Content Menu

● Introduction

● What Are Powder Sieve Systems?

>> Understanding Powder Sieve Systems

>> Key Components and Types

● Why Choose Professional Powder Sieve System Suppliers?

>> Expertise and Customization

>> Advanced Technology Integration

>> Quality Assurance and Compliance

● Applications of Powder Sieve Systems

>> Chemical and Pharmaceutical Industries

>> Additive Manufacturing

>> Food and Metallurgy

● Advantages of Partnering with a Chinese Powder Sieve System Manufacturer

>> Cost-Effectiveness

>> Advanced Manufacturing Capabilities

>> Extensive Product Range

>> Global Reach and Experience

● How to Choose the Right Powder Sieve System Supplier?

>> Evaluate Technical Expertise

>> Assess Technology and Innovation

>> Consider After-Sales Support

>> Verify Quality Certifications

>> Review Customer Feedback and Case Studies

● Future Trends in Powder Sieving Technology

>> Automation and Connectivity

>> Enhanced Screening Efficiency

>> Sustainability Focus

● Frequently Asked Questions (FAQs)

● Conclusion

Introduction

In the global powder processing industry, precision and efficiency in particle separation are paramount. As a leading Chinese manufacturer specializing in powder sieve systems, we provide OEM services to international brands, wholesalers, and producers. This article explores the critical role of powder sieve system suppliers, the latest technologies, and how partnering with a reliable supplier can optimize your production process.

What Are Powder Sieve Systems?

Understanding Powder Sieve Systems

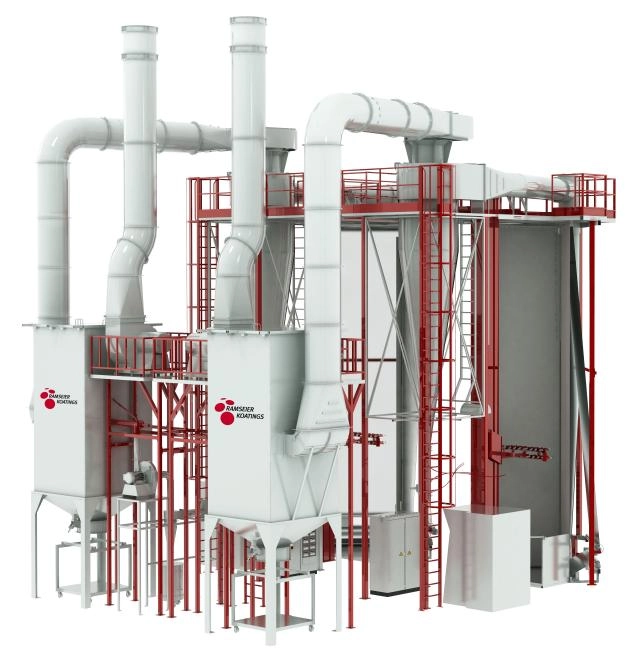

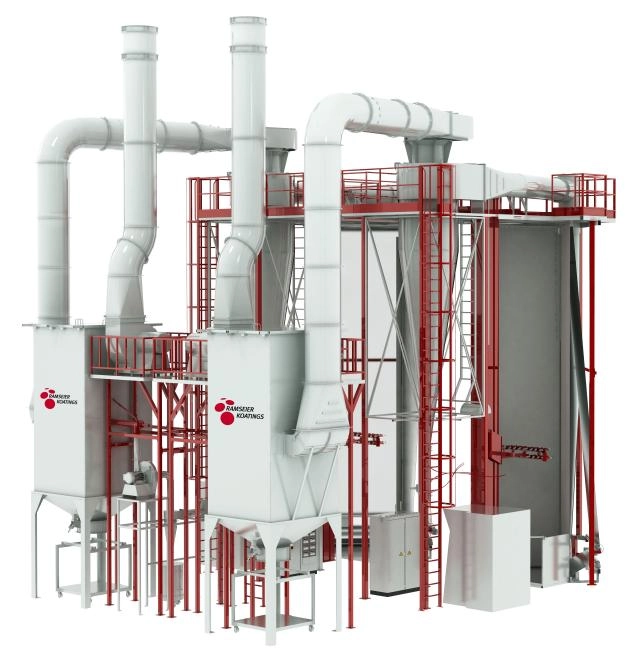

Powder sieve systems are industrial machines designed to separate powders based on particle size, ensuring uniformity and quality in the final product. These systems are essential in industries such as chemicals, pharmaceuticals, metallurgy, food processing, and additive manufacturing, where precise particle size distribution is crucial[1][2].

Key Components and Types

- Vibratory Sieves: Use vibration to pass powders through mesh screens, suitable for fine powders.

- Ultrasonic Sieves: Employ ultrasonic waves to prevent mesh blinding and improve screening efficiency.

- Tumbler Screening Machines: Provide gentle, high-precision screening for delicate materials.

- Airflow Sieves: Utilize air streams for screening ultra-fine powders.

Each type caters to specific industry needs and powder characteristics[1][4].

Why Choose Professional Powder Sieve System Suppliers?

