Content Menu

● Comprehensive Guide to Choosing the Right Powder Sieve System Manufacturing Company for OEM Services

>> Introduction

● What is a Powder Sieve System Manufacturing Company?

● Why Choose a Professional Powder Sieve System Manufacturing Company for OEM?

>> Expertise in Advanced Sieving Technology

>> Customization and Flexibility

>> Quality Assurance and Compliance

● Key Technologies Used by a Powder Sieve System Manufacturing Company

>> Vibratory Screeners

>> Ultrasonic Sieving Systems

>> Air Classifiers

● Industries Served by a Powder Sieve System Manufacturing Company

>> Additive Manufacturing

>> Pharmaceutical Industry

>> Food Processing

>> Metallurgy

● Benefits of Partnering with a Powder Sieve System Manufacturing Company for OEM

● How to Select the Right Powder Sieve System Manufacturing Company

>> Evaluate Technical Capabilities

>> Check Customization Options

>> Review Quality Certifications

>> Assess After-Sales Support

>> Consider Industry Experience

● Frequently Asked Questions (FAQs)

Comprehensive Guide to Choosing the Right Powder Sieve System Manufacturing Company for OEM Services

Introduction

In today's fast-evolving industrial landscape, precision and efficiency in powder processing are critical. As a Powder Sieve System Manufacturing Company, we specialize in providing OEM services to international powder sieve system brands, wholesalers, and manufacturers. This article explores the vital role of a powder sieve system manufacturing company, the technology involved, and how partnering with a reliable manufacturer can elevate your product quality and operational efficiency.

What is a Powder Sieve System Manufacturing Company?

