Content Menu

● Understanding Powder Coating

>> What is Powder Coating?

>> Benefits of Powder Coating

● The Swinger Powder Coating System

>> Features of the Swinger System

>> Why Quality Matters

● Calculating ROI for the Swinger Powder Coating System

>> Initial Investment

>> Long-Term Savings

>> Break-Even Analysis

● Case Studies: Success Stories with the Swinger System

>> Automotive Industry

>> Furniture Manufacturing

● Challenges and Considerations

>> Initial Costs vs. Long-Term Benefits

>> Training and Transition

● Conclusion

>> Frequently Asked Questions

In the competitive landscape of manufacturing and finishing, the choice of coating systems can significantly impact both the quality of the final product and the overall profitability of a business. Among the various options available, the Swinger Powder Coating System stands out as a premium choice that promises not only superior results but also a substantial return on investment (ROI). This article delves into the reasons why investing in a high-quality powder coating system like the Swinger can pay off in the long run.

Understanding Powder Coating

What is Powder Coating?

Powder coating is a finishing process that involves applying a dry powder to a surface, which is then cured under heat to form a durable, protective layer. Unlike traditional liquid paints, powder coatings do not require solvents, making them more environmentally friendly and efficient. The process is widely used in various industries, including automotive, furniture, and appliances, due to its ability to provide a tough, attractive finish.

Benefits of Powder Coating

The advantages of powder coating over conventional painting methods are numerous. These include:

- Durability: Powder coatings are known for their resistance to chipping, scratching, and fading, making them ideal for high-traffic and outdoor applications.

- Environmental Impact: With no volatile organic compounds (VOCs), powder coating is a greener option that complies with stringent environmental regulations.

- Cost-Effectiveness: Although the initial investment may be higher, the long-term savings in maintenance and replacement costs can be significant.

