Content Menu

● Introduction

● What is a Powder Sieve System?

>> Key Components of a Powder Sieve System

● Why Choose Our Powder Sieve System Company for OEM Services?

>> Expertise in Customization

>> Advanced Technology Integration

>> Quality Assurance and Compliance

>> Global Reach and Support

● Applications of Powder Sieve Systems

>> Pharmaceutical Industry

>> Metallurgy and Additive Manufacturing

>> Food Processing

>> Chemical and Mineral Industries

● Advantages of Our Powder Sieve System

● How We Support OEM Clients

>> Collaborative Design Process

>> Prototyping and Testing

>> Flexible Production Capacity

>> After-Sales Service

● Frequently Asked Questions (FAQs)

● Conclusion

Introduction

As a leading Powder Sieve System Company based in China, we specialize in manufacturing and processing high-quality powder sieving systems. Serving global powder sieve system brand owners, wholesalers, and manufacturers, we provide comprehensive OEM services tailored to diverse industrial needs. Our expertise lies in delivering advanced, reliable, and customizable powder sieve systems that enhance production efficiency and product quality across various sectors.

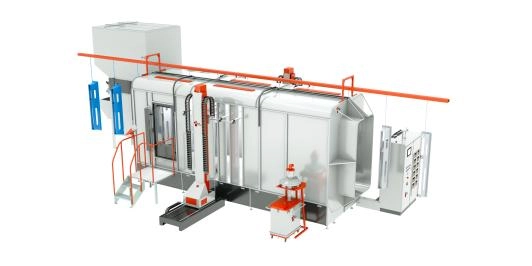

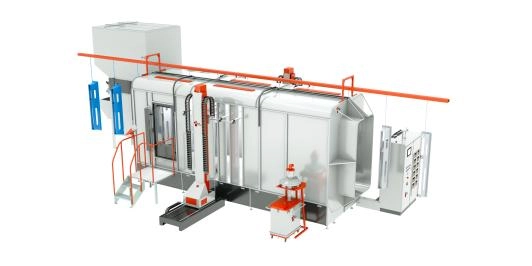

What is a Powder Sieve System?

A Powder Sieve System is an industrial machine designed to separate and classify powders based on particle size. It plays a critical role in ensuring product uniformity, removing contaminants, and improving the overall quality of powders used in industries such as pharmaceuticals, metallurgy, food processing, chemicals, and additive manufacturing.

Key Components of a Powder Sieve System

- Screen Mesh: The core element that filters powder particles by size.

- Vibratory Motor: Drives the sieving motion to facilitate powder separation.

- Collection Containers: Separate fine particles from oversize materials.

- Ultrasonic Technology (optional): Enhances sieving efficiency by preventing mesh blinding, especially for fine powders.

Why Choose Our Powder Sieve System Company for OEM Services?

Expertise in Customization

Our Powder Sieve System Company offers highly customizable solutions to meet the specific requirements of our clients. Whether it's adapting mesh sizes, vibration frequencies, or integrating ultrasonic sieving technology, we tailor our systems for optimal performance in your production environment.

