Content Menu

● Introduction

● What is Powder Coating Equipment?

>> How Does Powder Coating Work? (H2)

>>> Key Equipment Components (H3)

● Why Buy Powder Coating Equipment from a Trusted OEM Manufacturer? (H2)

>> Benefits of OEM Services (H3)

● Choosing the Right Powder Coating Equipment (H2)

>> Factors to Consider (H3)

● The Powder Coating Process Explained (H2)

>> Step 1: Surface Preparation (H3)

>> Step 2: Powder Application (H3)

>> Step 3: Curing (H3)

>> Step 4: Cooling and Inspection (H3)

● Advantages of Powder Coating Equipment for Your Business (H2)

● Why Choose a Chinese Manufacturer for Powder Coating Equipment? (H2)

● Frequently Asked Questions (H2)

● Conclusion

Introduction

If you are looking to buy powder coating equipment, whether as an OEM, wholesaler, or manufacturer, understanding the equipment, processes, and services available is crucial to making the right investment. As a leading Chinese powder coating equipment manufacturer, supplier, and OEM service provider, we cater to global brands by delivering high-quality, customizable powder coating solutions. This comprehensive guide will walk you through everything you need to know about buying powder coating equipment, from technology and processes to tips on choosing the right machinery for your business.

What is Powder Coating Equipment?

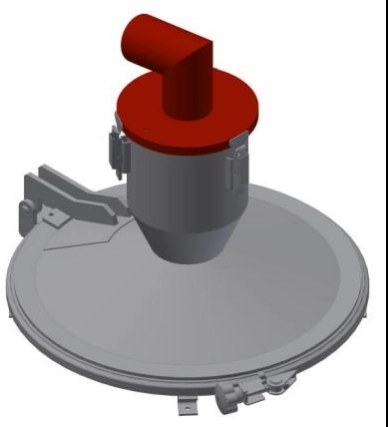

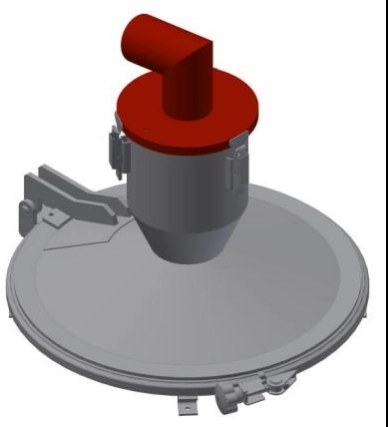

Powder coating equipment refers to the machinery and tools used to apply a dry powder coating onto a substrate, typically metal, to create a durable, protective, and decorative finish. The equipment includes electrostatic spray guns, fluidized bed systems, curing ovens, and conveyor systems, among others.

How Does Powder Coating Work? (H2)

Powder coating is an electrostatic process where dry powder particles are charged and sprayed onto grounded parts. The powder adheres to the surface and is then cured in an oven, melting and forming a solid, durable coating[1][2][4][7].

Key Equipment Components (H3)

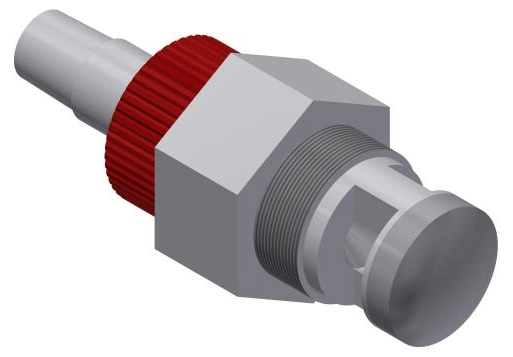

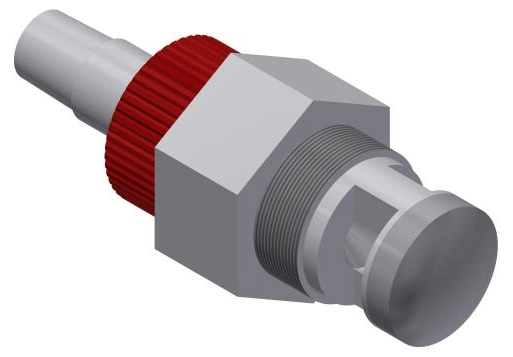

- Electrostatic Spray Guns: These guns charge the powder particles negatively, allowing them to be attracted to grounded parts.

- Fluidized Bed Systems: Used for dip-coating preheated parts in a fluidized powder bath.

- Curing Ovens: Heat the coated parts to melt and cure the powder, typically at temperatures around 400°F for 20-45 minutes.

- Conveyor Systems: Move parts through washing, coating, curing, and cooling stages efficiently.

Why Buy Powder Coating Equipment from a Trusted OEM Manufacturer? (H2)

Benefits of OEM Services (H3)

- Customization: OEM manufacturers can design equipment tailored to your specific production needs and product types.

