Content Menu

● Understanding Powder Sieve Systems

>> What is a Powder Sieve System?

>> Types of Powder Sieve Systems

● Cost Factors in Powder Sieve Systems

>> Initial Investment

>> Operational Costs

>> Hidden Costs

● Cost-Benefit Analysis

>> Evaluating Return on Investment (ROI)

>> Case Studies

● Choosing the Right Powder Sieve System

>> Assessing Your Needs

>> Consulting with Experts

● Future Trends in Powder Sieve Systems

>> Technological Advancements

>> Sustainability Considerations

● Conclusion

>> Frequently Asked Questions

In the world of manufacturing and processing, the efficiency and effectiveness of powder handling can significantly impact overall productivity and product quality. One of the critical components in this process is the powder sieve system. This article delves into the cost analysis of powder sieve systems, exploring what businesses should expect when investing in these essential machines.

Understanding Powder Sieve Systems

What is a Powder Sieve System?

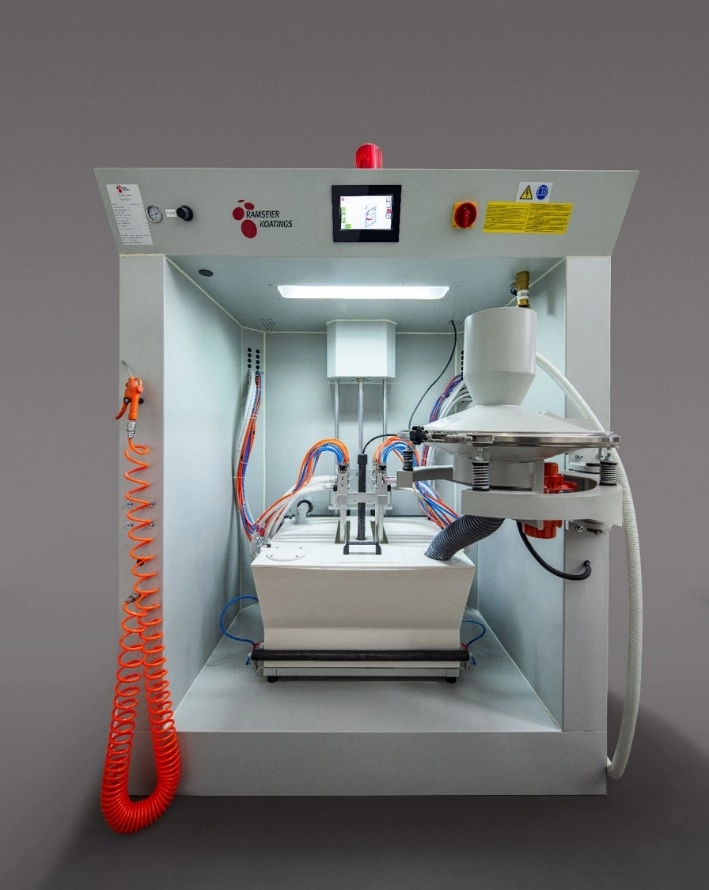

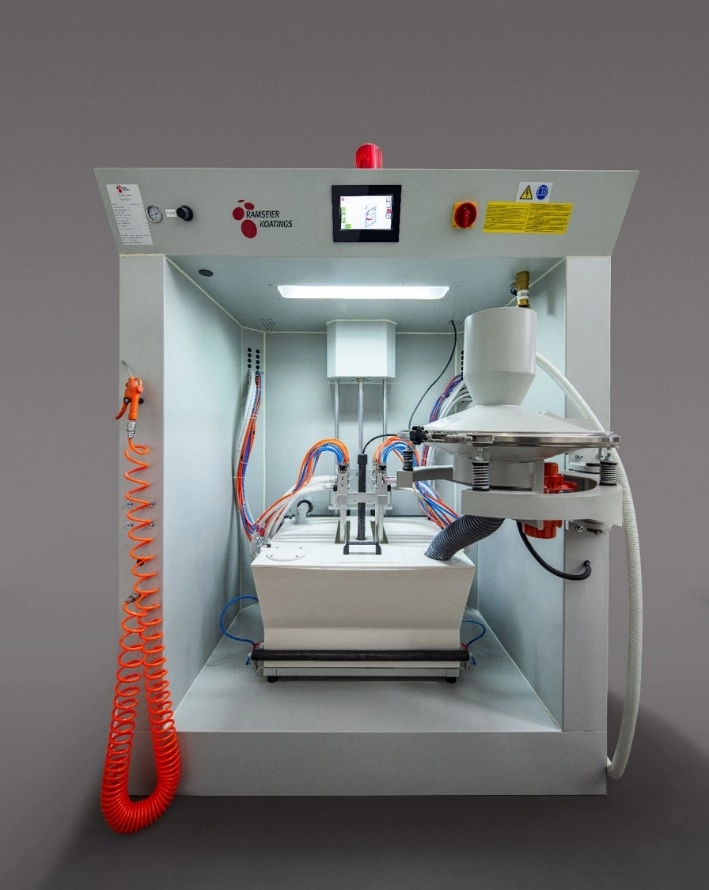

A powder sieve system is a mechanical device used to separate particles of different sizes in powdered materials. It is commonly employed in various industries, including pharmaceuticals, food processing, chemicals, and metallurgy. The primary function of a powder sieve is to ensure that the final product meets specific quality standards by removing oversized particles and contaminants.

