Content Menu

● Introduction

● Understanding the WX-958 Powder Coating System

>> What is the WX-958 Powder Coating System?

>> Key Components of the WX-958 System

● How to Set Up the WX-958 Powder Coating System

>> Step-by-Step Assembly Guide

>> Important Setup Tips

● Operating the WX-958 Powder Coating System

>> Basic Operation Modes

>> Adjusting Settings for Best Results

>> Maintenance During Operation

● Troubleshooting Common Issues with the WX-958 Powder Coating System

>> Problem: Uneven Coating or Poor Adhesion

>> Problem: Powder Clogging or Irregular Spray

>> Problem: Machine Fails to Power On

● Advantages of Using the WX-958 Powder Coating System for OEM Services

● Frequently Asked Questions (FAQs)

● Conclusion

Introduction

As a leading Chinese manufacturer, wholesaler, and supplier specializing in powder coating systems, we provide OEM services to international brands, wholesalers, and producers. This article serves as an extensive guide on the WX-958 powder coating system manual, detailing its setup, operation, maintenance, and optimization to help users maximize efficiency and quality in powder coating applications.

Understanding the WX-958 Powder Coating System

What is the WX-958 Powder Coating System?

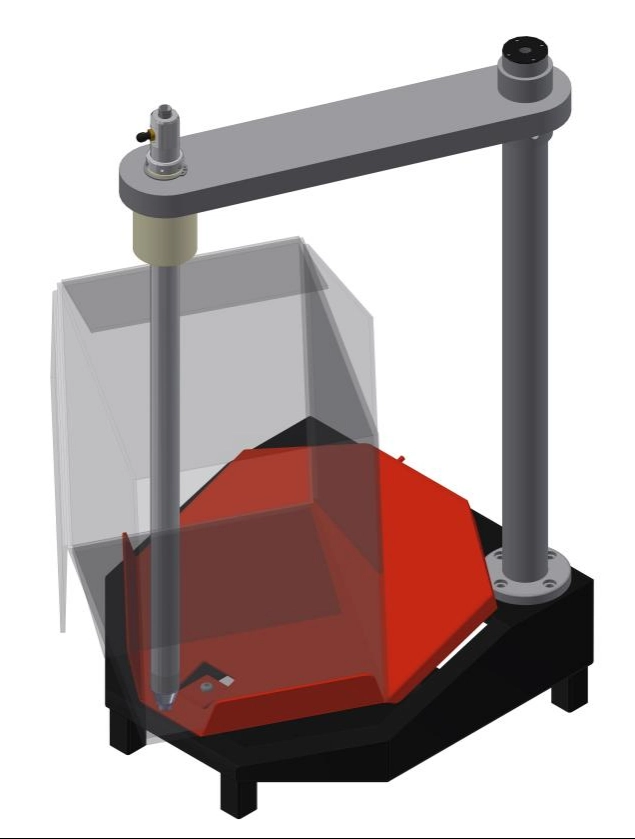

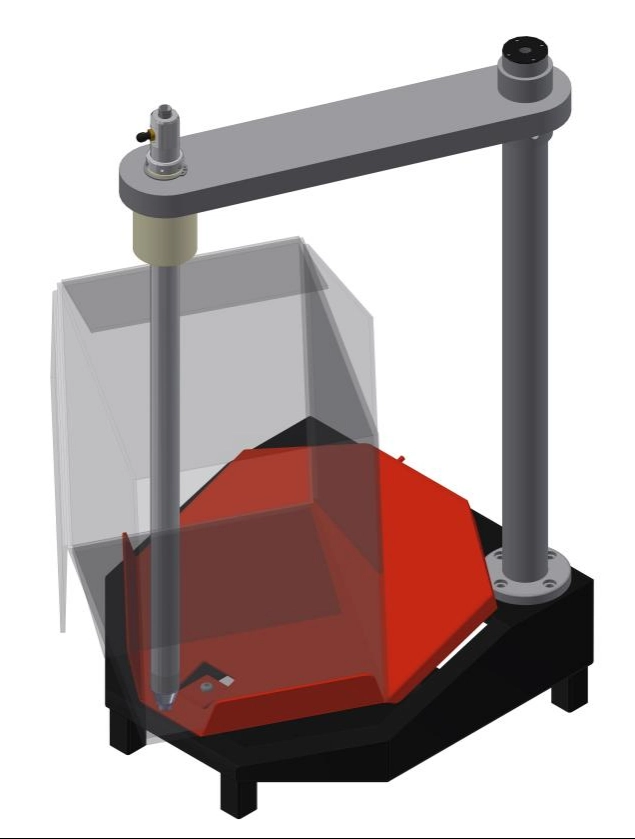

The WX-958 powder coating system is a high-performance electrostatic powder coating machine widely used in industrial and DIY applications. It features a 45-liter stainless steel powder bucket, adjustable voltage and air pressure settings, and various nozzles for different coating patterns[3]. This system is designed for durability, ease of use, and flexibility, making it ideal for OEM manufacturers and suppliers seeking reliable powder coating solutions.

Key Components of the WX-958 System

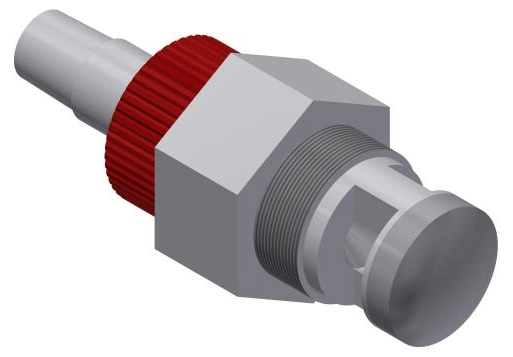

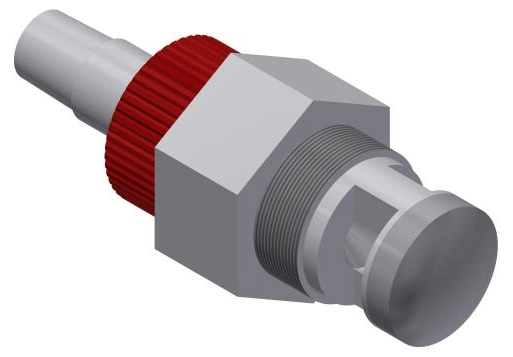

- Electrostatic Gun: The core component that charges powder particles for efficient adhesion to surfaces[4].

