Content Menu

● Introduction

● Understanding Sieving Technologies

>> What is a Centrifugal Sieve?

>> How Does Our Powder Sieve System Work?

● Comparing Precision in Particle Separation

>> Consistency of Force Application

>> Mesh and Screen Technology

>> Prevention of Screen Blinding

● Operational Advantages Influencing Precision

>> Throughput Capacity and Efficiency

>> Dust Control and Hygiene

>> Maintenance and Reliability

>> Noise and Vibration Levels

● Application Suitability and Material Considerations

>> Handling Fragile and High-Precision Powders

>> Versatility Across Industries

● Summary of Comparative Features

● Conclusion

● Related Questions and Answers

Introduction

In industries that handle powders and fine granules, precision in particle size separation is crucial. Efficient sieving ensures product quality, consistency, and safety across sectors such as pharmaceuticals, food processing, chemicals, and nutraceuticals. Among the various sieving technologies available, centrifugal sieves have gained popularity due to their high accuracy and efficiency. However, advances in powder sieve systems have introduced alternatives that claim to offer even greater precision. This article explores whether our powder sieve system provides more precision than traditional centrifugal sieves by examining their working principles, design features, operational performance, and application suitability.

Understanding Sieving Technologies

What is a Centrifugal Sieve?

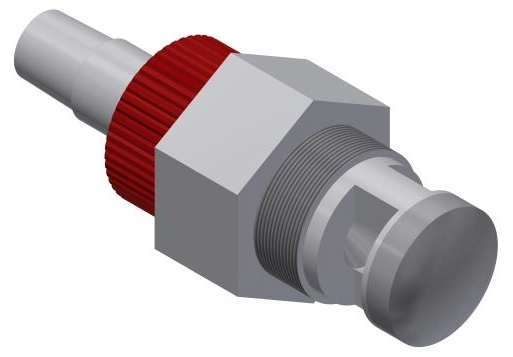

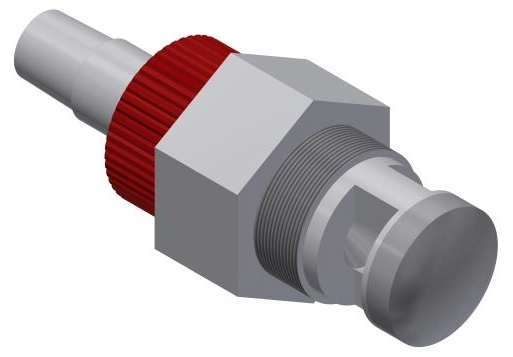

Centrifugal sieves, also known as rotary sifters, utilize centrifugal force generated by spinning paddles inside a cylindrical screening chamber. Powder is fed into the chamber where rotating paddles propel the material against a mesh screen. Finer particles pass through the screen into a discharge hopper, while oversized particles are pushed to a rejection outlet and removed from the process. The spinning motion typically ranges from 600 to 700 RPM, providing consistent and uniform force for particle classification.

How Does Our Powder Sieve System Work?

Our powder sieve system is designed with advanced precision screening technology that may incorporate enhanced control of particle flow, optimized mesh configurations, and refined mechanical or pneumatic assistance to improve separation accuracy. Unlike conventional centrifugal sieves that rely solely on rotational force, our system might integrate multi-dimensional sieving actions or automated mesh cleaning to maintain consistent throughput and prevent screen blinding.

Comparing Precision in Particle Separation

Consistency of Force Application

Centrifugal sieves achieve precision through the uniform centrifugal force generated by spinning paddles, which is more consistent than the random motion in vibratory sieves. This consistency leads to better particle size separation and less product degradation. However, our powder sieve system may offer improved precision by combining centrifugal force with additional mechanisms that control particle distribution more evenly across the mesh surface, reducing variability in screening results.

Mesh and Screen Technology

The accuracy of any sieve system heavily depends on the mesh quality and its interaction with the material. Centrifugal sieves use nylon mesh screens clamped onto a rigid frame, which supports high-speed rotation and durability. Our system may employ advanced mesh materials or adaptive mesh tensioning technology to maintain optimal aperture size and prevent clogging, thereby enhancing precision and throughput.

Prevention of Screen Blinding

Screen blinding, where particles clog the mesh apertures, reduces sieving efficiency and precision. Centrifugal sieves often use brushes or other cleaning mechanisms to keep the mesh clear during operation. Our powder sieve system may incorporate more sophisticated self-cleaning features or airflow management to prevent blinding more effectively, ensuring continuous and precise particle separation.

Operational Advantages Influencing Precision

Throughput Capacity and Efficiency

Centrifugal sifters are known for their high capacity, processing larger volumes of material than vibratory sieves due to the effective centrifugal force. Our powder sieve system is likely designed to match or exceed this capacity while maintaining or improving precision. Enhanced feed control and optimized internal flow paths can reduce dead zones where material accumulates, thus improving screening consistency.

