Content Menu

● Understanding Rotary Sieves

>> What Are Rotary Sieves?

>> Principle of Operation

>> Design Features

>> Applications and Limitations

● Overview of Our Powder Sieve System

>> What Is Our Powder Sieve System?

>> Principle of Operation

>> Design Features

>> Advantages Over Rotary Sieves

● Detailed Comparison: Our Powder Sieve System vs. Rotary Sieves

● Operational Considerations

>> Efficiency and Throughput

>> Maintenance and Usability

>> Contamination and Quality Control

● Applications Where Our Powder Sieve System Excels

● Frequently Asked Questions

>> 1. What is the main operational difference between rotary sieves and our powder sieve system?

>> 2. Can rotary sieves handle fragile powders without damaging them?

>> 3. How does maintenance compare between the two systems?

>> 4. Are multiple screening levels possible with rotary sieves?

>> 5. Which system offers better contamination control?

In the world of industrial powder processing, efficient and accurate sieving is critical to ensuring product quality, consistency, and safety. Among the various sieving technologies available, rotary sieves and powder sieve systems are commonly used for screening powders and granular materials. This article explores how our powder sieve system differs from traditional rotary sieves, highlighting the operational principles, design features, advantages, and typical applications of each. By understanding these differences, manufacturers can make informed decisions about which technology best suits their production needs.

Understanding Rotary Sieves

What Are Rotary Sieves?

Rotary sieves, also known as centrifugal sifters, are screening machines that use centrifugal force to separate powder particles and granules based on size. The core of a rotary sieve consists of a cylindrical sieving chamber with rotating paddles or a screw conveyor shaft fitted with paddles. Material is fed into the chamber, where the paddles propel it against a screen mesh. Fine particles pass through the screen, while oversized particles are pushed to the end of the chamber and discharged separately[1][5][6].

Principle of Operation

The rotary sieve operates by feeding bulk powder into an inlet where a small auger or rotating paddles push the material into the cylindrical sieving chamber. The centrifugal force generated by the rotation accelerates finer particles through the screen apertures. Oversized particles or contaminants are forced to the end of the chamber and discharged through a separate outlet. Brushes or other cleaning mechanisms prevent the screen from clogging during operation[1][5].

Design Features

- Elongated housing with a motor on one end and bearing on the other.

- Two material discharge outlets: one for in-spec fine powder and one for oversized rejects.

- Off-center inlet and outlet to optimize material flow.

- Access doors for screen inspection and maintenance.

- Screen types: nylon cloth, woven wire, perforated plates, and stainless steel mesh.

- Drive mechanisms: direct, indirect, or belt-driven motors.

- Air purge seals to protect bearings from powder contamination[2][5][6][8].

Applications and Limitations

Rotary sieves are widely used at the beginning of material handling processes to remove foreign bodies and protect downstream equipment. They are effective at de-agglomerating powders and handling high capacities in a compact footprint. However, rotary sieves can cause mechanical stress on powders, potentially leading to particle breakage, which limits their use for delicate materials. Also, they typically accommodate only one screen at a time, restricting simultaneous multi-level screening[6][8].

