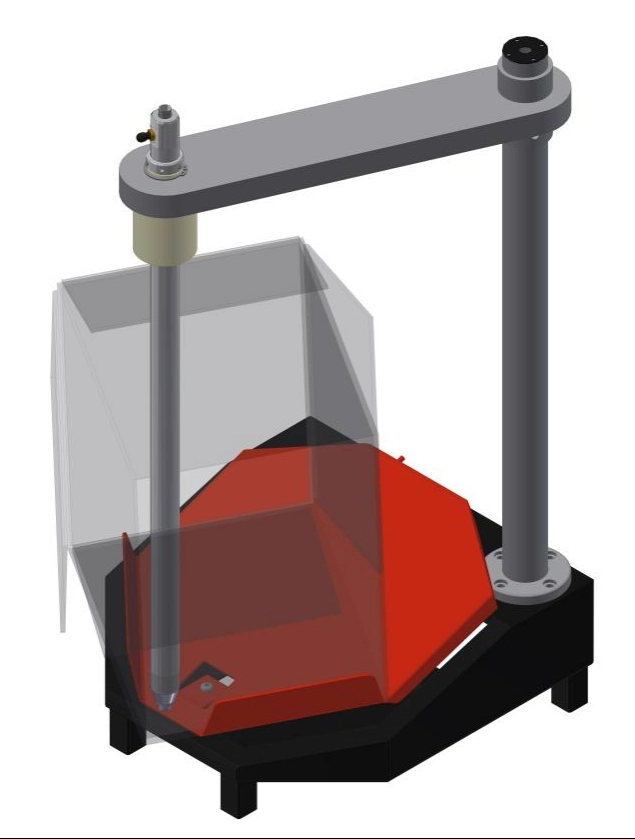

Farley Greene is known for its automated metal powder sieving solutions, catering to the additive manufacturing sector.

Product Offerings

- Sievgen 04-S: An automated ultrasonic sieve designed for recycling and processing metal powders.

- Custom Solutions: Tailored systems to meet specific client needs in powder handling.

Why Choose Farley Greene?

- Automation: Their products reduce manual intervention, increasing efficiency and safety.

- High Throughput: Designed for optimal performance in high-demand environments.

Conclusion

The powder sieve market in Qatar is thriving, with several manufacturers offering innovative solutions to meet the growing demand. Ramseier Koatings Technologies Holdings Ltd. leads the way with its commitment to quality and customer satisfaction. Other notable companies like Bloom Engineering, Kason Corporation, Palamatic Process, and Farley Greene also contribute significantly to the industry, providing a range of products that enhance powder processing efficiency.

Frequently Asked Questions (FAQs)

1. What is a powder sieve?

A powder sieve is a device used to separate particles of different sizes in powder form, ensuring uniformity and quality in various applications.

2. Why is powder sieving important?

Powder sieving is crucial for removing oversized particles and contaminants, which helps maintain product integrity and compliance with industry standards.

3. What industries use powder sieves?

Powder sieves are used in various industries, including pharmaceuticals, food processing, chemicals, and metal additive manufacturing.

4. How do I choose the right powder sieve?

Consider factors such as the type of powder, required throughput, and specific application needs when selecting a powder sieve.

5. What are the benefits of using ultrasonic sieves?

Ultrasonic sieves enhance the efficiency of powder processing by preventing blinding and ensuring consistent flow, making them ideal for challenging materials.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.