Dust Control and Hygiene

Centrifugal sieves provide a dust-free, hygienic environment, which is critical for pharmaceutical and food industries. Our system may enhance this aspect by offering completely sealed designs, silent operation without vibration, and quick mesh change capabilities, minimizing contamination risks and maintaining product integrity.

Maintenance and Reliability

Fewer moving parts in centrifugal sieves translate to lower maintenance needs and higher reliability. Our powder sieve system may further reduce maintenance through modular design, easy access for cleaning, and durable components that resist wear and tear, contributing to sustained precision over time.

Noise and Vibration Levels

Centrifugal sieves operate quietly compared to vibratory sieves, reducing noise pollution in the workplace. Our system might improve on this by employing vibration isolation techniques and quieter motors or drives, creating a more comfortable and controlled environment that indirectly supports precision by minimizing mechanical disturbances.

Application Suitability and Material Considerations

Handling Fragile and High-Precision Powders

Centrifugal sieves are less likely to cause product degradation because they generate less stress on particles than vibratory sieves. Our powder sieve system may be specifically engineered to handle delicate powders by controlling shear forces and avoiding particle breakage, thus preserving material quality and ensuring precise size classification.

Versatility Across Industries

While centrifugal sieves are widely used in pharmaceuticals, chemicals, and food industries, our system might offer broader adaptability to different powder types, moisture levels, and particle shapes. This versatility can translate into more precise sieving outcomes tailored to specific industrial needs.

Summary of Comparative Features

| Feature | Centrifugal Sieve | Our Powder Sieve System |

| Force Application | Uniform centrifugal force | Enhanced centrifugal + controlled flow |

| Mesh Technology | Nylon mesh, rigid frame | Advanced mesh materials, adaptive tension |

| Screen Blinding Prevention | Brushes or manual cleaning | Automated self-cleaning, airflow control |

| Throughput Capacity | High volume processing | Equal or higher with optimized flow |

| Dust and Hygiene | Dust-free, hygienic design | Fully sealed, silent operation |

| Maintenance | Low due to fewer moving parts | Modular, easy access, durable components |

| Noise Level | Low noise operation | Further reduced noise and vibration |

| Product Integrity | Less product degradation | Controlled shear forces for fragile powders |

| Industry Versatility | Pharmaceuticals, chemicals, food | Broader material adaptability |

Conclusion

Our powder sieve system offers several design and operational enhancements that can provide more precision than traditional centrifugal sieves. By integrating advanced mesh technology, improved flow control, better screen cleaning mechanisms, and enhanced maintenance features, it achieves finer particle separation with less variability and product damage. While centrifugal sieves remain highly effective and reliable for many applications, our system's innovations position it as a superior choice for industries demanding the highest precision in powder sieving.

Related Questions and Answers

Q1: What industries benefit most from using centrifugal sieves?

A1: Centrifugal sieves are widely used in pharmaceuticals, chemical manufacturing, food processing, and nutraceutical industries due to their high accuracy and hygienic design.

Q2: How does centrifugal force improve sieving precision?

A2: Centrifugal force provides consistent and uniform acceleration of particles against the mesh, resulting in more accurate size separation compared to vibratory motion.

Q3: What causes screen blinding and how can it be prevented?

A3: Screen blinding occurs when particles clog mesh apertures; it can be prevented by using brushes, airflow management, or automated cleaning systems.

Q4: Can powder sieve systems handle fragile materials without damaging them?

A4: Yes, systems designed with controlled shear forces and gentle handling mechanisms can sieve fragile powders without causing degradation.

Q5: What maintenance advantages do centrifugal sieves have over other sieving methods?

A5: Centrifugal sieves have fewer moving parts, reducing the frequency and complexity of maintenance compared to vibratory sieves.

[1] https://www.hanningfield.com/centrifugal-sifter-advantages/

[2] https://www.palamaticprocess.com/en-us/blog/centrifugal-sieve-or-vibrating-sieve-which-one-to-choose

[3] https://sanyuantangcn.com/blog/difference-between-horizontal-centrifugal-sifter-and-vertical-centrifugal-sifter.html

[4] https://blog.praterindustries.com/sieving-techniques-industrial-sieves-vs.-rotary-sifters

[5] https://www.vibrosievingmachine.com/the-comparison-of-centrifugal-sifter-vibro-sifter-machine-and-linear-vibrating-screen/

[6] https://blog.wordvice.cn/common-transition-terms-used-in-academic-papers/

[7] https://www.palamaticprocess.com/bulk-handling-equipment/industrial-sieve

[8] https://www.youtube.com/watch?v=o5FWssCWFUo

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.