Content Menu

● Understanding Smart Control Systems

>> What Are Smart Control Systems?

>> Key Components of Smart Control Systems

● The Role of Smart Control Systems in Quality Assurance

>> Real-Time Monitoring and Control

>> Predictive Maintenance

>> Automated Inspection

● Benefits of Smart Control Systems in Coating Processes

>> Enhanced Efficiency

>> Improved Quality Control

>> Cost Reduction

>> Flexibility and Customization

● Challenges and Considerations

● Future Trends in Smart Control Systems for Coating Processes

● Conclusion

>> Frequently Asked Questions

In the modern manufacturing landscape, the demand for high-quality products has never been greater. Coating processes, which are critical in various industries such as automotive, aerospace, and electronics, require stringent quality assurance measures to ensure that the final products meet both aesthetic and functional standards. Smart control systems have emerged as a transformative solution, enhancing quality assurance in coating processes through automation, real-time monitoring, and advanced data analytics. This article explores how these systems improve quality assurance, the technologies involved, and the benefits they bring to the coating industry.

Understanding Smart Control Systems

What Are Smart Control Systems?

Smart control systems refer to automated systems that utilize advanced technologies, including the Internet of Things (IoT), artificial intelligence (AI), and machine learning, to monitor and control industrial processes. In the context of coating, these systems manage the application of coatings on various surfaces, ensuring optimal performance and quality. They integrate sensors, cameras, and data analytics to provide real-time feedback and adjustments, significantly enhancing the quality assurance process.

Key Components of Smart Control Systems

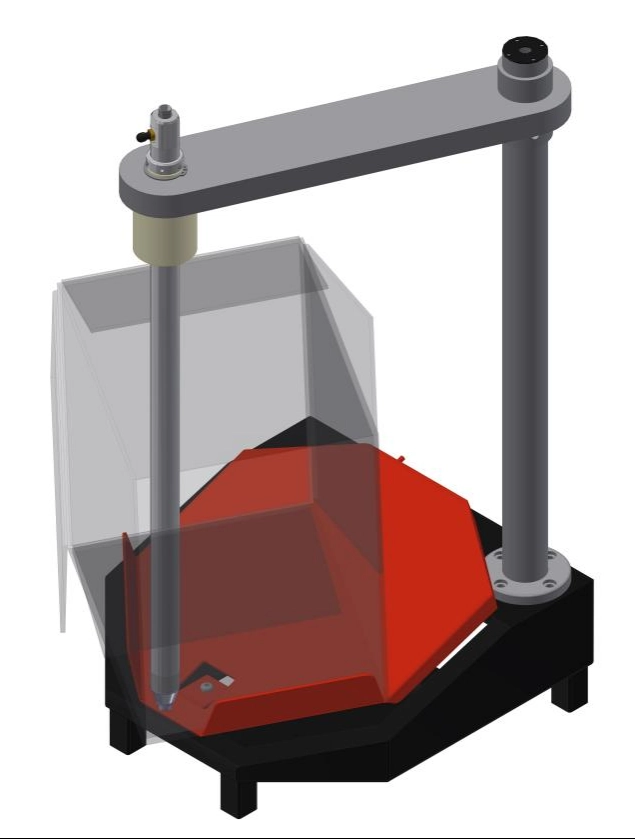

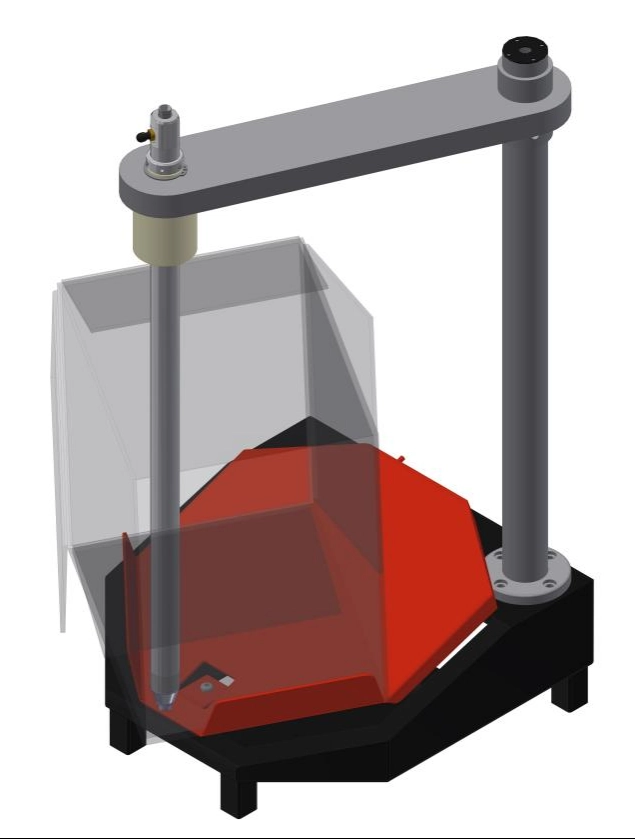

1. Sensors and Cameras: These devices collect data on various parameters such as coating thickness, temperature, and surface quality. They play a crucial role in detecting defects and ensuring that the coating process adheres to specified standards.

