Content Menu

● Introduction

● Overview of Powder Sieves

>> Importance of Quality in Powder Sieving

● Leading Powder Sieve Manufacturers in Oman

>> 1. Ramseier Koatings Technologies Holdings Ltd.

>> 2. Western Carbon & Chemical

>> 3. Oman Chemical

>> 4. Nutec Overseas

>> 5. Alif Tools & Hardware Trading

● Features of High-Quality Powder Sieves

>> Material Construction

>> Mesh Size Options

>> Ease of Cleaning

>> Customization

● Applications of Powder Sieves

>> Pharmaceutical Industry

>> Food Processing

>> Chemical Manufacturing

>> Construction

● Conclusion

● Frequently Asked Questions (FAQs)

>> Q1: What is a powder sieve?

>> Q2: Why is quality important in powder sieving?

>> Q3: What industries use powder sieves?

>> Q4: How do I choose the right powder sieve manufacturer?

>> Q5: Can powder sieves be customized?

Introduction

In the realm of industrial processing, powder sieves play a crucial role in ensuring the quality and consistency of powdered materials. This article explores the top powder sieve manufacturers and suppliers in Oman, highlighting their offerings and contributions to various industries. Among these, Ramseier Koatings Technologies Holdings Ltd. stands out as a leading provider of innovative powder sieving solutions.

Overview of Powder Sieves

Powder sieves are essential equipment used in various industries, including pharmaceuticals, food processing, chemicals, and construction. They are designed to separate particles based on size, ensuring that only the desired particle sizes are used in production processes. The efficiency of powder sieves directly impacts product quality, making it vital for manufacturers to choose reliable suppliers.

Importance of Quality in Powder Sieving

Quality control in powder processing is paramount. Poorly sieved powders can lead to inconsistencies in product performance, affecting everything from texture to efficacy. Therefore, selecting a reputable powder sieve manufacturer is crucial for businesses aiming to maintain high standards.

