Content Menu

● Understanding Intelligent Coating Data Systems

>> What Are Intelligent Coating Data Systems?

>> The Role of Coatings in Manufacturing

● The Driving Forces Behind Investment

>> 1. Enhanced Quality Control

>> 2. Increased Operational Efficiency

>> 3. Cost Reduction

>> 4. Data-Driven Decision Making

>> 5. Compliance and Regulatory Requirements

● The Technological Landscape

>> Integration with Industry 4.0

>> Machine Learning and Predictive Analytics

● Case Studies: Success Stories

>> Automotive Industry

>> Aerospace Sector

>> Electronics Manufacturing

● Future Implications

>> Sustainability and Environmental Impact

>> The Evolution of Coating Technologies

● Conclusion

>> Frequently Asked Questions

In the rapidly evolving landscape of manufacturing, the integration of advanced technologies has become a cornerstone for success. Among these technologies, intelligent coating data systems stand out as a transformative solution that enhances efficiency, quality, and competitiveness. This article explores the reasons why leading manufacturers are investing in these systems, the benefits they offer, and the future implications for the industry.

Understanding Intelligent Coating Data Systems

What Are Intelligent Coating Data Systems?

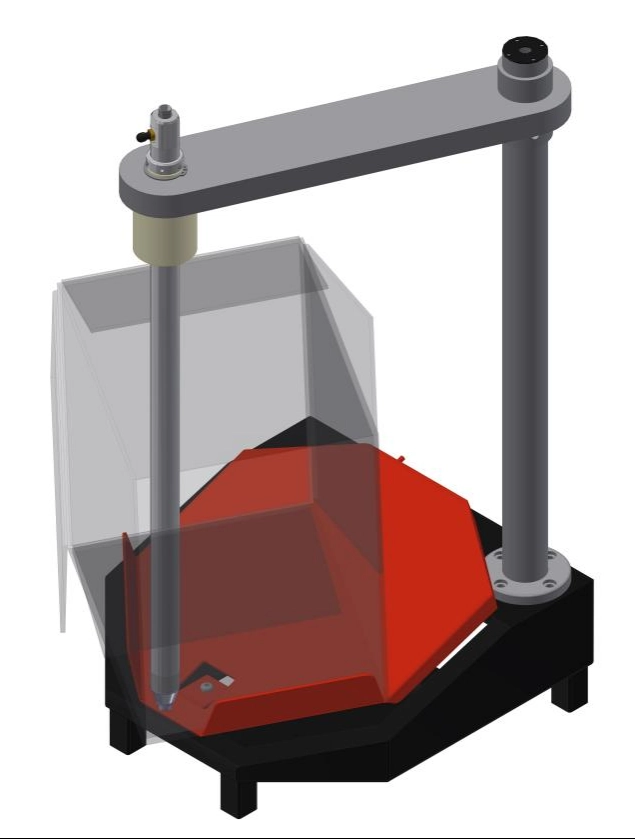

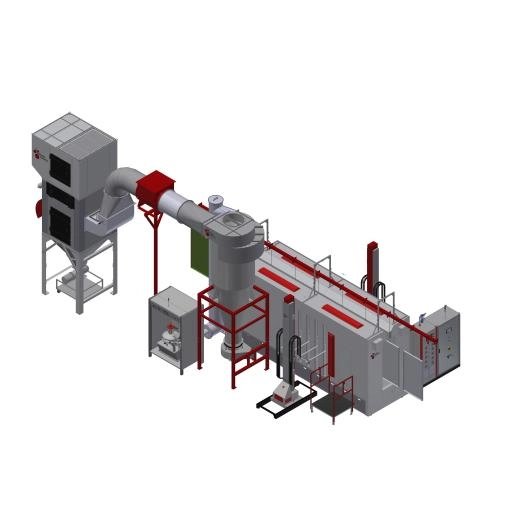

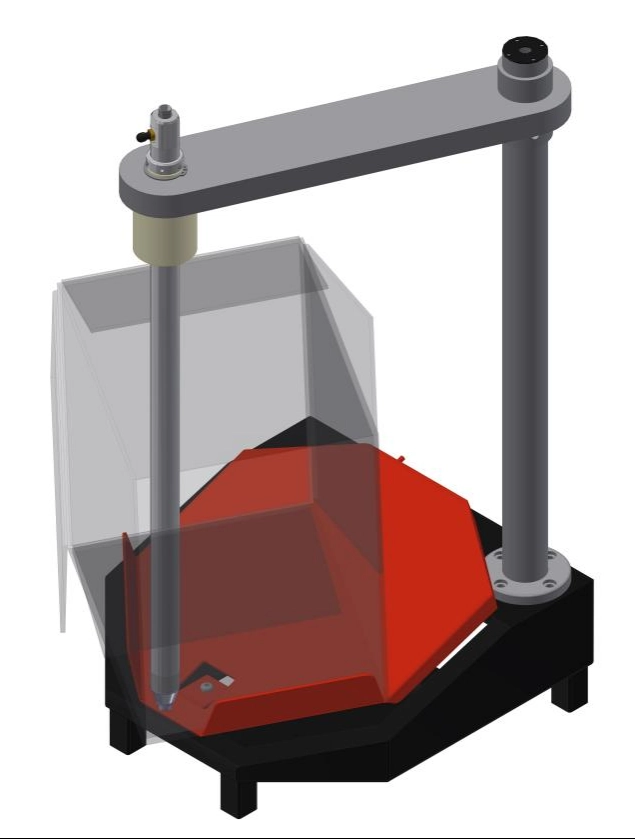

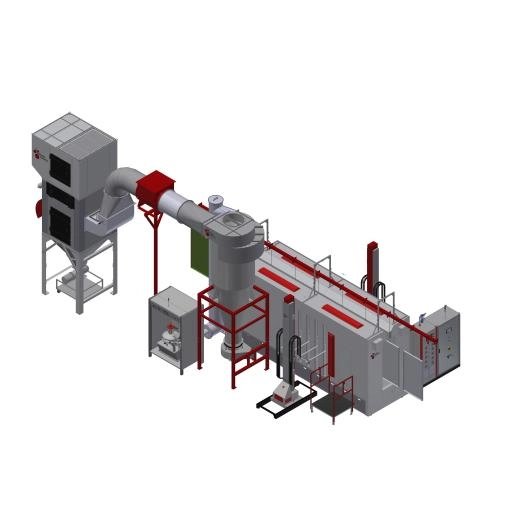

Intelligent coating data systems are sophisticated platforms that collect, analyze, and manage data related to the coating processes in manufacturing. These systems utilize advanced algorithms, machine learning, and real-time data analytics to optimize coating applications, ensuring that products meet stringent quality standards while minimizing waste and operational costs.