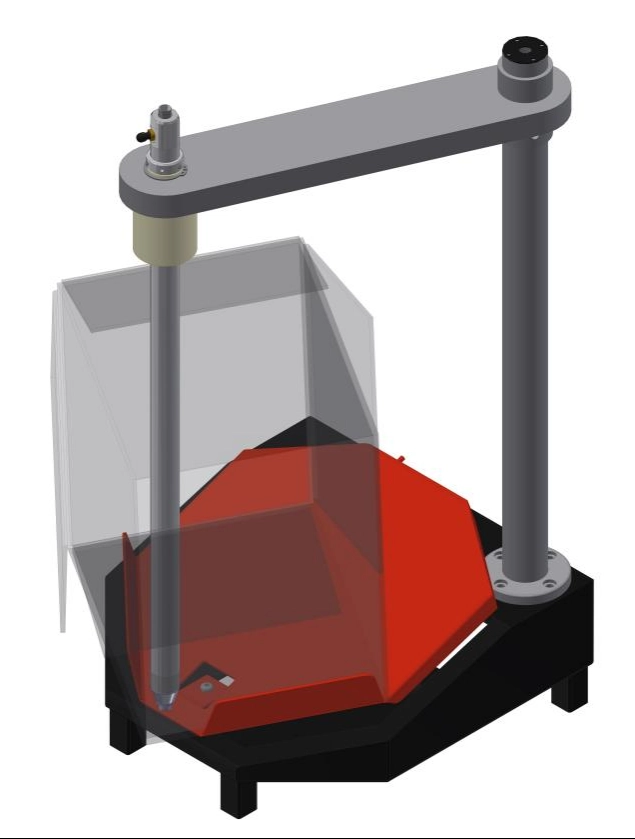

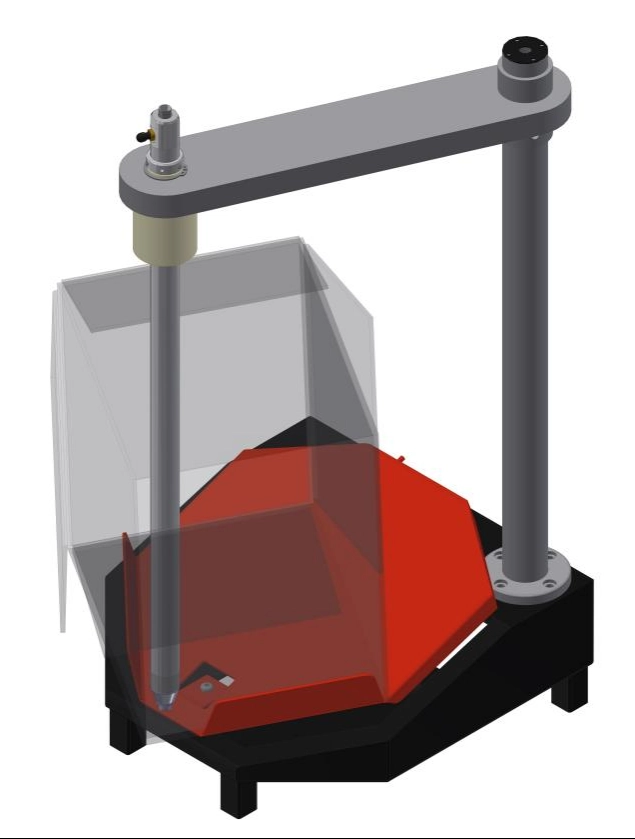

Overview of Our Powder Sieve System

What Is Our Powder Sieve System?

Our powder sieve system is a modern alternative designed to optimize powder screening by combining innovative mechanisms with user-friendly features. Unlike rotary sieves that rely on centrifugal force and rotating paddles, our system often employs vibratory or other advanced sieving technologies to gently and efficiently separate powders based on particle size.

Principle of Operation

The powder sieve system uses vibration or other mechanical agitation methods to encourage powder particles to pass through the mesh screens. This movement helps prevent clumping and screen blinding while ensuring a consistent screening process. The system typically features inline feed and discharge, with the inlet and outlet aligned for smoother material flow[4][8].

Design Features

- Vibratory or flat deck screening technology that agitates powders without rotating parts.

- Inlet and outlet aligned in line, facilitating straightforward integration into production lines.

- Stacked screen decks for multi-level classification if needed.

- Quick-release clamping mechanisms for easy screen changes and cleaning.

- Compact design with lower height compared to rotary sieves, saving installation space.

- Fabrication materials include mild steel, 304, and 316 stainless steel with various mesh options[4][7][8].

Advantages Over Rotary Sieves

- Operator-friendly design: Easier to disassemble, inspect, and maintain.

- Reduced risk of mesh damage: No rotating paddles pressing material against the screen.

- Better contamination control: Less mechanical stress reduces the chance of mesh rupture and product contamination.

- Gentler on powders: Suitable for fragile or sensitive materials that might break in rotary sieves.

- Higher screening efficiency: Multi-deck options allow simultaneous classification of different particle sizes[4][8].