Leading Powder Sieve Manufacturers in Oman

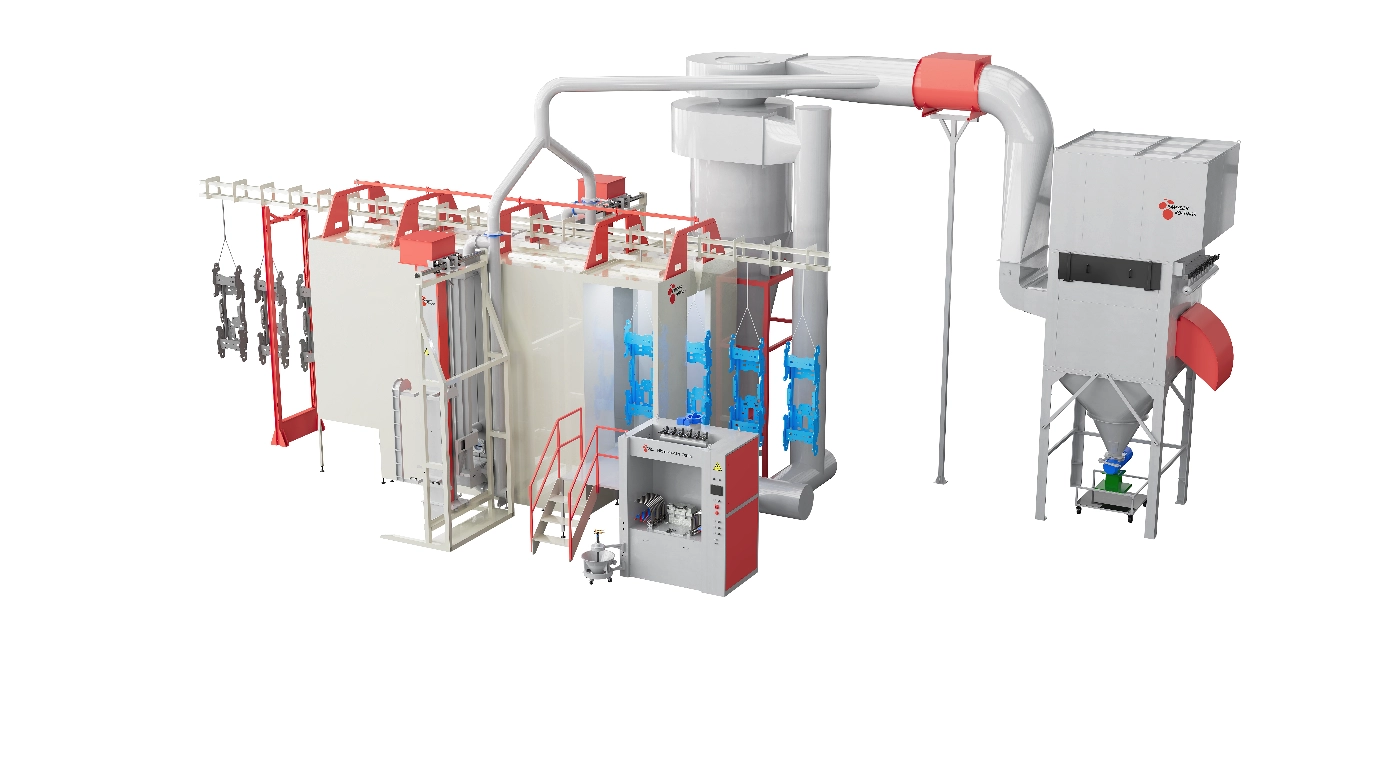

1. Ramseier Koatings Technologies Holdings Ltd.

Ramseier Koatings Technologies Holdings Ltd. is a premier manufacturer of powder sieves in Oman. Known for their advanced technology and commitment to quality, they offer a range of sieving solutions tailored to meet the specific needs of various industries. Their products are designed to enhance efficiency and ensure precise particle size distribution.

2. Western Carbon & Chemical

Western Carbon & Chemical is another key player in the powder sieve market in Oman. They specialize in molecular sieves and offer a variety of powder sieving solutions that cater to the chemical and petrochemical industries. Their commitment to innovation and quality makes them a trusted supplier.

3. Oman Chemical

Oman Chemical is a leading supplier of molecular sieve powders and other chemical products. They provide high-quality powder sieves that are essential for various applications, including drying and purification processes. Their extensive experience in the industry positions them as a reliable partner for businesses in Oman.

4. Nutec Overseas

Nutec Overseas is recognized for its high-performance powder sieves that are widely used in the food and pharmaceutical industries. Their products are designed to meet stringent quality standards, ensuring that customers receive only the best sieving solutions.

5. Alif Tools & Hardware Trading

Alif Tools & Hardware Trading offers a range of industrial equipment, including powder sieves. They are known for their competitive pricing and commitment to customer satisfaction, making them a popular choice among local businesses.

Features of High-Quality Powder Sieves

When selecting a powder sieve, several features should be considered to ensure optimal performance:

Material Construction

High-quality powder sieves are typically made from durable materials such as stainless steel, which resist corrosion and wear. This ensures longevity and reliability in various processing environments.

Mesh Size Options

Different applications require different mesh sizes. A reputable manufacturer will offer a range of mesh sizes to accommodate various powder types and processing needs.

Ease of Cleaning

Powder sieves should be designed for easy cleaning to prevent cross-contamination between batches. Features such as removable screens and smooth surfaces facilitate quick maintenance.

Customization

Many manufacturers offer customization options to meet specific client requirements. This can include modifications to size, mesh type, and additional features such as vibration or air flow systems.

Applications of Powder Sieves

Powder sieves are utilized across various industries, each with unique requirements:

Pharmaceutical Industry

In the pharmaceutical sector, powder sieves are used to ensure the uniformity of active ingredients in medications. This is critical for maintaining dosage accuracy and product efficacy.

Food Processing

Food manufacturers use powder sieves to ensure that ingredients meet safety and quality standards. This includes removing contaminants and ensuring consistent particle sizes for better mixing and processing.

Chemical Manufacturing

In chemical production, powder sieves are essential for separating raw materials and ensuring that only the desired particle sizes are used in formulations. This helps in maintaining product quality and performance.

Construction

In the construction industry, powder sieves are used to process materials such as cement and aggregates. Proper sieving ensures that the materials meet the required specifications for strength and durability.

Conclusion

Choosing the right powder sieve manufacturer is crucial for businesses looking to enhance their production processes. With companies like Ramseier Koatings Technologies Holdings Ltd. leading the way in Oman, businesses can find reliable partners to meet their sieving needs. The importance of quality, customization, and application-specific solutions cannot be overstated in ensuring the success of powder processing operations.

Frequently Asked Questions (FAQs)

Q1: What is a powder sieve?

A powder sieve is a device used to separate particles based on size, ensuring that only the desired particle sizes are used in production processes.

Q2: Why is quality important in powder sieving?

Quality is crucial because poorly sieved powders can lead to inconsistencies in product performance, affecting everything from texture to efficacy.

Q3: What industries use powder sieves?

Powder sieves are used in various industries, including pharmaceuticals, food processing, chemicals, and construction.

Q4: How do I choose the right powder sieve manufacturer?

Consider factors such as material construction, mesh size options, ease of cleaning, and customization capabilities when selecting a manufacturer.

Q5: Can powder sieves be customized?

Yes, many manufacturers offer customization options to meet specific client requirements, including modifications to size and mesh type.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.