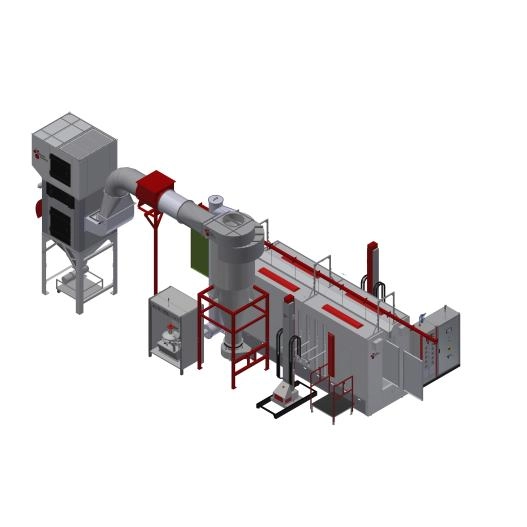

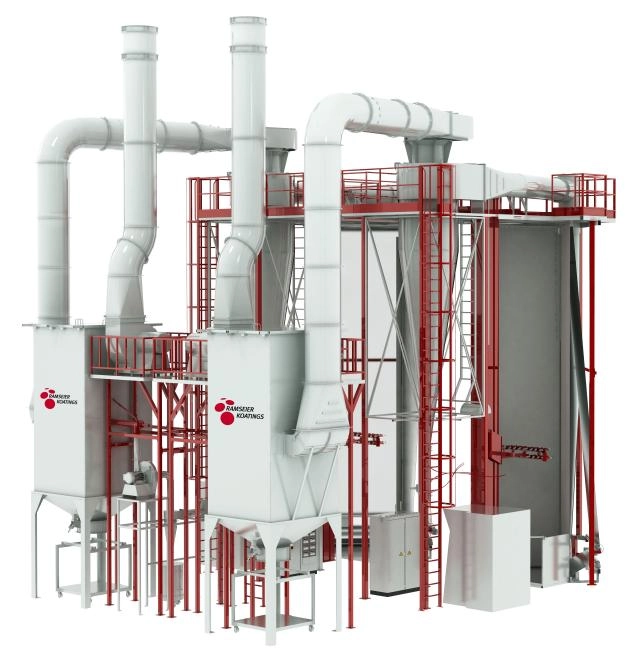

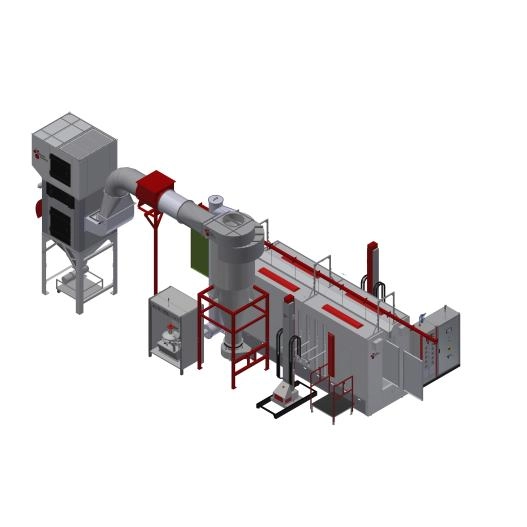

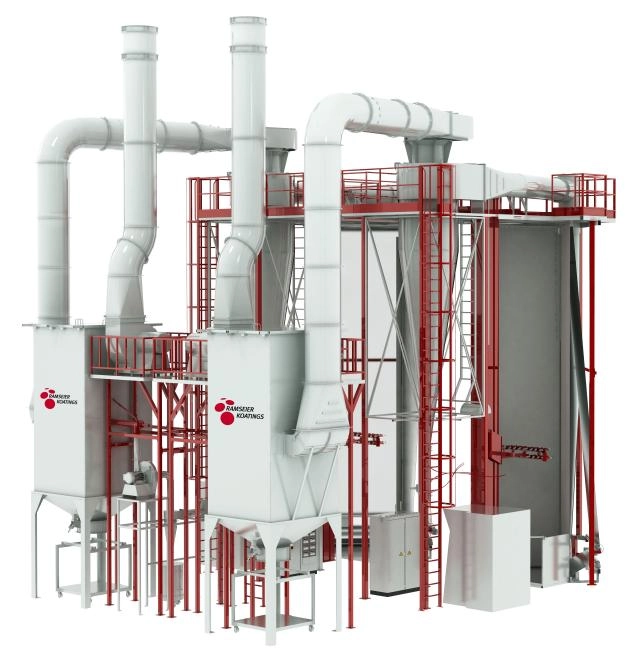

A Powder Sieve System Manufacturing Company designs, develops, and produces specialized equipment used to separate and classify powders by particle size. These systems are essential in various industries including pharmaceuticals, food processing, metallurgy, and additive manufacturing. The manufacturing company provides tailored OEM services, enabling foreign brands and distributors to source customized powder sieving solutions that fit their unique production requirements.

Why Choose a Professional Powder Sieve System Manufacturing Company for OEM?

Expertise in Advanced Sieving Technology

A reputable Powder Sieve System Manufacturing Company leverages advanced technology such as ultrasonic sieving, vibratory screeners, and air classifiers to ensure precise particle separation and high throughput rates. For example, ultrasonic metal powder sieving systems can handle reactive materials like titanium safely under protective gas environments, ensuring high powder quality for additive manufacturing.

Customization and Flexibility

OEM services allow brands to customize sieve systems according to their specifications, including mesh size, material compatibility, and production capacity. This flexibility is crucial for meeting the diverse needs of industries such as powder metallurgy, pharmaceuticals, and food processing.

Quality Assurance and Compliance

Manufacturers maintain strict quality control standards and ensure their equipment complies with international safety and hygiene regulations. This is particularly important for sectors like pharmaceuticals and food, where contamination risks must be minimized.

Key Technologies Used by a Powder Sieve System Manufacturing Company

Vibratory Screeners

Vibratory screeners are widely used for their efficiency in separating powders with high accuracy and throughput. They utilize high-frequency vibrations to prevent screen blinding and ensure consistent particle size distribution.

Ultrasonic Sieving Systems

Ultrasonic sieving enhances the screening process by applying ultrasonic waves to the mesh, which helps in deblinding and improves the flow of fine powders. This technology is especially beneficial for fine metal powders used in 3D printing and additive manufacturing.

Air Classifiers

Innovative air classifiers, such as the Elbow Jet Air Classifier, use aerodynamic principles to separate particles without moving parts, providing precise classification for abrasive and high-purity powders.

Industries Served by a Powder Sieve System Manufacturing Company

Additive Manufacturing

In additive manufacturing, powder quality directly affects the final product. A Powder Sieve System Manufacturing Company supplies systems that ensure powders have a narrow size distribution and are free from contaminants, improving print quality and reducing waste.

Pharmaceutical Industry

Pharmaceutical powders require stringent sieving to meet hygiene standards and ensure product uniformity. Advanced sieve systems help maintain compliance while optimizing production efficiency.

Food Processing

Powder sieving in food production removes lumps and contaminants, enhancing product quality and safety. Vibratory sieves are commonly used to handle large-scale food powder processing.

Metallurgy

Metal powder manufacturers rely on specialized sieving systems to achieve accurate particle size distribution, which is critical for powder metallurgy processes and recycling of powders.

Benefits of Partnering with a Powder Sieve System Manufacturing Company for OEM

- Cost Efficiency: OEM partnerships reduce development costs by leveraging the manufacturer's expertise and production capabilities.

- Scalability: Manufacturers can accommodate large-scale production runs with consistent quality.

- Innovation Access: Clients benefit from the latest sieving technologies and continuous R&D improvements.

- Global Reach: Many manufacturers export equipment worldwide, supporting international brands with local service and support.

How to Select the Right Powder Sieve System Manufacturing Company

Evaluate Technical Capabilities

Ensure the manufacturer offers a range of sieving technologies suitable for your powder type and production scale.

Check Customization Options

A good partner will provide tailored OEM solutions, including design, material selection, and integration support.

Review Quality Certifications

Verify compliance with industry standards and certifications relevant to your sector.

Assess After-Sales Support

Reliable technical support and maintenance services are crucial for minimizing downtime.

Consider Industry Experience

Manufacturers with a proven track record in your industry can better understand and meet your specific needs.

Frequently Asked Questions (FAQs)

Q1: What industries benefit most from powder sieve systems?

A1: Industries such as pharmaceuticals, food processing, metallurgy, and additive manufacturing benefit significantly from precise powder sieving.

Q2: Can a powder sieve system handle reactive metal powders safely?

A2: Yes, ultrasonic sieving systems designed to operate under inert gases like argon ensure safe handling of reactive powders such as titanium.

Q3: How does ultrasonic sieving improve powder screening?

A3: Ultrasonic sieving applies high-frequency vibrations to prevent mesh blinding and improve the flow of fine powders, enhancing screening efficiency.

Q4: What is the advantage of OEM services from a powder sieve system manufacturer?

A4: OEM services allow customization, cost savings, and access to advanced technology tailored to specific production needs[6].

Q5: How do powder sieve systems contribute to product quality?

A5: They remove contaminants, ensure uniform particle size distribution, and comply with hygiene standards, thus improving overall product quality.

Come and contact us to shop! ! !

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.