Types of Powder Sieve Systems

There are several types of powder sieve systems available, each designed for specific applications:

- Vibrating Sieves: These use vibration to move powder through the sieve mesh, allowing for efficient separation.

- Rotary Sieves: These employ a rotating mechanism to push powder through the mesh, suitable for larger volumes.

- Ultrasonic Sieves: These incorporate ultrasonic technology to enhance the sieving process, particularly for fine powders that tend to clump.

Cost Factors in Powder Sieve Systems

When considering the purchase of a powder sieve system, several cost factors come into play. Understanding these can help businesses make informed decisions.

Initial Investment

The initial cost of a powder sieve system can vary widely based on several factors:

- Type of Sieve: Automated systems tend to be more expensive than manual ones. For instance, a basic manual sieve might cost a few thousand dollars, while an advanced automated system can exceed $30,000.

- Material and Build Quality: Sieve systems made from high-quality materials, such as stainless steel, are generally more expensive but offer better durability and hygiene.

- Brand and Manufacturer: Established brands may charge a premium for their products due to their reputation for quality and reliability.

Operational Costs

Beyond the initial investment, operational costs must also be considered:

- Energy Consumption: Automated systems typically consume more energy than manual ones, impacting long-term operational costs.

- Labor Costs: While automated systems reduce the need for manual labor, they may require skilled operators, which can increase labor costs.

- Maintenance and Repairs: Regular maintenance is essential to ensure optimal performance. The cost of parts and service can add up over time.

Hidden Costs

Several hidden costs can affect the overall expenditure on powder sieve systems:

- Training: Employees may require training to operate new systems effectively, which can incur additional costs.

- Downtime: If a system fails, the downtime can lead to significant losses in productivity and revenue.

- Compliance Costs: Industries such as pharmaceuticals and food processing often have strict regulatory requirements, which may necessitate additional investments in compliance measures.

Cost-Benefit Analysis

Evaluating Return on Investment (ROI)

When investing in a powder sieve system, it is crucial to evaluate the potential return on investment. This involves comparing the costs associated with the system against the benefits it provides:

- Increased Efficiency: A more efficient sieve system can lead to higher throughput, reducing the time and labor required for processing.

- Improved Product Quality: By ensuring consistent particle size and removing contaminants, businesses can enhance product quality, leading to higher customer satisfaction and potentially increased sales.

- Long-Term Savings: While the initial investment may be high, the long-term savings from reduced labor costs and increased efficiency can justify the expenditure.

Case Studies

To illustrate the impact of powder sieve systems, consider the following case studies:

1. Pharmaceutical Company: A pharmaceutical manufacturer invested in an automated powder sieve system, which increased their production capacity by 50%. The initial investment was recouped within two years due to increased sales and reduced labor costs.

2. Food Processing Plant: A food processing plant upgraded from a manual sieve to a vibrating sieve system. Although the upfront cost was significant, the improved efficiency and product quality led to a 30% increase in production, resulting in substantial revenue growth.

Choosing the Right Powder Sieve System

Assessing Your Needs

Before purchasing a powder sieve system, businesses should assess their specific needs:

- Production Volume: Higher production volumes may necessitate more advanced systems.

- Type of Material: Different materials may require different types of sieving technology.

- Budget Constraints: Understanding the budget will help narrow down options and avoid overspending.

Consulting with Experts

Engaging with industry experts or consultants can provide valuable insights into the best options available. They can help businesses understand the nuances of different systems and guide them toward making the most cost-effective choice.

Future Trends in Powder Sieve Systems

Technological Advancements

The powder sieve industry is continually evolving, with advancements in technology leading to more efficient and effective systems. Innovations such as smart sieving technology, which incorporates sensors and data analytics, are becoming more prevalent. These systems can provide real-time feedback and optimize performance, further enhancing efficiency.

Sustainability Considerations

As industries move towards more sustainable practices, powder sieve systems are also adapting. Manufacturers are increasingly focusing on energy-efficient designs and materials that reduce environmental impact. This shift not only meets regulatory requirements but also appeals to environmentally conscious consumers.

Conclusion

Investing in a powder sieve system is a significant decision that can impact a business's efficiency, product quality, and overall profitability. By understanding the various cost factors, conducting a thorough cost-benefit analysis, and choosing the right system for their needs, businesses can make informed decisions that lead to long-term success.

Frequently Asked Questions

1. What is the average cost of a powder sieve system?

The cost can range from a few thousand dollars for manual systems to over $30,000 for advanced automated systems.

2. How do I determine the right type of sieve for my business?

Assess your production volume, the type of material you are processing, and your budget to determine the best fit.

3. What are the ongoing costs associated with powder sieve systems?

Ongoing costs include energy consumption, maintenance, labor, and potential training for operators.

4. How can I evaluate the ROI of a powder sieve system?

Compare the initial investment and ongoing costs against the benefits, such as increased efficiency and improved product quality.

5. What trends are shaping the future of powder sieve systems?

Key trends include technological advancements, such as smart sieving technology, and a focus on sustainability in design and operation.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.