Content Menu

● Top Manufacturers of Powder Coating Equipment

>> Gema (Switzerland)

>> Nordson (USA)

>> Wagner (Germany)

>> Parker Ionics (USA)

>> Sames (France)

● Where to Purchase Powder Coating Equipment

>> Online Retailers

>> Specialty Distributors

>> Used Equipment Markets

● Key Factors When Choosing Equipment

>> Part Size and Production Volume

>> Facility Space and Workflow

>> Budget and Long-Term Needs

● Frequently Asked Questions

● Citations:

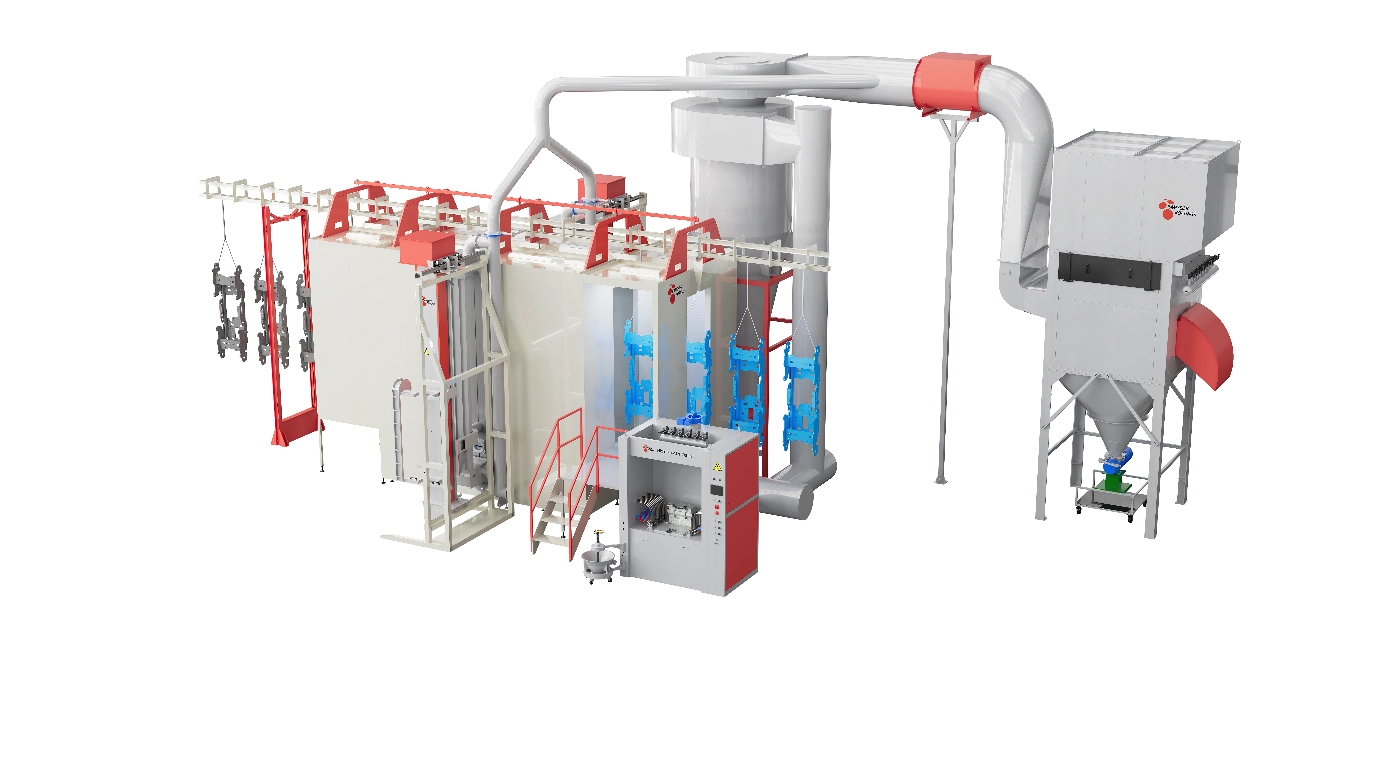

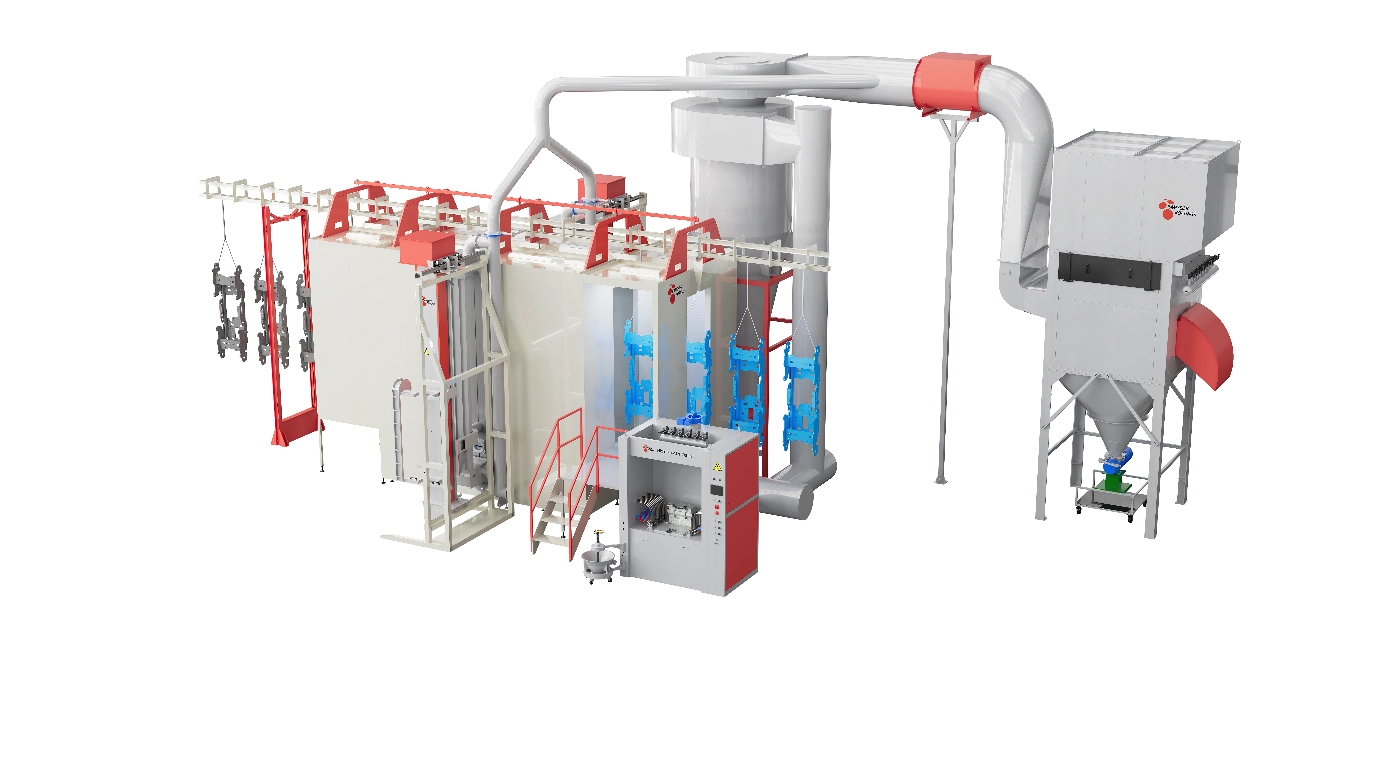

Powder coating has become a preferred finishing method for industries ranging from automotive to aerospace due to its durability, eco-friendliness, and cost efficiency. Whether you're setting up a new facility or upgrading existing systems, finding the right equipment is critical. This guide explores top manufacturers, purchasing channels, and key considerations to help you make informed decisions.

---

Top Manufacturers of Powder Coating Equipment

Gema (Switzerland)

A pioneer since 1962, Gema specializes in high-precision powder coating systems, including spray guns, booths, and digital control solutions. Their focus on innovation ensures efficient application and reduced waste, making them a go-to for industries requiring consistent quality.

Nordson (USA)

With decades of expertise, Nordson integrates smart technology into its equipment, offering automated systems that optimize workflows. Their customer support extends beyond sales, providing installation guidance and maintenance assistance.