The Role of Coatings in Manufacturing

Coatings play a critical role in various manufacturing sectors, including automotive, aerospace, electronics, and consumer goods. They provide essential functions such as protection against corrosion, wear, and environmental factors, as well as enhancing aesthetic appeal. The quality of coatings directly impacts product performance and longevity, making it imperative for manufacturers to adopt precise and efficient coating processes.

The Driving Forces Behind Investment

1. Enhanced Quality Control

One of the primary reasons manufacturers invest in intelligent coating data systems is the significant improvement in quality control. These systems enable real-time monitoring of coating parameters, such as thickness, adhesion, and uniformity. By analyzing this data, manufacturers can quickly identify deviations from quality standards and make necessary adjustments, reducing the likelihood of defects and rework.

2. Increased Operational Efficiency

Intelligent coating data systems streamline the coating process by automating data collection and analysis. This automation reduces the time and labor required for manual inspections and data entry, allowing employees to focus on more strategic tasks. Additionally, these systems can optimize coating recipes and application techniques, leading to faster production cycles and reduced material waste.

3. Cost Reduction

Investing in intelligent coating data systems can lead to substantial cost savings. By minimizing defects and rework, manufacturers can lower their operational costs. Furthermore, the optimization of coating processes reduces material consumption and energy usage, contributing to a more sustainable manufacturing environment. Over time, these savings can significantly enhance a company's bottom line.

