Content Menu

● Common Powder Sieve Issues and Their Causes

>> Mechanical and Operational Problems

>>> Insufficient Vibration or Throughput

>>> Overloaded or Clogged Sieve Mesh

>>> Faulty Feed Mechanism

>> Material-Related Issues

>>> Powder Moisture and Agglomeration

>>> Particle Size Distribution and Shape

>> Environmental and Safety Considerations

● Specific Troubleshooting Cases with Solutions

>> Problem: Sieve Throughput Is Too Low

>>> Potential Causes

>>> Recommended Solutions

>> Problem: Powder Clumps or Bridges in Hopper

>>> Potential Causes

>>> Recommended Solutions

>> Problem: Mesh Damage or Premature Wear

>>> Potential Causes

>>> Recommended Solutions

>> Problem: Excessive Noise During Sieve Operation

>>> Potential Causes

>>> Recommended Solutions

>> Problem: Powder Contamination or Cross-Contamination

>>> Potential Causes

>>> Recommended Solutions

● Frequently Asked Questions

Powder sieving is a crucial process in numerous industries such as pharmaceuticals, food production, chemicals, and powder coating. Despite its importance, powder sieving operations often encounter various challenges that can impact production efficiency, product quality, and operational costs. Understanding common problems and their solutions can significantly improve sieve performance and reduce downtime. This comprehensive article explores typical powder sieve troubleshooting issues, grouped by categories with practical solutions, and concludes with a Q&A section for further guidance.