Expertise and Customization

Professional suppliers offer tailored solutions to meet unique screening requirements. They provide customizable designs, including single, double, and triple deck configurations, ensuring maximum throughput and efficiency[2].

Advanced Technology Integration

Leading suppliers incorporate cutting-edge technologies such as multi-frequency vibration, ultrasonic deblinding, and automated screening systems. These innovations enhance screening accuracy, reduce downtime, and increase productivity[1][3][4].

Quality Assurance and Compliance

Reliable suppliers adhere to strict quality standards and certifications, ensuring that their sieve systems deliver consistent performance and comply with industry regulations. Many suppliers also provide after-sales support and maintenance services to maximize equipment lifespan.

Applications of Powder Sieve Systems

Chemical and Pharmaceutical Industries

Powder sieve systems ensure the removal of impurities and uniform particle size distribution, which is critical for product efficacy and safety in pharmaceuticals and chemicals[1][2].

Additive Manufacturing

In 3D printing and metal powder processing, precise sieving guarantees powder quality, improves print accuracy, and enables powder reuse. Automated and enclosed systems minimize operator exposure and enhance traceability[3].

Food and Metallurgy

Sieving ensures product purity and consistency in food powders and metal powders, improving process efficiency and final product quality[1][4].

Advantages of Partnering with a Chinese Powder Sieve System Manufacturer

Cost-Effectiveness

Chinese manufacturers offer competitive pricing without compromising quality, making them ideal partners for OEM services catering to global markets[6].

Advanced Manufacturing Capabilities

With investments in hydraulic forming, laser cutting, automatic welding, and mechanical processing centers, Chinese suppliers ensure high precision and scalability in production[6].

Extensive Product Range

From circular vibrating sieves to air flow sieves and linear sieves, manufacturers provide a wide variety of equipment suitable for different industries and applications[6].

Global Reach and Experience

Many Chinese powder sieve system suppliers export to over 50 countries, demonstrating their capability to meet diverse international standards and customer requirements[6].

How to Choose the Right Powder Sieve System Supplier?

Evaluate Technical Expertise

Look for suppliers with proven experience in your industry and the ability to customize solutions.

Assess Technology and Innovation

Choose suppliers who invest in advanced screening technologies like ultrasonic sieves and automated systems.

Consider After-Sales Support

Reliable technical support, easy maintenance, and availability of spare parts are critical for uninterrupted production.

Verify Quality Certifications

Ensure the supplier complies with relevant quality and safety standards.

Review Customer Feedback and Case Studies

Past performance and client testimonials provide insight into supplier reliability and service quality.

Future Trends in Powder Sieving Technology

Automation and Connectivity

Integration of IoT and cloud monitoring enables remote system optimization and real-time data logging, enhancing process control and traceability[3].

Enhanced Screening Efficiency

New materials and mesh designs improve throughput rates and reduce blinding, increasing overall productivity[2][4].

Sustainability Focus

Energy-efficient designs and recyclable materials are becoming priorities in sieve system manufacturing.

Frequently Asked Questions (FAQs)

Q1: What industries benefit most from powder sieve systems?

A1: Industries such as pharmaceuticals, chemicals, metallurgy, food processing, and additive manufacturing benefit significantly due to the need for precise particle size control and impurity removal[1][2][3].

Q2: How fine can powder sieve systems screen powders?

A2: Advanced systems can efficiently sieve powders down to 5-10 microns, depending on technology and mesh size[2][3].

Q3: What maintenance is required for powder sieve systems?

A3: Regular cleaning, screen mesh replacement, and periodic inspection of vibration motors or ultrasonic components are essential for optimal performance[2][4].

Q4: Can powder sieve systems be customized?

A4: Yes, many suppliers offer customizable configurations, including deck numbers, screen sizes, and automation levels to meet specific production needs[2][6].

Q5: What are the benefits of ultrasonic sieving technology?

A5: Ultrasonic sieving prevents mesh blinding, increases screening efficiency, and is ideal for fine and difficult-to-screen powders[4].

Conclusion

Choosing the right powder sieve system supplier is crucial for achieving high-quality, efficient powder screening. As a specialized Chinese manufacturer providing OEM services worldwide, we combine advanced technology, customization, and cost-effectiveness to meet diverse industry demands. Partnering with a reliable supplier ensures your production process is optimized for precision, productivity, and sustainability.

[1] https://elcanindustries.com/toll-processing/top-10-sieving-machines-screening-equipment-manufacturers-in-the-usa/

[2] https://elcanindustries.com/automatic-sieve-for-powders/

[3] https://www.russellfinex.com/en/separation-equipment/screening-machines/am-powder-sieving/

[4] https://www.hksieve.com/industries/industries/powder-metal-manufacturing/

[5] https://www.alibaba.com/showroom/sieve-for-fine-powder.html

[6] https://news.cnpowder.com.cn/70148.html

[7] https://www.acsmaterial.com/materials/molecular-sieves.html

[8] https://www.sefar.com/zh/818/%E5%B7%A5%E4%B8%9A%E8%BF%87%E6%BB%A4/%E8%AE%BE%E5%A4%87.htm?Folder=7255318

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.