- Powder Bucket: Made of high-quality stainless steel to resist rust and corrosion, ensuring longevity and consistent powder supply[3].

- Control Panel: Includes power, air, rinsing air, kV (kilovolts), and uA (microamps) buttons for precise operation[3].

- Nozzles: Multiple nozzle types allow for spray diffusion or fan-shaped coating, adaptable to various project needs[3].

- Air and Fluidizing System: Regulates powder flow and fluidization for smooth and even coating application[5].

How to Set Up the WX-958 Powder Coating System

Step-by-Step Assembly Guide

1. Unpack and Inspect: Ensure all parts and accessories are included as per the manual.

2. Connect Air Lines: Attach air hoses to the corresponding fittings on the gun and powder bucket. The air input controls powder fluidization and spray pressure[2][5].

3. Install Powder Bucket: Secure the stainless steel bucket onto the machine and connect it to the gun via the powder supply hose[5].

4. Attach Electrostatic Gun: Connect the gun to the control unit and air supply lines, including the rinsing air hose for cleaning[5].

5. Power On and Calibration: Turn on the machine and adjust settings such as voltage (typically around 40 kV) and air pressure (around 10 psi) according to project requirements[2][5].

Important Setup Tips

- Use a regulator gauge set to about 50 psi for optimal air pressure[2].

- Gradually adjust the fluidization valve to avoid powder clumping or excessive flow[5].

- Regularly check hose connections to prevent leaks and ensure consistent powder delivery[5].

Operating the WX-958 Powder Coating System

Basic Operation Modes

- Manual Trigger Mode: Operator controls powder spray by pulling the trigger, suitable for small or detailed jobs[5].

- Continuous Mode: Automatic powder spray for large-scale industrial applications[5].

Adjusting Settings for Best Results

- Voltage (kV): Controls the electrostatic charge on powder particles; typical settings range from 20 to 100 kV depending on coating thickness and substrate[2][5].

