Content Menu

● Overview of Powder Sieving in the Coating Industry

>> What is Powder Sieving and Why It Matters

>> Challenges Faced in Conventional Sieving

● Recent Advances in Powder Sieve Technology

>> Ultrasonic Sieving: Enhancing Efficiency and Quality

>>> Working Principle

>>> Benefits in Powder Coating

>> Mechanical Innovations: Compact and Modular Sieving Equipment

>> Multi-Stage and Cascade Sieving Systems

● Integration of Sieve Technology with Emerging Industry Trends

>> Support for Nanotechnology-Enhanced Coatings

>> Enabling Low-Temperature and Smart Coatings

>> Energy Efficiency and Sustainability

● Future Directions and Innovations

>> Digitalization and Automation

>> Customizable Sieving Solutions

>> Research Around Liquid-Assisted Sieving

● Conclusion

>> Related Questions and Answers

Powder sieve technology is an essential part of the powder coating industry, playing a critical role in ensuring the quality, consistency, and performance of powder coatings. With evolving market demands, rising raw material costs, and growing sustainability concerns, the technology surrounding sieving and screening powders in coating processes has witnessed significant innovation. This article explores contemporary trends in powder sieve technology, covering equipment advancements, process optimization, and integration with cutting-edge coating innovations. It also elucidates how these advancements are shaping the future of the powder coating industry globally.

Overview of Powder Sieving in the Coating Industry

What is Powder Sieving and Why It Matters

Powder sieving is the process of separating particles of powder coating material by size using a mesh or screen. This is crucial because powder coatings require a uniform particle size to produce a consistent film with desirable properties like toughness, adhesion, and visual smoothness. Any contamination or oversize particles can result in defects such as poor coverage, uneven coating thickness, or surface irregularities.

The powder coating process involves creating a plastic mix of resin, pigments, and additives. After mixing and cooling, the material is crushed and micronized before classification and final sieving. The sieve ensures that only powders within the desired size range reach the coating application line. Thus, powder sieving is fundamental for product quality control and maintaining superior finishes.

Challenges Faced in Conventional Sieving

Traditional sieving methods face several challenges in the powder coating sector:

- Static Charge Build-up: Because powder coatings are electrostatically charged for application, static electricity can accumulate on sieve meshes, causing blinding or blockage. This reduces sieve efficiency and throughput.

- Mesh Deformation: Continuous use can alter the mesh aperture sizes, allowing oversized particles to pass through or blocking material flow.

- Laborious Cleaning and Maintenance: Spring-mounted and other conventional sieves are difficult to dismantle, leading to increased downtime during cleanings, especially as batch sizes shrink requiring frequent product changeovers.

- Quality Control Issues: Off-line or intermittent screening may compromise product consistency.

These challenges have spurred innovation towards more efficient, reliable, and easy-to-maintain sieving technologies in powder coatings.

Recent Advances in Powder Sieve Technology

Ultrasonic Sieving: Enhancing Efficiency and Quality

One of the most significant trends is the adoption of ultrasonic sieving technology in the powder coating industry. Ultrasonic sieving uses high-frequency vibrations to improve powder separation by preventing particle agglomeration and reducing static-induced mesh blinding.

Working Principle

Ultrasonic sieves integrate ultrasonic transducers that generate vibrations transmitted through the mesh. These vibrations help powders flow more freely, keeping apertures clear and facilitating passage of particles that meet size criteria.

Benefits in Powder Coating

- Reduced Mesh Blinding: Static buildup and particle clumping, which block mesh openings, are minimized.

- Improved Sieving Capacity: Higher throughput without sacrificing quality.

- Enhanced Product Consistency: Uniform particle size distribution leads to better coating films.

- Reduced Downtime: Easier cleaning and less frequent maintenance.

Many leading powder coating manufacturers have integrated ultrasonic sieving to maintain competitive edge and optimize production efficiency.

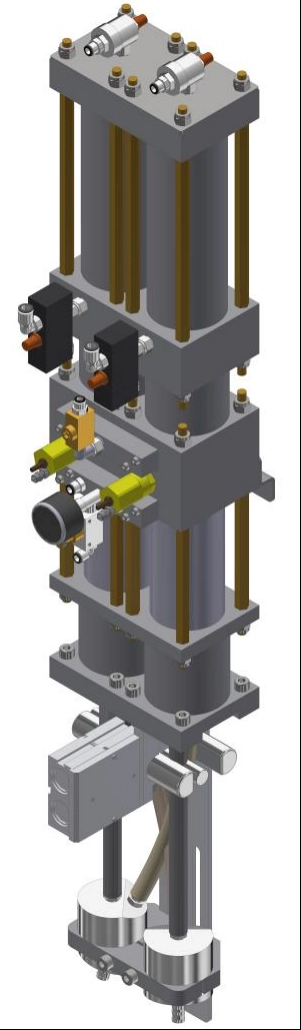

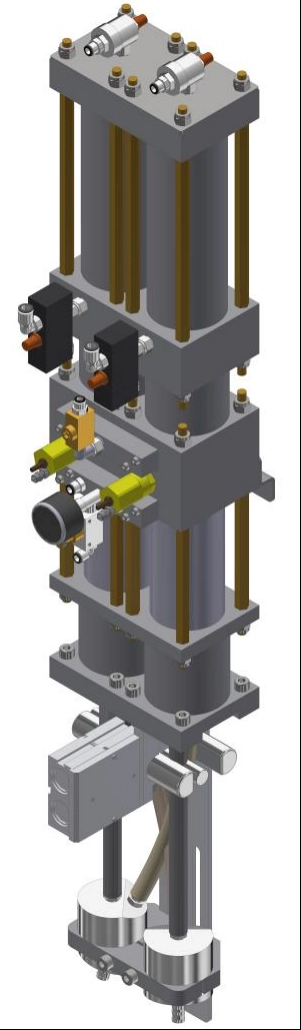

Mechanical Innovations: Compact and Modular Sieving Equipment

To address cleaning and maintenance challenges, there is a clear move towards compact, modular sieve designs that facilitate quick disassembly and thorough cleaning. These innovations include:

- Tool-less or quick-release screen mounting.