Common Powder Sieve Issues and Their Causes

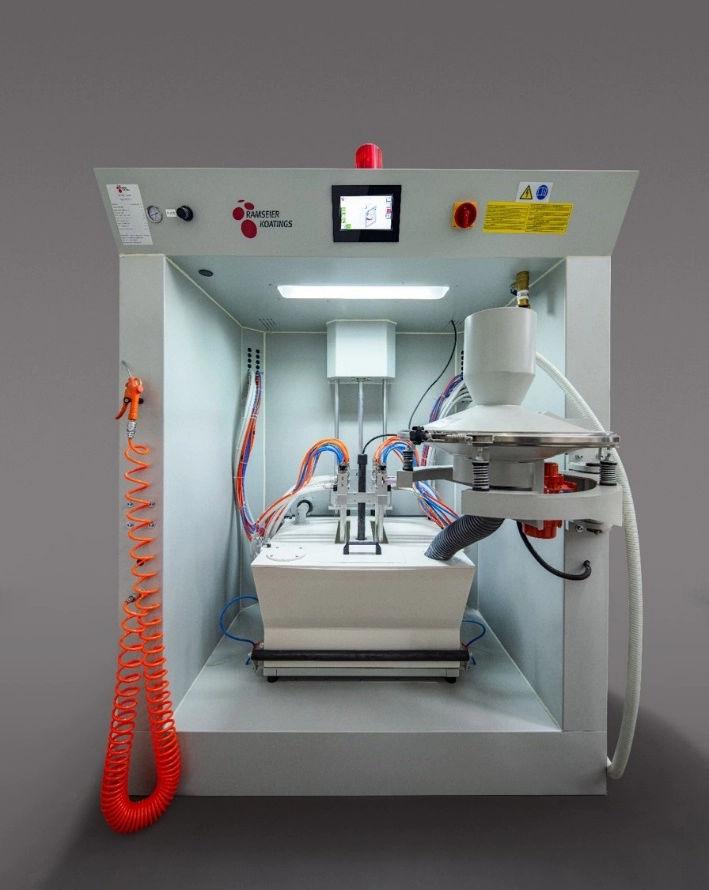

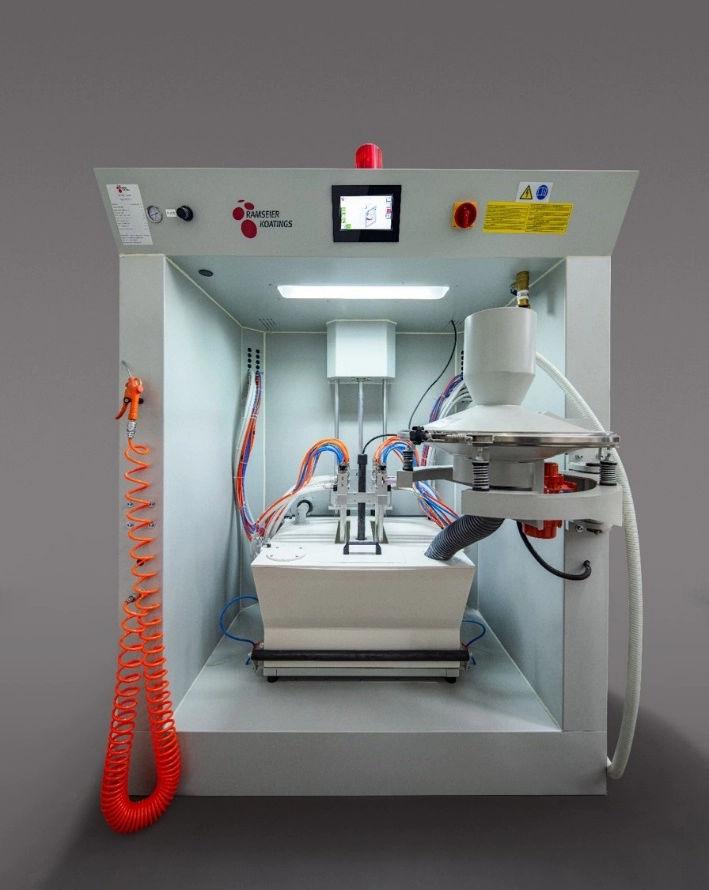

Powder sieves, whether vibrating sifters, rotary sieves, or ultrasonic sifters, can suffer from mechanical, material-related, and operational problems. These problems generally arise due to factors such as powder characteristics, equipment wear, improper settings, or environmental conditions.

Mechanical and Operational Problems

Insufficient Vibration or Throughput

One of the most frequent mechanical issues is insufficient vibration or low throughput, which leads to clogging or poor sieving efficiency. This can occur when the vibration motor is malfunctioning, the amplitude is set too low, or the sieve frame is inadequately supported.

- Causes:

- Motor not running or running erratically.

- Improper amplitude or vibration frequency settings.

- Loose connections or worn parts.

- Inadequate sieve support causing damping.

- Solutions:

- Inspect and repair or replace the vibration motor.

- Adjust amplitude and frequency according to the manufacturer's specifications to optimize powder flow.

- Tighten all mechanical connections.

- Ensure the sieve support structure is rigid and does not absorb vibration energy.

- For clogged sieves, consider using ultrasonic vibration to improve sieving efficiency, particularly for fine powders.

Overloaded or Clogged Sieve Mesh

Powder particles may clog the mesh, especially if the particle size is near the mesh opening size or if powders agglomerate. This reduces throughput and can result in poor separation.

- Causes:

- Wrong mesh size selection for the product.

- Moisture in the powder leading to sticky clumps.

- Electrostatic charges causing powder to stick to the mesh.

- Solutions:

- Review and select an appropriate mesh size based on powder particle size distribution.

- Control powder moisture content; use drying or dehumidification if necessary.

- Use anti-static measures such as grounding or ionizing air blowers.

- Clean the sieve regularly to prevent buildup.

Faulty Feed Mechanism

Inconsistent feeding or uneven powder distribution on the sieve surface can cause poor sieving performance.

- Causes:

- Incorrect feeder speed or settings.

- Blocked or damaged feed screws or hoppers.

- Powder bridging or rat-holing in feed containers.

- Solutions:

- Adjust feed rate to provide uniform and continuous flow.

- Regularly inspect and clean feeding components.

- Modify hopper design or use flow aids like vibrators or air fluidization to prevent bridging.

Material-Related Issues

Powder Moisture and Agglomeration

High moisture content causes powders to clump and adhere to sieve surfaces, leading to clogging and inconsistent particle separation.

- Solutions:

- Implement drying steps before sieving.

- Store powders in controlled humidity environments.

