Content Menu

● Introduction

● 1. Ramseier Koatings Technologies Holdings Ltd.

>> Overview

>> Product Offerings

>> Market Position

● 2. Kason Corporation

>> Overview

>> Product Offerings

>> Market Trends

● 3. Farleygreene

>> Overview

>> Product Offerings

>> Industry Impact

● 4. Palamatic Process

>> Overview

>> Product Offerings

>> Market Insights

● 5. IAMG

>> Overview

>> Product Offerings

>> Future Prospects

● Market Trends and Insights

>> Growing Demand for Powder Sieves

>> Challenges and Opportunities

● Conclusion

● Frequently Asked Questions

>> 1. What are the main applications of powder sieves?

>> 2. How do ultrasonic sieves enhance powder processing?

>> 3. What factors are driving the growth of the powder sieve market in Hungary?

>> 4. What challenges do powder sieve manufacturers face?

>> 5. How can companies ensure the quality of their powder sieving equipment?

Introduction

In the realm of powder processing, the importance of high-quality sieving equipment cannot be overstated. Powder sieves play a crucial role in ensuring the purity and consistency of powdered materials across various industries, including pharmaceuticals, food processing, and chemical manufacturing. This article explores the top powder sieve manufacturers and suppliers in Hungary, highlighting their offerings, market trends, and the significance of powder sieves in industrial applications.

1. Ramseier Koatings Technologies Holdings Ltd.

Overview

Ramseier Koatings Technologies Holdings Ltd. stands out as a leading manufacturer of powder sieving equipment in Hungary. With a commitment to innovation and quality, they provide a range of advanced sieving solutions tailored to meet the diverse needs of their clients.

Product Offerings

- Ultrasonic Sieves: These sieves utilize ultrasonic technology to enhance the efficiency of powder separation, ensuring high throughput and minimal contamination.

- Vibratory Sieves: Designed for continuous operation, these sieves are ideal for bulk powder processing, offering reliable performance and easy maintenance.

Market Position

Ramseier Koatings has established a strong presence in the Hungarian market, catering to both local and international clients. Their focus on research and development ensures that they remain at the forefront of technological advancements in powder sieving.

2. Kason Corporation

Overview

Kason Corporation is renowned for its extensive range of powder processing equipment, including high-performance sieves designed for various applications.

Product Offerings

- CROSS-FLO Static Scalping Sieves: These economical units are perfect for removing oversized particles from dry bulk solids.

- Batch Dryers and Coolers: Complementing their sieving solutions, Kason also offers equipment for drying and cooling powders, ensuring a comprehensive approach to powder processing.

Market Trends

Kason's commitment to sustainability and energy efficiency aligns with the growing demand for environmentally friendly manufacturing practices in Hungary.

3. Farleygreene

Overview

Farleygreene specializes in automated sieving solutions, particularly for metal powders and other industrial applications.