- Quality Assurance: Working with experienced OEMs ensures high-quality machinery that meets international standards.

- Cost Efficiency: OEM partnerships often provide competitive pricing and flexible production volumes.

- Technical Support: Comprehensive after-sales service, including installation, training, and maintenance.

As a Chinese powder coating equipment manufacturer, we provide OEM services to international powder coating brands, wholesalers, and manufacturers, ensuring that your equipment matches your operational goals perfectly.

Choosing the Right Powder Coating Equipment (H2)

Factors to Consider (H3)

- Production Volume: Match equipment capacity with your expected throughput.

- Type of Coating Process: Electrostatic spraying, fluidized bed, or magnetic brush systems depending on your product.

- Curing Oven Size and Temperature Control: Ensure the oven fits your parts and can maintain consistent curing temperatures.

- Automation Level: Decide between manual, semi-automatic, or fully automated lines based on your budget and production needs.

- Powder Recovery System: Efficient powder reclaim systems reduce waste and improve cost-effectiveness.

The Powder Coating Process Explained (H2)

Understanding the process helps in selecting the right equipment and optimizing production.

Step 1: Surface Preparation (H3)

Blasting and pretreatment remove contaminants and create a surface profile for better powder adhesion. This includes degreasing, cleaning, etching, and phosphating[4][5].

Step 2: Powder Application (H3)

Electrostatic guns spray charged powder onto grounded parts, ensuring even coverage. Fluidized bed dipping is used for preheated parts for thicker coatings[1][2][5].

Step 3: Curing (H3)

Coated parts enter curing ovens where powder melts and crosslinks, forming a hard, durable finish. Typical curing is at 400°F for 20-45 minutes depending on part size[1][5].

Step 4: Cooling and Inspection (H3)

After curing, parts cool down and undergo quality control checks before packaging and shipment[5].

Advantages of Powder Coating Equipment for Your Business (H2)

- Durability: Powder coatings provide superior protection against corrosion, chemicals, and weather.

- Environmental Friendliness: Powder coating produces less waste and uses no solvents.

- Cost-Effectiveness: Efficient powder usage and fast curing reduce operational costs.

- Versatility: Suitable for various industries including automotive, heavy machinery, furniture, and electronics[9][10].

Why Choose a Chinese Manufacturer for Powder Coating Equipment? (H2)

China is a global leader in manufacturing powder coating equipment, offering:

- Advanced Technology: Modern production lines with high precision and automation.

- OEM Expertise: Years of experience serving international brands with customized solutions.

- Competitive Pricing: Cost advantages without compromising quality.

- Comprehensive Service: From design, production, installation to after-sales support.

- Strong Supply Chain: Efficient logistics and component sourcing ensure timely delivery[6][8].

Frequently Asked Questions (H2)

1. What types of powder coating equipment can I buy?

You can buy electrostatic spray guns, fluidized bed systems, curing ovens, conveyor systems, and powder recovery units.

2. How do I choose the right powder coating equipment for my business?

Consider your production volume, coating process type, automation needs, and budget.

3. What are the benefits of OEM powder coating equipment?

OEM equipment offers customization, better quality, cost savings, and dedicated technical support.

4. How long does the powder coating process take?

Typically, curing takes 20-45 minutes at around 400°F, plus time for surface preparation and cooling.

5. Can powder coating equipment be used for different industries?

Yes, powder coating is versatile and used in automotive, heavy machinery, furniture, electronics, and more.

Conclusion

Buying powder coating equipment is a strategic investment that can significantly enhance your manufacturing capabilities. Partnering with a reliable Chinese OEM manufacturer ensures you get high-quality, customizable equipment designed to meet your specific needs. Whether you are a brand owner, wholesaler, or manufacturer, understanding the powder coating process and equipment options will empower you to make informed decisions that drive your business forward.

[1] https://www.tiger-coatings.com/us-en/blog/powder-coating-process

[2] https://productionsystems-usa.com/powder-coating-process-for-the-manufacturing-industry/

[3] https://www.powdercoatedtough.com/News/ID/5278/Formulators-ForumHow-Are-Powder-Coatings-Made

[4] https://www.nordson.com/en/about-us/newsroom/industrial-coating-systems-news/complete-guide-to-powder-coating

[5] https://www.youtube.com/watch?v=hf9CBPEuEmg

[6] https://digital.bnpmedia.com/publication/?i=515645&p=43&pp=1&view=issueViewer

[7] https://metaltech.us/blog/powder-coating-101-how-does-it-work/

[8] https://kjc.tust.edu.cn/docs/20181012095635354040.xlsx

[9] https://oem.sherwin-williams.com/ap/chi/heavyequipment/

[10] https://www.wagner-group.com/cn/%E5%B7%A5%E4%B8%9A/%E4%BA%A7%E5%93%81/%E7%B2%89%E6%9C%AB%E5%96%B7%E6%B6%82/

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.