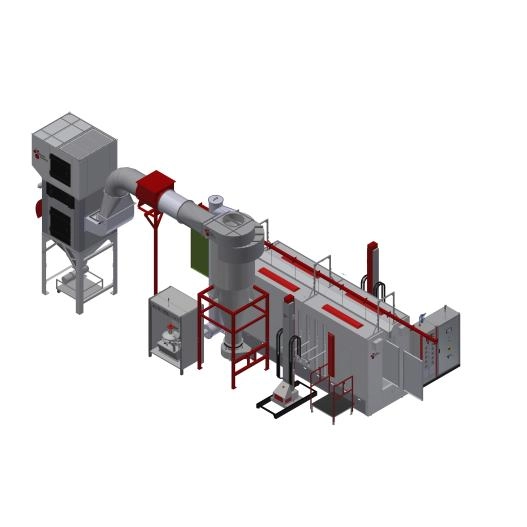

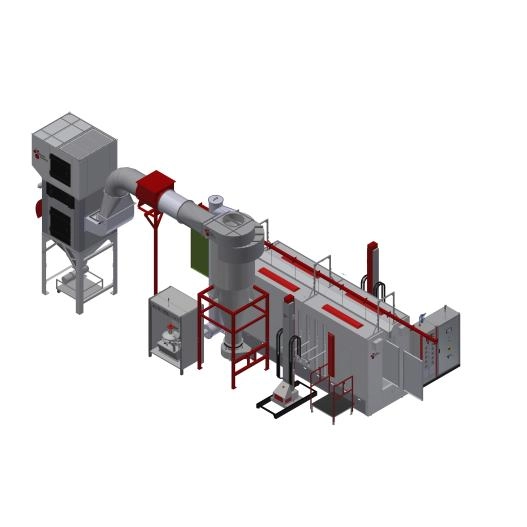

Advanced Technology Integration

We incorporate cutting-edge technologies such as ultrasonic sieving and intelligent control systems to improve sieving accuracy and efficiency. For example, ultrasonic sieving systems help maintain high powder quality by effectively removing oversized particles and contaminants, which is crucial for industries like metal 3D printing.

Quality Assurance and Compliance

Our manufacturing processes adhere to stringent quality standards, ensuring that our powder sieve systems meet international certifications and hygiene requirements. This is especially important for sectors like food and pharmaceuticals, where contamination control is critical.

Global Reach and Support

We have established a robust supply chain and after-sales support network that caters to over 50 countries worldwide. Our clients benefit from timely delivery, installation assistance, and technical support to ensure seamless integration of our powder sieve systems into their production lines.

Applications of Powder Sieve Systems

Pharmaceutical Industry

Powder sieving ensures the removal of lumps and contaminants in pharmaceutical powders, maintaining product purity and consistency. Our systems comply with strict hygiene standards required in this sector.

Metallurgy and Additive Manufacturing

In metal powder production for 3D printing, precise particle size distribution is vital. Our ultrasonic powder sieve systems help achieve narrow size ranges and remove impurities, enhancing the quality of printed components.

Food Processing

Powder sieve systems are used for grading and contaminant removal in food powders like flour, sugar, and spices. Our systems are designed to meet food safety regulations and ensure product quality.

Chemical and Mineral Industries

Sieving is essential for classifying powders and removing oversized particles in chemical and mineral processing. Our systems improve product consistency and reduce waste.

Advantages of Our Powder Sieve System

| Feature | Benefit |

| Ultrasonic Sieving Technology | Prevents mesh blinding, increases throughput, improves powder quality |

| Customizable Designs | Tailored to meet specific production needs and powder characteristics |

| High-Efficiency Motors | Low energy consumption and long maintenance intervals |

| Hygienic Construction | Easy to clean and maintain, suitable for food and pharma |

| Intelligent Control Systems | One-click operation for enhanced efficiency and safety |

How We Support OEM Clients

Collaborative Design Process

We work closely with brand owners and manufacturers to understand their unique production challenges and design powder sieve systems that integrate seamlessly into their workflows.

Prototyping and Testing

Before full-scale production, prototypes undergo rigorous testing to ensure performance meets client specifications and industry standards.

Flexible Production Capacity

Our factory is equipped to handle both small-batch custom orders and large-scale manufacturing, ensuring timely delivery regardless of order size.

After-Sales Service

We provide comprehensive after-sales support, including installation guidance, maintenance training, and spare parts supply to maximize system uptime.

Frequently Asked Questions (FAQs)

Q1: What industries benefit most from powder sieve systems?

A1: Industries such as pharmaceuticals, metallurgy, food processing, chemicals, and additive manufacturing rely heavily on powder sieve systems to ensure product quality and consistency.

Q2: How does ultrasonic sieving improve powder screening?

A2: Ultrasonic sieving prevents mesh blinding by vibrating the screen at high frequencies, allowing finer powders to pass through more efficiently, which enhances throughput and powder quality.

Q3: Can your powder sieve systems handle reactive metal powders?

A3: Yes, certain systems are designed to operate under inert gas atmospheres like argon, ensuring safe sieving of reactive powders such as titanium.

Q4: What customization options are available for OEM clients?

A4: Customizations include mesh size, vibration frequency, system size, integration of ultrasonic technology, and control system features to meet specific production requirements.

Q5: How do you ensure compliance with hygiene standards in food and pharmaceutical applications?

A5: Our systems are designed with hygienic materials and easy-to-clean structures, meeting standards such as 3-A, NZFSA, and EHEDG for sanitary processing.

Conclusion

As a dedicated Powder Sieve System Company, we pride ourselves on delivering high-quality, customizable powder sieving solutions that meet the rigorous demands of various industries worldwide. Our OEM services empower global brands and manufacturers to optimize their powder processing with advanced technology, reliable performance, and comprehensive support.

Come and contact us to shop! ! !

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.