Wagner (Germany)

Wagner combines ergonomic design with advanced electrostatic application tools. Their equipment suits both small workshops and large-scale operations, emphasizing user-friendly interfaces and energy efficiency.

Parker Ionics (USA)

Known for Pulse Power® technology, Parker Ionics delivers uniform coatings even on complex geometries. Their training workshops help operators master techniques for maximizing equipment performance.

Sames (France)

Sames excels in automated solutions for high-volume production, offering customizable systems that adapt to diverse part sizes and materials.

---

Where to Purchase Powder Coating Equipment

Online Retailers

- Eastwood: Provides hobbyist-friendly kits with a range of colors and accessories.

- Powder Buy The Pound: Offers same-day shipping for powders, guns, and replacement parts.

- Columbia Coatings: Sells turn-key systems tailored for small shops and DIY enthusiasts.

Specialty Distributors

- Reliant Finishing Systems: Guides buyers through equipment selection based on part size, throughput, and facility layout.

- EPTEK Coatings: Delivers industrial-grade ovens and spray booths with modular configurations.

Used Equipment Markets

- Buy Rite Finishing and Surplus Coatings: Supply refurbished systems at lower costs, ideal for startups or budget-conscious buyers.

- Powder-X Coating Systems: Offers hands-on training alongside pre-owned equipment purchases.

---

Key Factors When Choosing Equipment

Part Size and Production Volume

Measure the largest item you'll coat regularly. A booth should provide 2–3 feet of clearance around the part for operator mobility[3]. Ovens can be slightly smaller but must accommodate racks without overcrowding.

Facility Space and Workflow

Map your shop layout to ensure smooth movement between pretreatment, coating, and curing zones. Overhead conveyors or batch systems may optimize floor space.

Budget and Long-Term Needs

New systems from manufacturers like Nordson or Gema guarantee warranties and tech support. For limited budgets, certified refurbished equipment balances cost and reliability.

---

Frequently Asked Questions

1. How do I determine the right booth size?

Base dimensions on your largest part plus 2–3 feet of clearance. For example, a 4x5x6 ft part requires an 8x10x8 ft booth[3].

2. Is pre-treatment necessary before powder coating?

Yes. Blasting or washing removes contaminants. Dedicated blast/wash booths ensure proper adhesion[3].

3. Can I coat irregularly shaped parts?

Parker Ionics' electrostatic guns overcome Faraday cage effects, evenly coating recessed areas[4].

4. What's the average cost of a starter system?

Basic kits begin at $2,000, while industrial setups exceed $50,000. Used systems reduce upfront costs by 30–50%[8].

5. How do I maintain powder coating equipment?

Regularly clean guns and filters. Attend manufacturer workshops (e.g., Parker Ionics) to learn troubleshooting[2].

---

Citations:

[1] https://www.eastwood.com/powder-coating.html

[2] https://www.parkerionics.com/powder-coating-equipment.html

[3] https://reliantfinishingsystems.com/choosing-your-powder-coating-equipment/

[4] https://tifuls.com/top-10-powder-coating-line-manufacturers/

[5] https://www.eptexcoatings.com/powder_coating_packages/

[6] https://powderbuythepound.com

[7] https://www.columbiacoatings.com/products/equipment/turn-key-powder-system

[8] https://www.powdercoatingonline.com/powder-coating-used-equipment/

[9] https://www.wagner-group.com/us/industry/products/powder-coating/applying/

[10] https://powderx.com

[11] https://www.reddit.com/r/Powdercoating/comments/1d1iyle/whats_your_favorite_brand_of_powder/

[12] https://www.armaturecoil.com/blog/the-guide-for-buying-a-powder-coating-oven/

[13] https://ipco.com/industries/powder-coating/

[14] https://reliantfinishingsystems.com

[15] https://www.prismaticpowders.com

[16] https://www.thermalspray.com/selecting-powder-coating-equipment-an-essential-guide/

[17] https://www.creativecoatingsolutions.com/powder-coating-equipment-and-supplies.htm

[18] https://www.nordson.com/en/divisions/industrial-coating-systems/application-solutions/powder-coating

[19] https://www.ltcoatingline.com/resources/a-beginner-s-guide-to-powder-coating-equipment-systems-66b1aa3fe8e17.html

[20] https://thepowdercoatstore.com

---

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.