4. Data-Driven Decision Making

In today's data-centric world, the ability to make informed decisions based on accurate data is crucial. Intelligent coating data systems provide manufacturers with valuable insights into their coating processes, enabling them to make data-driven decisions. This capability allows for continuous improvement and innovation, as manufacturers can identify trends, assess performance, and implement changes based on empirical evidence.

5. Compliance and Regulatory Requirements

Manufacturers are often subject to stringent regulatory requirements regarding product quality and environmental impact. Intelligent coating data systems help ensure compliance by providing detailed records of coating processes and outcomes. This documentation is essential for audits and certifications, allowing manufacturers to demonstrate their commitment to quality and sustainability.

The Technological Landscape

Integration with Industry 4.0

The rise of Industry 4.0 has revolutionized manufacturing, and intelligent coating data systems are a key component of this transformation. These systems can be integrated with other smart manufacturing technologies, such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics. This integration enables manufacturers to create a connected ecosystem where data flows seamlessly between machines, processes, and decision-makers.

Machine Learning and Predictive Analytics

Machine learning algorithms play a vital role in intelligent coating data systems. By analyzing historical data, these algorithms can predict potential issues before they occur, allowing manufacturers to take proactive measures. Predictive analytics can also optimize maintenance schedules, reducing downtime and ensuring that coating equipment operates at peak efficiency.

Case Studies: Success Stories

Automotive Industry

In the automotive sector, leading manufacturers have adopted intelligent coating data systems to enhance the quality and durability of their vehicles. By implementing real-time monitoring and data analysis, these companies have reduced defects in paint applications, resulting in higher customer satisfaction and lower warranty claims.

Aerospace Sector

Aerospace manufacturers face unique challenges due to the stringent safety and performance requirements of their products. Intelligent coating data systems have enabled these companies to achieve precise control over coating applications, ensuring that components meet the highest standards of quality and reliability.

Electronics Manufacturing

In the electronics industry, the demand for miniaturization and increased functionality has led to the need for advanced coating solutions. Intelligent coating data systems allow manufacturers to optimize coatings for circuit boards and other components, improving performance while reducing the risk of failure.

Future Implications

Sustainability and Environmental Impact

As manufacturers increasingly focus on sustainability, intelligent coating data systems can play a crucial role in reducing environmental impact. By optimizing coating processes, manufacturers can minimize waste and energy consumption, contributing to a more sustainable future. Additionally, these systems can help identify eco-friendly coating materials and processes, aligning with global sustainability goals.

The Evolution of Coating Technologies

The future of coating technologies is likely to be shaped by advancements in intelligent data systems. As these systems become more sophisticated, manufacturers will be able to explore new coating materials and techniques that enhance performance and reduce costs. This evolution will drive innovation across various industries, leading to the development of smarter, more efficient products.

Conclusion

The investment in intelligent coating data systems is not just a trend; it is a strategic move that leading manufacturers are making to stay competitive in a rapidly changing market. By enhancing quality control, increasing operational efficiency, reducing costs, and enabling data-driven decision-making, these systems are transforming the manufacturing landscape. As technology continues to evolve, the role of intelligent coating data systems will only become more critical, paving the way for a more efficient, sustainable, and innovative future in manufacturing.

Frequently Asked Questions

1. What are the main benefits of intelligent coating data systems?

Intelligent coating data systems enhance quality control, increase operational efficiency, reduce costs, enable data-driven decision-making, and ensure compliance with regulatory requirements.

2. How do intelligent coating data systems integrate with Industry 4.0?

These systems can connect with other smart manufacturing technologies, such as IoT and AI, creating a seamless flow of data across machines and processes.

3. Can intelligent coating data systems help with sustainability?

Yes, they optimize coating processes to minimize waste and energy consumption, contributing to a more sustainable manufacturing environment.

4. What industries benefit the most from intelligent coating data systems?

Industries such as automotive, aerospace, and electronics have seen significant improvements in quality and efficiency through the adoption of these systems.

5. How do machine learning and predictive analytics enhance coating processes?

Machine learning algorithms analyze historical data to predict potential issues, allowing manufacturers to take proactive measures and optimize maintenance schedules.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.