- Use flow conditioners or anti-caking agents if compatible.

Particle Size Distribution and Shape

Irregular particle shapes or a wide size range can hinder efficient screening, causing blockage or sieve damage.

- Solutions:

- Pre-process powders to reduce oversized particles.

- Employ multiple sieve stages with varying mesh sizes.

- Choose sieves with appropriate mesh and panel design for the powder characteristics.

Environmental and Safety Considerations

Dust generation and electrostatic hazards can present operational risks and affect sieve performance.

- Solutions:

- Use enclosed sieving systems with dust extraction.

- Implement grounding and anti-static devices.

- Train operators on safe handling of powders and equipment maintenance.

Specific Troubleshooting Cases with Solutions

Problem: Sieve Throughput Is Too Low

Potential Causes

- Insufficient vibration amplitude.

- Sieve mesh clogs due to fine or moist powders.

- Poor feed rate control.

Recommended Solutions

- Check vibration motor and adjust settings.

- Clean the mesh regularly or consider ultrasonic vibration.

- Ensure powder is dry and flowable.

- Adjust feed rate for optimal distribution.

Problem: Powder Clumps or Bridges in Hopper

Potential Causes

- High humidity or moisture absorption.

- Hopper design causing powder to stick or form arches.

Recommended Solutions

- Dry powder prior to sieving.

- Install vibration aids or air fluidization in feed hopper.

- Redesign hopper geometry to promote flow.

Problem: Mesh Damage or Premature Wear

Potential Causes

- Improper material selection for the mesh.

- Excessive vibration amplitude or frequency.

- Abrasive powders.

Recommended Solutions

- Use wear-resistant mesh materials.

- Adjust operational vibration settings.

- Schedule regular inspections and replacements.

Problem: Excessive Noise During Sieve Operation

Potential Causes

- Loose components.

- Worn vibration motors or bearings.

- Improper installation.

Recommended Solutions

- Tighten all fixtures.

- Replace worn parts.

- Verify installation alignment and isolation mounts.

Problem: Powder Contamination or Cross-Contamination

Potential Causes

- Powder buildup on frame or mesh.

- Residuals from previous batches.

- Inadequate cleaning procedures.

Recommended Solutions

- Implement standard cleaning protocols after each batch.

- Use easy-to-clean sieve designs.

- Validate cleaning effectiveness regularly.

Frequently Asked Questions

1. What is the best method to prevent sieve clogging?

Ensure proper mesh size selection, control powder moisture, clean the sieve regularly, and consider ultrasonic sieving for fine powders.

2. How often should a powder sieve be cleaned?

Cleaning frequency depends on powder type and usage but generally should be done after each batch or every shift for sticky or fine powders.

3. Can ultrasonic sieving improve powder throughput?

Yes, ultrasonic vibrations reduce mesh clogging and improve efficiency, particularly with fine or moist powders.

4. How do I know the right vibration amplitude for my sieve?

Follow the manufacturer's specifications and adjust based on powder behavior and throughput; too high may damage powders, too low reduces throughput.

5. What safety measures are necessary during powder sieving?

Use dust extraction, grounding to prevent static buildup, personal protective equipment, and ensure regular maintenance to prevent leaks and failures.

[1] https://www.gemapowdercoating.com/en/support/tips-tricks/sieve-problems

[2] https://blog.csdn.net/LuohenYJ/article/details/124871681

[3] https://www.azpowder.com/blog/troubleshooting-powder-application-issues

[4] https://www.sohu.com/a/537021423_121124350

[5] https://powderprocess.net/Checking_Powder_sieve.html

[6] https://blog.csdn.net/weixin_45386937/article/details/113763997

[7] https://www.linkedin.com/posts/powder-solutions-inc_keep-your-powder-sifters-running-smoothly-activity-7227661650877673472-jsHe

[8] https://patents.google.com/patent/CN118268248A/zh

[9] https://www.dahanmachine.com/blogs/Common-faults-and-solutions-of-ultrasonic-sifter.html

[10] https://www.163.com/opencourse/detail/video-QHIGRS7AV-YHIGRSCSB

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.