Detailed Comparison: Our Powder Sieve System vs. Rotary Sieves

| Feature | Rotary Sieves (Centrifugal Sifters) | Our Powder Sieve System (Vibratory/Advanced Sieves) |

| Screening Mechanism | Centrifugal force with rotating paddles pushing material against screen | Vibratory or mechanical agitation without rotating parts |

| Material Flow | Off-center inlet and outlet; material pushed by paddles | Inlet and outlet aligned inline for smooth flow |

| Screen Capacity | Single screen at a time | Multiple stacked screens possible for multi-level classification |

| Maintenance | Access doors but more complex disassembly | Quick-release clamps allow easy screen changes and cleaning |

| Powder Handling | Can cause mechanical stress and particle breakage | Gentler on powders, suitable for fragile materials |

| Contamination Control | Risk of mesh damage and contamination from mechanical stress | Better contamination control due to less aggressive screening |

| Installation Footprint | Compact but taller due to elongated housing | Lower height, saves installation space |

| Typical Applications | High-capacity bulk powder screening, de-agglomeration, contamination removal | Bulk powder screening, classification, delicate material handling |

Operational Considerations

Efficiency and Throughput

Rotary sieves excel in high-capacity operations where rapid de-agglomeration and contamination removal are priorities. Their centrifugal action enables fast screening but may compromise powder integrity. Our powder sieve system prioritizes product quality and screening precision, making it ideal for processes requiring gentle handling and multi-level classification.

Maintenance and Usability

The complexity of rotary sieve maintenance, especially screen replacement and cleaning, can lead to longer downtime. Our system's design emphasizes operator convenience with quick-release mechanisms and easier access, reducing maintenance time and improving overall productivity.

Contamination and Quality Control

Rotary sieves' mechanical stress can damage screen meshes, potentially allowing contaminants to pass undetected. Our powder sieve system's gentler operation minimizes mesh damage and enhances contamination control, aligning with stricter quality standards and regulatory compliance.

Applications Where Our Powder Sieve System Excels

- Pharmaceutical powder screening requiring gentle handling to preserve particle integrity.

- Food industry applications demanding stringent contamination control and easy cleaning.

- Chemical and fine materials processing where multi-level particle classification is needed.

- Situations where space constraints favor compact, low-height equipment.

- Processes requiring quick changeovers and minimal downtime for maintenance.

Frequently Asked Questions

1. What is the main operational difference between rotary sieves and our powder sieve system?

Rotary sieves use centrifugal force with rotating paddles to push material through the screen, while our powder sieve system typically uses vibratory or mechanical agitation without rotating parts, resulting in gentler and more precise screening.

2. Can rotary sieves handle fragile powders without damaging them?

Rotary sieves may cause mechanical stress leading to particle breakage, making them less suitable for fragile powders. Our powder sieve system is designed to handle delicate materials more gently.

3. How does maintenance compare between the two systems?

Our powder sieve system features quick-release clamping and easier access for screen changes, reducing downtime. Rotary sieves require more complex disassembly and inspection.

4. Are multiple screening levels possible with rotary sieves?

Rotary sieves generally accommodate only one screen at a time, limiting multi-level classification. Our powder sieve system can have stacked decks for simultaneous multi-level screening.

5. Which system offers better contamination control?

Our powder sieve system provides better contamination control due to less mechanical stress on the screen mesh, reducing the chance of mesh damage and product contamination.

[1] https://blog.praterindustries.com/sieving-techniques-industrial-sieves-vs.-rotary-sifters

[2] https://www.palamaticprocess.com/en-us/blog/centrifugal-sieve-or-vibrating-sieve-which-one-to-choose

[3] https://www.russellfinex.com/en/news-and-events/rotary-sifter-vs-vibratory-sieve/

[4] https://www.processindustryinformer.com/rotary-sieves-best-option-bulk-powder-sieving/

[5] https://www.palamaticprocess.com/en-us/blog/5-things-to-know-about-a-centrifugal-sifter

[6] https://powderprocess.net/Equipments%20html/Rotary_Sifter.html

[7] https://fzsn.virtogroup.com/how-to-choose-between-a-rotary-sieve-and-a-circular-vibrating-screen/

[8] https://www.palamaticprocess.com/en-ca/differences-between-vibrating-sieve-and-a-centrifugal-sieve

[9] https://www.nordson.com/en/products/industrial-coating-systems-products/nrps-200rotary-powder-coating-sieve

[10] https://www.palamaticprocess.com/blog/centrifugal-sieve-or-vibrating-sieve-which-one-to-choose

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.