Product Offerings

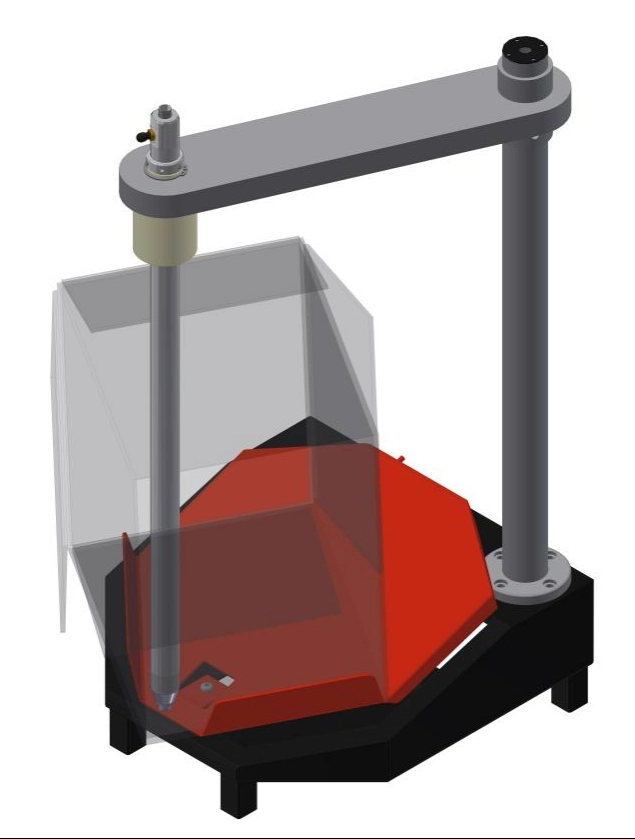

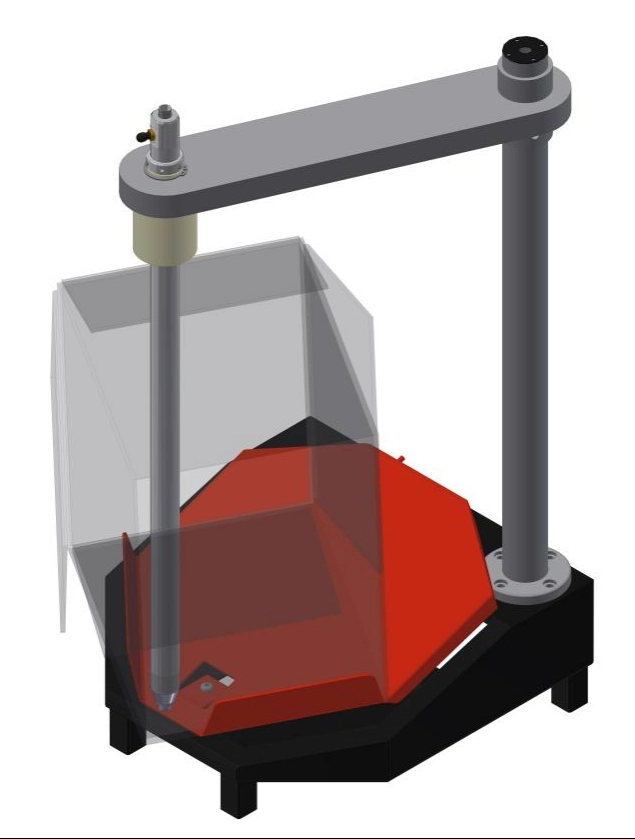

- Sievgen 04-S: This automated metal powder sieving system is designed for high efficiency and minimal operator intervention, making it ideal for modern manufacturing environments.

Industry Impact

Farleygreene's innovative solutions are pivotal in industries such as aerospace and automotive, where precision and quality are paramount.

4. Palamatic Process

Overview

Palamatic Process is a global leader in bulk material handling and powder processing equipment, offering tailored solutions for various industries.

Product Offerings

- Vibratory Sieves: These sieves are designed for high-capacity applications, ensuring effective separation of powders and bulk materials.

- Custom Solutions: Palamatic provides bespoke equipment tailored to specific client needs, enhancing operational efficiency.

Market Insights

With a focus on automation and process optimization, Palamatic is well-positioned to meet the evolving demands of the Hungarian market.

5. IAMG

Overview

IAMG is known for its advanced automated metal powder sieving units, catering to high-tech industries.

Product Offerings

- Automated Sieving Stations: These units are designed for precision and efficiency, making them suitable for additive manufacturing and other high-tech applications.

Future Prospects

IAMG's focus on innovation positions it as a key player in the growing market for advanced powder processing technologies.

Market Trends and Insights

Growing Demand for Powder Sieves

The powder sieve market in Hungary is experiencing significant growth, driven by increasing industrial activities and the need for high-quality powder processing solutions. Key trends include:

- Technological Advancements: The integration of AI and IoT in sieving equipment is enhancing operational efficiency and product quality.

- Sustainability Focus: Manufacturers are increasingly adopting eco-friendly practices, aligning with global sustainability goals.

Challenges and Opportunities

While the market presents numerous opportunities, challenges such as pricing pressures and competition from low-cost imports remain. Companies that invest in innovation and customer-centric solutions are likely to thrive.

Conclusion

The powder sieve industry in Hungary is characterized by a diverse range of manufacturers and suppliers, each contributing to the advancement of powder processing technologies. Companies like Ramseier Koatings Technologies Holdings Ltd., Kason Corporation, and Farleygreene are leading the way, offering innovative solutions that meet the demands of various industries. As the market continues to evolve, staying abreast of technological advancements and market trends will be crucial for success.

Frequently Asked Questions

1. What are the main applications of powder sieves?

Powder sieves are primarily used in industries such as pharmaceuticals, food processing, and chemical manufacturing for ensuring the purity and consistency of powdered materials.

2. How do ultrasonic sieves enhance powder processing?

Ultrasonic sieves utilize high-frequency vibrations to prevent clogging and improve the efficiency of powder separation, resulting in higher throughput and reduced contamination.

3. What factors are driving the growth of the powder sieve market in Hungary?

The growth is driven by increasing industrial activities, technological advancements, and a focus on sustainability in manufacturing processes.

4. What challenges do powder sieve manufacturers face?

Manufacturers face challenges such as pricing pressures from low-cost imports and the need to continuously innovate to meet evolving market demands.

5. How can companies ensure the quality of their powder sieving equipment?

Companies can ensure quality by investing in research and development, utilizing high-quality materials, and adhering to industry standards and certifications.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.