- Air Pressure: Adjust both spray air and rinsing air to maintain smooth powder flow and prevent clogging[3][5].

- Nozzle Selection: Choose between fan-shaped or diffusion spray nozzles based on the surface area and detail of the item being coated[3].

Maintenance During Operation

- Periodically rinse the gun using the rinsing air function to prevent powder buildup[5].

- Monitor powder levels and refill the bucket as needed to avoid interruptions[3].

Troubleshooting Common Issues with the WX-958 Powder Coating System

Problem: Uneven Coating or Poor Adhesion

- Check electrostatic voltage settings; increase kV if powder is not adhering well[2].

- Ensure powder is properly fluidized; adjust air pressure and fluidization valve[5].

- Clean the gun nozzle to remove any blockages[5].

Problem: Powder Clogging or Irregular Spray

- Inspect and clean air and powder hoses for obstructions[5].

- Verify that the powder bucket is not overloaded and powder is dry[3].

- Adjust air pressure settings to optimize powder flow[2].

Problem: Machine Fails to Power On

- Confirm power supply and connections are secure[3].

- Check for blown fuses or electrical faults in the control unit[4].

- Consult the manual for resetting procedures[1].

Advantages of Using the WX-958 Powder Coating System for OEM Services

- Customizable Settings: Allows precise control over coating parameters to meet diverse client specifications.

- Durability: Stainless steel components and robust design ensure long-term use with minimal maintenance[3].

- Mobility: Equipped with universal wheels for easy movement around the production floor[3].

- Versatility: Suitable for various powder types and coating styles, enhancing product range for OEM customers[3].

- Ease of Use: Intuitive controls and straightforward assembly reduce training time and increase productivity[2][5].

Frequently Asked Questions (FAQs)

Q1: What is the ideal voltage setting for the WX-958 powder coating system?

A1: The ideal voltage typically ranges from 20 to 40 kV for most applications, but it can be adjusted up to 100 kV depending on the powder type and substrate[2][5].

Q2: How often should the powder bucket be cleaned?

A2: The powder bucket should be cleaned regularly, especially when changing powder colors or after extended use, to prevent contamination and ensure smooth operation[5].

Q3: Can the WX-958 system handle different powder types?

A3: Yes, the system is compatible with various powder coatings, including polyester and epoxy powders, thanks to its adjustable settings and interchangeable nozzles[3][4].

Q4: Is the WX-958 suitable for both industrial and DIY use?

A4: Absolutely, it offers modes for both continuous industrial coating and manual operation for smaller, detailed DIY projects[2][5].

Q5: What maintenance is required to keep the WX-958 in good condition?

A5: Regular cleaning of the gun and hoses, checking air pressure settings, and inspecting electrical connections are essential to maintain optimal performance[5].

Conclusion

The WX-958 powder coating system manual is an indispensable resource for manufacturers, wholesalers, and suppliers seeking to deliver high-quality powder coating services. Its robust design, versatile features, and user-friendly controls make it an excellent choice for OEM production lines. By following the setup, operation, and maintenance guidelines outlined above, users can ensure efficient, consistent, and professional powder coating results.

[1] https://www.scribd.com/document/327401652/WX-958-instructions1

[2] https://www.youtube.com/watch?v=CSsjo2I2Us8

[3] https://www.vevor.com/powder-coating-machine-c_11089/45l-powder-coating-system-machine-electrostatic-deep-corners-paint-system-wx-958-p_010402503015

[4] https://xintu2011.en.made-in-china.com/product/dXqmRibukFUw/China-Wx-958-Powder-Spraying-Gun-Electrostatic-Manual-Powder-Coating-Equipment.html

[5] https://www.youtube.com/watch?v=0a_Wx-XLhyY

[6] http://www.sse.com.cn/disclosure/listedinfo/announcement/c/new/2025-04-29/688128_20250429_IZYA.pdf

[7] https://www.alibaba.com/product-detail/WX-958-Manual-50W-Paint-System_1601059957779.html

[8] https://kjt.ln.gov.cn/kjt/attachDir/2025/01/2025012510161058280.xlsx

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.