Content Menu

● Understanding Powder Sieves and Mesh Screens

>> What is a Powder Sieve?

>> What is a Mesh Screen?

● Technical Differences Between Powder Sieves and Mesh Screens

>> Construction and Design

>> Operation Mode

>> Particle Size Classification

● Advanced Technologies and Innovations

● Frequently Asked Questions

In numerous industries such as pharmaceuticals, food production, chemical manufacturing, and metallurgy, the processing and classification of powder materials are critical to ensuring product quality and operational efficiency. Two key tools used for this purpose are powder sieves and mesh screens. Although often used interchangeably, these terms refer to equipment with distinct characteristics and applications. This article comprehensively explores their key differences, usage scenarios, technical aspects, and advantages, helping you determine which device best suits your needs.

Understanding Powder Sieves and Mesh Screens

What is a Powder Sieve?

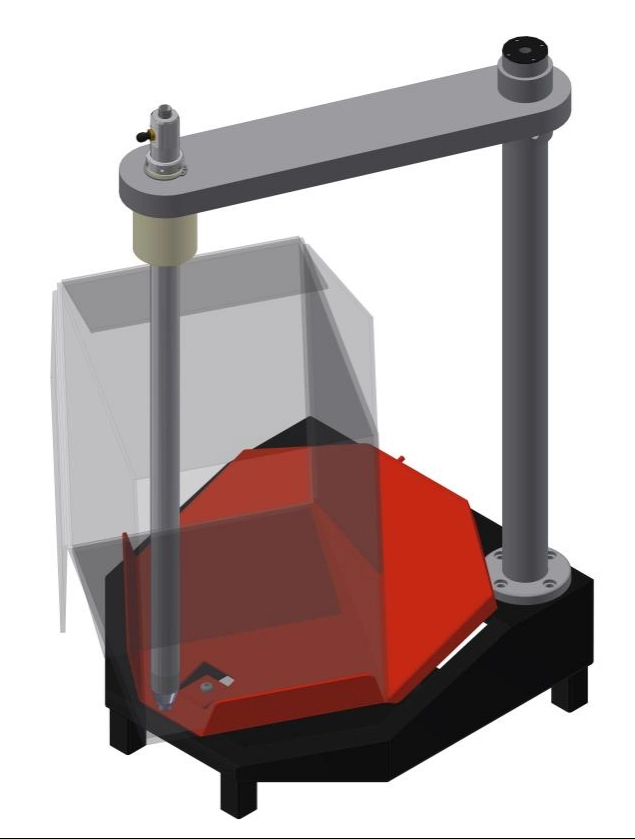

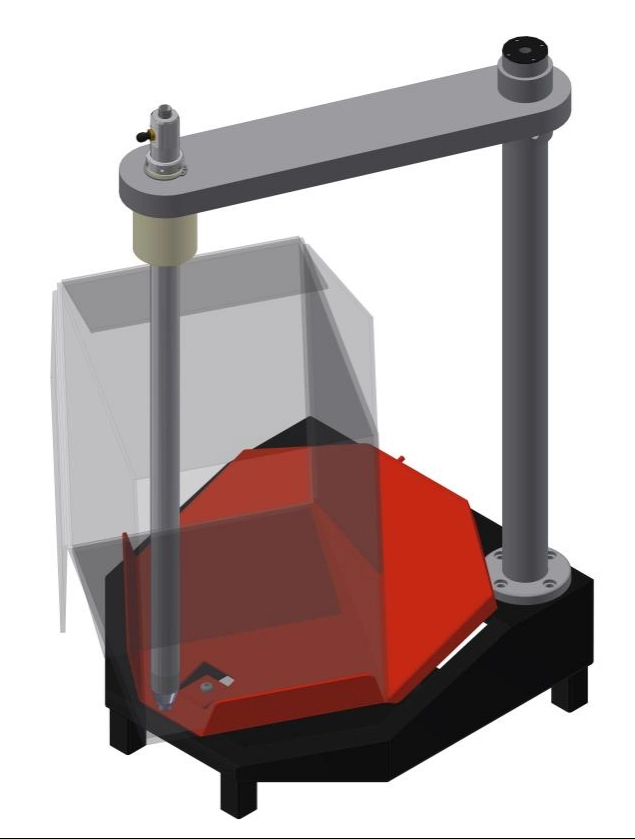

A powder sieve, also known as a sifter, is a device used primarily for separating powder particles by size to ensure consistency and remove contaminants or oversized lumps. It typically consists of a frame holding a fine mesh screen through which the powder passes. Powder sieves can be manual or mechanized, often applying vibration to aid in the passage of fine particles through the mesh while rejecting oversized material.