- Smaller footprint designs suitable for limited production space.

- Enhanced sealing to prevent contamination and dust leakage.

These design improvements reduce downtime during product changes and cleaning, especially important as manufacturers adopt more frequent product variations.

Multi-Stage and Cascade Sieving Systems

Advanced coating powder production increasingly uses multi-stage or cascade sieving systems that combine different sieve methods or mesh sizes in series. This approach achieves:

- Greater precision in particle size distribution.

- Removal of fines, oversize particles, and contaminants at different stages.

- Optimization of powder flow properties by conditioning material progressively.

Cascade systems are frequently integrated with upstream micronization and post-classification units to deliver highly consistent powders.

Integration of Sieve Technology with Emerging Industry Trends

Support for Nanotechnology-Enhanced Coatings

Nanotechnology is revolutionizing powder coatings by incorporating nanoparticles such as silica or titanium dioxide to gain self-cleaning, antimicrobial, or enhanced durability features. Such formulations require precise particle size control for functional performance, making advanced sieving technologies critical for their manufacture.

Ultrasonic and multi-stage sieves enable safe and effective handling of delicate nanoparticle-infused powders by preventing agglomeration and ensuring uniform dispersion before application.

Enabling Low-Temperature and Smart Coatings

New powder coating products often demand:

- Low-temperature curing ability for heat-sensitive substrates.

- Smart coatings with self-healing, thermochromic, or anti-static functionalities.

The unique powder compositions for these coatings necessitate refined sieving for consistent quality. Modern sieve technologies handle these evolving materials with ease, contributing to broader application fields from automotive interiors to electronics.

Energy Efficiency and Sustainability

Sustainability goals are pushing for lower energy use in coating processes. Efficient powder sieving reduces waste by eliminating contaminants and off-size particles early, thereby improving yield and reducing scrap. Technologies like ultrasonic sieving contribute to lower operational energy consumption by enhancing throughput and reducing need for reprocessing.

Future Directions and Innovations

Digitalization and Automation

Industry 4.0 principles are making their way into sieve technology through:

- Automated monitoring of sieve performance using sensors.

- Real-time data analytics to predict and prevent mesh blockage.

- Integration with digital control systems for adaptive screening.

These systems provide continuous quality assurance and minimize human intervention, boosting productivity.

Customizable Sieving Solutions

Manufacturers seek sieving equipment tailored to specific powder formulations and production scales. Modular designs combined with flexible operational parameters enable personalized sieving configurations, meeting diverse industry needs from small batch production to large-scale continuous manufacturing.

Research Around Liquid-Assisted Sieving

Experimental advances include using liquid additives in powder extrusion and coating processes to improve powder flow and particle morphology. Such methods may influence future sieve technology development by modifying powder properties upstream.

Conclusion

Powder sieve technology in the coating industry is evolving rapidly to meet the demands of higher quality, efficiency, and new functional coating formulations. Ultrasonic sieving stands out as a transformative approach to handling electrostatically charged powders, complemented by innovations in equipment design, multi-stage screening, and integration with nanotechnology and smart coatings. The trend towards automation and sustainability will further define sieve technology's role as a cornerstone of powder coating production.

Related Questions and Answers

Q1: Why is ultrasonic sieving preferred over traditional sieving in powder coating?

A1: Ultrasonic sieving reduces mesh blinding caused by static charge, improves powder flow, increases throughput, and enhances product consistency compared to traditional vibration-only sieves.

Q2: How does powder particle size affect coating quality?

A2: Uniform particle size ensures smooth, even coatings with good adhesion and durability. Oversized or agglomerated particles cause defects like rough surfaces or weak bonding.

Q3: What challenges do static charges pose in powder sieving?

A3: Static charges cause powder particles to stick to the sieve mesh, blocking apertures and reducing sieving efficiency, leading to inconsistent powder quality.

Q4: How do multi-stage sieving systems benefit powder coating production?

A4: They allow precise separation and removal of contaminants and particle size fractions in stages, improving powder uniformity and coating performance.

Q5: What role does sieve technology play in supporting nanotechnology in coatings?

A5: Advanced sieving ensures even distribution and proper handling of nanoparticle-containing powders, which is critical for achieving enhanced functional properties in nanocoatings.

[1] https://www.chinapowdercoating.com/emerging-technologies-shaping-the-future-of-powder-coatings/

[2] https://patents.google.com/patent/CN101802055B/zh

[3] https://www.powderbulksolids.com/screening-separation/ultrasonic-sieving-in-the-powder-coating-industry

[4] https://patents.google.com/patent/CN102355941A/zh

[5] https://www.russellfinex.com/en/case-studies/powder-coating-sieving-technology/

[6] https://patents.google.com/patent/WO2020216351A1/zh

[7] https://www.ulprospector.com/knowledge/18349/pc-latest-trends-in-powder-coating-technology/

[8] https://patents.google.com/patent/CN1628155A/zh

[9] https://www.ramseierkoatings.com/news/Powder-Sieving-Techniques-for-Consistent-Coating-Results.html

[10] https://patentimages.storage.googleapis.com/d7/07/4a/5ff19fc851355c/CN117280001A.pdf

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.