2. Data Analytics: Advanced algorithms analyze the data collected from sensors and cameras to identify patterns, predict potential issues, and suggest corrective actions. This predictive capability is essential for maintaining high-quality standards.

3. Automated Feedback Loops: Smart control systems can automatically adjust the coating process based on real-time data. For instance, if a sensor detects an uneven coating thickness, the system can modify the application parameters to correct the issue immediately.

The Role of Smart Control Systems in Quality Assurance

Real-Time Monitoring and Control

One of the most significant advantages of smart control systems is their ability to monitor coating processes in real-time. Traditional quality assurance methods often involve periodic inspections, which can lead to delays in identifying defects. In contrast, smart systems continuously analyze data, allowing for immediate detection of anomalies. This capability minimizes the risk of defective products reaching the market and reduces the need for costly rework.

Predictive Maintenance

Smart control systems leverage AI to predict equipment failures before they occur. By analyzing performance data, these systems can identify signs of wear and tear, enabling proactive maintenance. This predictive maintenance approach not only reduces downtime but also ensures that the coating equipment operates at optimal efficiency, further enhancing product quality.

Automated Inspection

Automated inspection systems, powered by machine learning algorithms, can identify defects that may be invisible to the human eye. These systems can detect issues such as uneven coating, bubbles, or contamination, ensuring that only high-quality products proceed through the production line. The integration of automated inspection significantly reduces the reliance on manual checks, which can be prone to human error.

Benefits of Smart Control Systems in Coating Processes

Enhanced Efficiency

Smart control systems streamline the coating process by automating various tasks, from material preparation to application and inspection. This automation leads to faster production times and reduced labor costs. Additionally, by minimizing human intervention, these systems decrease the likelihood of errors, further enhancing overall efficiency.

Improved Quality Control

With real-time monitoring and automated inspection, smart control systems significantly improve quality control in coating processes. They ensure that every product meets the required specifications, reducing the incidence of defects and enhancing customer satisfaction. Consistent quality translates into fewer customer complaints and a stronger reputation for reliability.

Cost Reduction

By reducing defects and minimizing rework, smart control systems contribute to significant cost savings. The automation of processes also leads to lower labor costs and reduced material waste. Furthermore, predictive maintenance helps avoid costly downtime, allowing manufacturers to operate more efficiently and profitably.

Flexibility and Customization

Smart control systems offer flexibility in adapting to different coating requirements. Manufacturers can easily adjust parameters to accommodate various materials, coating types, and production volumes. This adaptability is crucial in today's fast-paced manufacturing environment, where customization and quick turnaround times are often necessary.

Challenges and Considerations

While the benefits of smart control systems are substantial, there are challenges to consider. The initial investment in technology can be significant, and companies must ensure that their workforce is adequately trained to operate and maintain these systems. Additionally, integrating smart control systems into existing processes may require careful planning and execution to avoid disruptions.

Future Trends in Smart Control Systems for Coating Processes

As technology continues to evolve, the capabilities of smart control systems are expected to expand. Future trends may include:

1. Increased Use of AI and Machine Learning: As these technologies advance, they will enable even more sophisticated predictive analytics and automated decision-making processes.

2. Greater Integration with IoT: The continued growth of IoT will allow for more interconnected systems, providing manufacturers with comprehensive insights into their operations.

3. Sustainability Focus: Smart control systems will increasingly incorporate sustainability metrics, helping manufacturers reduce their environmental impact while maintaining quality.

4. Enhanced User Interfaces: Future systems will likely feature more intuitive user interfaces, making it easier for operators to interact with and manage the technology.

Conclusion

Smart control systems are revolutionizing quality assurance in coating processes by providing real-time monitoring, predictive maintenance, and automated inspection capabilities. These systems enhance efficiency, improve product quality, and reduce costs, making them an essential component of modern manufacturing. As technology continues to advance, the role of smart control systems in the coating industry will only become more significant, driving innovation and ensuring that manufacturers can meet the ever-increasing demands for quality and performance.

Frequently Asked Questions

1. What are smart control systems?

Smart control systems are automated systems that use advanced technologies like IoT and AI to monitor and control industrial processes, ensuring optimal performance and quality.

2. How do smart control systems improve quality assurance?

They provide real-time monitoring, predictive maintenance, and automated inspection, allowing for immediate detection and correction of defects.

3. What are the benefits of using smart control systems in coating processes?

Benefits include enhanced efficiency, improved quality control, cost reduction, and flexibility in adapting to different coating requirements.

4. What challenges are associated with implementing smart control systems?

Challenges include the initial investment cost, the need for workforce training, and the integration of new systems into existing processes.

5. What future trends can we expect in smart control systems?

Future trends may include increased use of AI, greater IoT integration, a focus on sustainability, and enhanced user interfaces.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.