What is a Mesh Screen?

A mesh screen is a structure composed of woven or welded wire mesh that acts as a filter or barrier to separate materials based on particle size. Mesh screens can be part of larger screening or filtering equipment used for continuous processing rather than batch processing. They are characterized by the mesh opening size (measured in mesh count or microns) and the material of construction, which often determines their durability and application.

Technical Differences Between Powder Sieves and Mesh Screens

Construction and Design

- Powder Sieve: Typically constructed with a rigid frame supporting a fine nylon or stainless steel mesh. Powder sieves use vibration or centrifugal forces to encourage powder flow through the mesh. For example, industrial centrifugal sifters rotate paddles at high RPM to create centrifugal force, forcing fine particles through the nylon mesh while rejecting oversized pieces.

- Mesh Screen: Usually a fixed or tensioned wire mesh mounted within a frame or cage, used for bulk or continuous material separation. Screens may be flat or cylindrical and are commonly integrated into conveying or processing lines. Screens can be constructed of stainless steel or other metals with various mesh sizes adapted to process requirements.

Operation Mode

- Powder Sieve: Operates primarily in batch mode, where a load of powder is screened and classified before moving to the next process step. Vibration or rotation helps prevent mesh clogging and ensures efficient separation of particles.

- Mesh Screen: Often used in continuous flow processes where material continuously passes over or through the mesh. Screens are designed to separate or filter material in-line within production environments.

Particle Size Classification

| Factor | Powder Sieve | Mesh Screen |

| Processing Type | Batch processing | Continuous flow |

| Particle Size Range | Ultra-fine to medium (0.02 mm–2 mm) | Coarse to medium (>44 microns typical) |

| Operation Mode | Vibration or centrifugal motion | Fixed or vibrating during flow |

| Applications | Food, pharma, chemical, additive manufacturing powders | Agriculture, bulk industrial processing, filtration |

| Maintenance | Requires frequent cleaning and mesh replacement | Designed for longer service intervals |

| Mesh Material | Nylon or stainless steel | Mostly stainless steel |

For high-precision powder classification, batch sieving provides better control and flexibility. For large-scale, continuous bulk processing, mesh screens are more efficient and practical.

Advanced Technologies and Innovations

Recent innovations have improved both powder sieving and mesh screening technologies:

- Ultrasonic Deblinding: Using ultrasonic vibrations to prevent or clear mesh blinding, especially beneficial for fine powders or sticky materials.

- Modular Screen Grids: Dividing large screen areas into smaller units with dedicated cleaning components, improving efficiency and ease of maintenance[2].

- Automated and Integrated Systems: Integration with industrial IoT for real-time monitoring and automated cleaning functions to reduce downtime.

Frequently Asked Questions

1. Can powder sieves and mesh screens be used interchangeably?

While both separate particles by size, powder sieves are typically used for batch processes and are better for fine powders; mesh screens are more suited for continuous processing and coarser materials.

2. How is mesh size measured, and what does it mean?

Mesh size refers to the number of openings per inch of screen or the size of openings in microns. Larger mesh numbers correspond to finer openings and smaller particles passing through.

3. What causes mesh blinding, and how can it be prevented?

Mesh blinding occurs when powder particles clog mesh openings, impeding material flow. Prevention includes vibrating the mesh, ultrasonic cleaning, or using coated meshes that reduce particle adhesion.

4. How do centrifugal sifters differ from vibratory sieves?

Centrifugal sifters spin paddles to create centrifugal force pushing powder through the mesh, ideal for fine powders; vibratory sieves use vibration to shake powder through openings, suitable for a range of particle sizes.

5. What materials are powder sieves and mesh screens made of?

Common materials include stainless steel for durability and nylon for sensitive applications such as pharmaceuticals and food, to avoid metal contamination.

[1] https://www.palamaticprocess.com/differences-between-vibrating-sieve-and-a-centrifugal-sieve

[2] https://patents.google.com/patent/WO2020216351A1/zh

[3] https://www.russellfinex.com/en/news-and-events/sieving-powders/

[4] https://www.linguee.com/english-chinese/translation/mesh+screen.html

[5] https://www.espimetals.com/index.php/faq/327-technical-data/stainless-steel/334-understanding-mesh-sizes

[6] https://max.book118.com/html/2017/0611/113858366.shtm

[7] https://sanyuantangcn.com/blog/different-types-of-sieves.html

[8] https://patents.google.com/patent/CN103167914A/zh

[9] https://www.goughengineering.com/en/articles/what-is-the-difference-between-a-sieve-and-a-screen

[10] https://patents.google.com/patent/CN103476514B/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.