The Swinger Powder Coating System

Features of the Swinger System

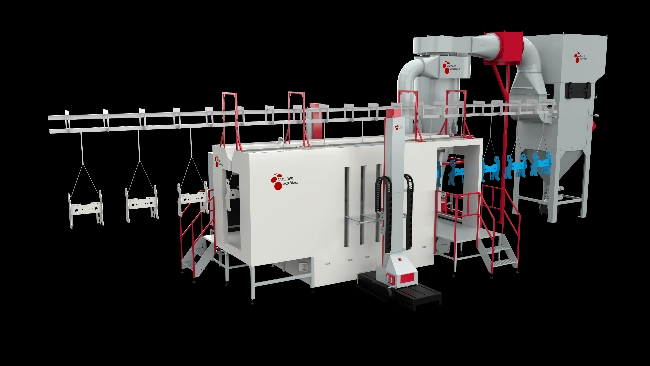

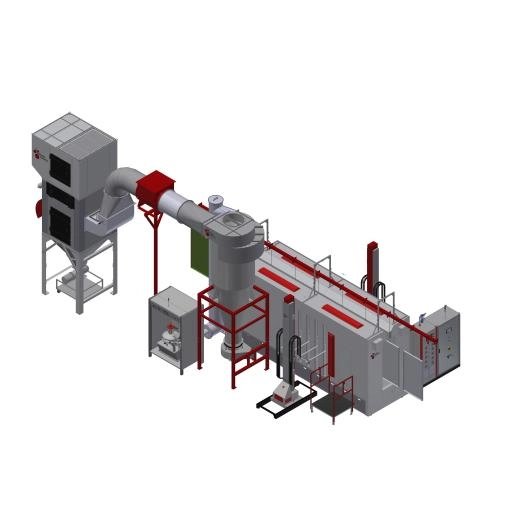

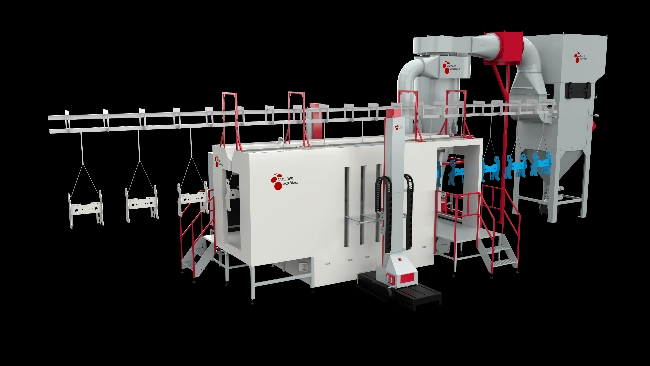

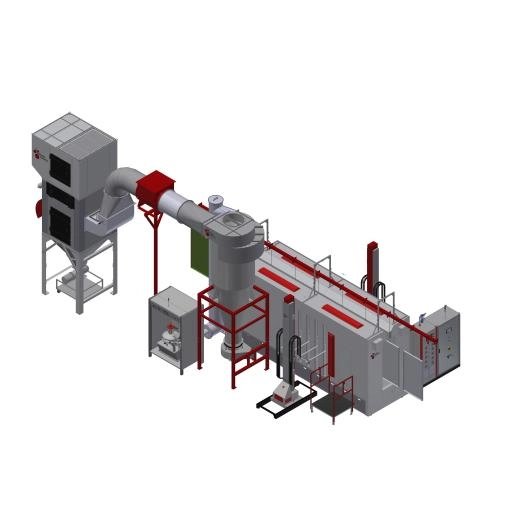

The Swinger Powder Coating System is designed with advanced technology that enhances efficiency and quality. Key features include:

- Automated Processes: The system incorporates automation to streamline operations, reducing labor costs and minimizing human error.

- Versatile Application: It can handle a wide range of materials and shapes, making it suitable for various industries.

- Energy Efficiency: The Swinger system is engineered to consume less energy during the curing process, leading to lower operational costs.

Why Quality Matters

Investing in a high-quality powder coating system like the Swinger is crucial for several reasons:

- Consistent Quality: High-quality systems ensure uniform application and curing, resulting in a consistent finish that meets customer expectations.

- Reduced Waste: Quality systems minimize overspray and material waste, contributing to a more sustainable operation.

- Enhanced Reputation: Delivering superior products enhances a company's reputation, leading to increased customer loyalty and repeat business.

Calculating ROI for the Swinger Powder Coating System

Initial Investment

The initial cost of acquiring a Swinger Powder Coating System can be significant. However, it is essential to view this as a long-term investment rather than a short-term expense. Factors to consider include:

- Purchase Price: The upfront cost of the system, including installation and training.

- Operational Costs: Ongoing expenses such as energy consumption, maintenance, and labor.

Long-Term Savings

The ROI from investing in a Swinger system can be calculated by considering the long-term savings it offers:

- Reduced Labor Costs: Automation reduces the need for manual labor, allowing companies to allocate resources more efficiently.

- Lower Material Costs: The precision of the Swinger system leads to less waste and lower material costs over time.

- Increased Production Capacity: With faster curing times and efficient processes, businesses can increase their output, leading to higher revenue.

Break-Even Analysis

To determine when the investment will pay off, businesses can conduct a break-even analysis. This involves calculating the point at which the savings from using the Swinger system equal the initial investment. Factors to include in this analysis are:

- Increased Sales Volume: The potential for increased sales due to improved product quality and customer satisfaction.

- Cost Savings: The cumulative savings from reduced labor and material costs over time.

Case Studies: Success Stories with the Swinger System

Automotive Industry

In the automotive sector, a manufacturer that switched to the Swinger Powder Coating System reported a 30% increase in production efficiency. The automated processes allowed for faster turnaround times, and the durable finish improved customer satisfaction, leading to a 15% increase in sales.

Furniture Manufacturing

A furniture manufacturer that adopted the Swinger system experienced a significant reduction in defects and returns. The consistent quality of the powder coating led to a 20% decrease in warranty claims, translating to substantial cost savings and enhanced brand reputation.

Challenges and Considerations

Initial Costs vs. Long-Term Benefits

While the initial investment in a Swinger Powder Coating System may be daunting, it is essential to weigh this against the long-term benefits. Companies must consider their production volume, the quality of their current finishes, and the potential for growth when making this decision.

Training and Transition

Transitioning to a new system requires proper training for staff to ensure they can operate the equipment effectively. Investing in training programs can help mitigate the learning curve and maximize the benefits of the new system.

Conclusion

Investing in a high-quality powder coating system like the Swinger is a strategic decision that can yield significant returns over time. By enhancing product quality, reducing operational costs, and increasing production efficiency, businesses can position themselves for long-term success in a competitive market. The initial investment may be substantial, but the potential for increased revenue and customer satisfaction makes it a worthwhile endeavor.

Frequently Asked Questions

1. What is the main advantage of using a powder coating system?

- The main advantage is its durability and resistance to chipping, scratching, and fading, making it ideal for various applications.

2. How does the Swinger Powder Coating System improve efficiency?

- The Swinger system incorporates automation and energy-efficient processes, reducing labor costs and operational expenses.

3. What industries benefit most from powder coating?

- Industries such as automotive, furniture, and appliances benefit significantly from powder coating due to its durability and aesthetic appeal.

4. How can I calculate the ROI of investing in a powder coating system?

- ROI can be calculated by considering initial investment costs, long-term savings from reduced labor and material costs, and increased production capacity.

5. What challenges might I face when transitioning to a new powder coating system?

- Challenges include the initial costs, the need for staff training, and the adjustment period as operations transition to the new system.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.