Content Menu

● Understanding Reciprocators in Industrial Production

>> What Is a Reciprocator?

>> The Role of Reciprocators in High-Volume Manufacturing

● Critical Features of a Reciprocator Suitable for High-Volume Production

>> High-Speed Capability

>>> Consistent and Controlled Rapid Movement

>>> Minimizing Heat and Friction

>> Durability and Robust Construction

>>> Use of High-Quality Materials

>>> Impact-Resistant Design

>> Precision and Repeatability

>>> Accurate Stroke Control

>>> Maintaining Repeatable Motion

>> Ease of Integration and Automation Compatibility

>>> Modular Design for Versatility

>>> Advanced Control Systems

● Maintenance and Serviceability: Sustaining High-Volume Performance

>> Simplified Maintenance Procedures

>> Predictive Maintenance Features

>> Availability of Spare Parts

● Operational Considerations for Optimal Performance

>> Load Capacity and Force Output

>> Energy Efficiency

>> Noise and Vibration Management

● Case Study: Reciprocators in Packaging Industry

>> Challenges Addressed

>> Solutions Implemented

● How to Select the Right Reciprocator for Your High-Volume Production

>> Analyze Production Requirements

>> Evaluate Machine Specifications

>> Consider Vendor Support

>> Test Before Commitment

● Frequently Asked Questions (FAQ)

>> 1. What types of materials are best for reciprocators used in high-volume production?

>> 2. How important is stroke length adjustability in a reciprocator?

>> 3. Can reciprocators be integrated into fully automated production lines?

>> 4. What maintenance practices extend the life of a reciprocator?

>> 5. How does noise and vibration control impact reciprocator performance in high-volume settings?

● Conclusion

The demand for manufacturing efficiency and speed is greater than ever, especially in industries relying on reciprocating machinery. Whether in packaging, automotive, electronics, or pharmaceuticals, high-volume production lines require equipment that can operate reliably, consistently, and at a rapid pace. Reciprocators — machines that convert rotary motion into back-and-forth linear movement — play a crucial role in many of these settings. But not all reciprocators are created equal, and understanding what makes a reciprocator suitable for high-volume production is essential for manufacturers seeking to optimize their workflows.

This article explores the key factors that determine a reciprocator's suitability for high-volume production environments, highlighting important design features, material considerations, operational characteristics, and maintenance aspects.

Understanding Reciprocators in Industrial Production

What Is a Reciprocator?

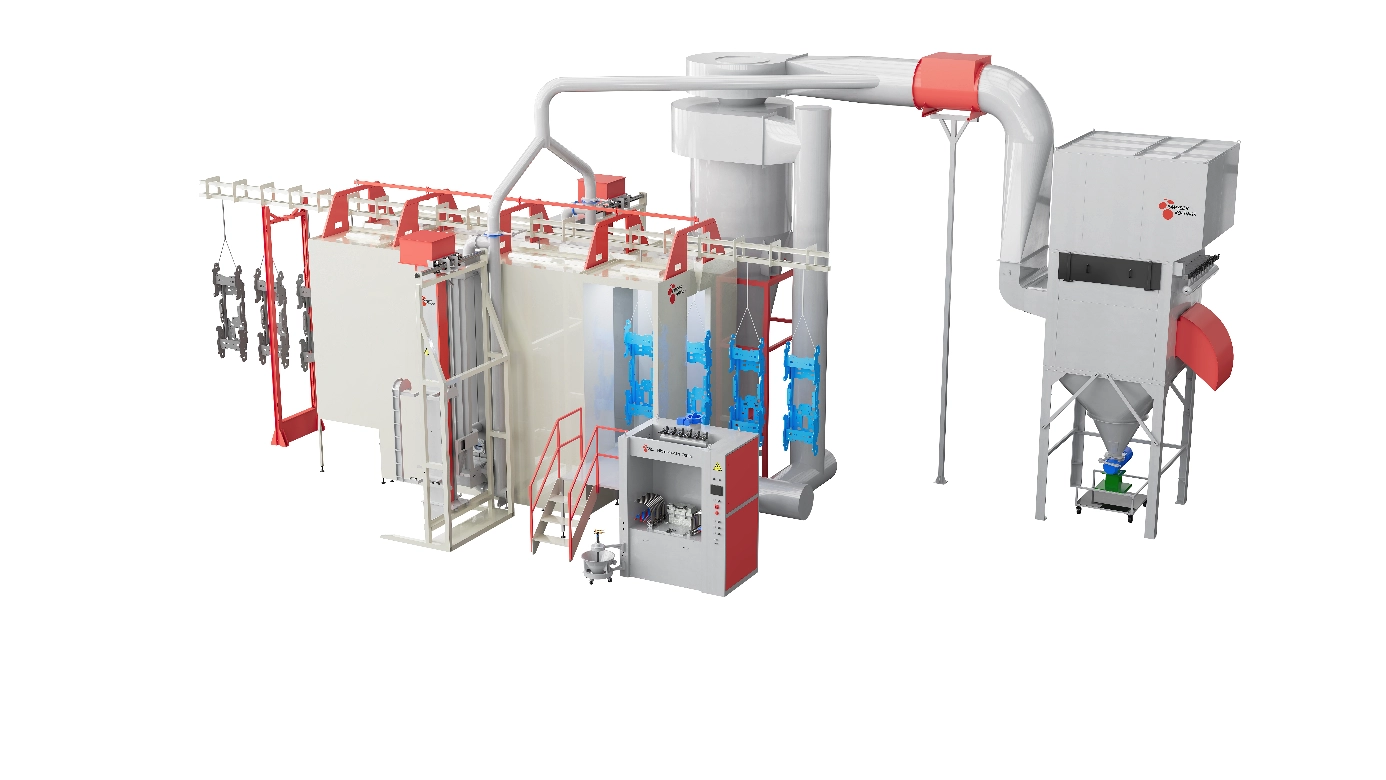

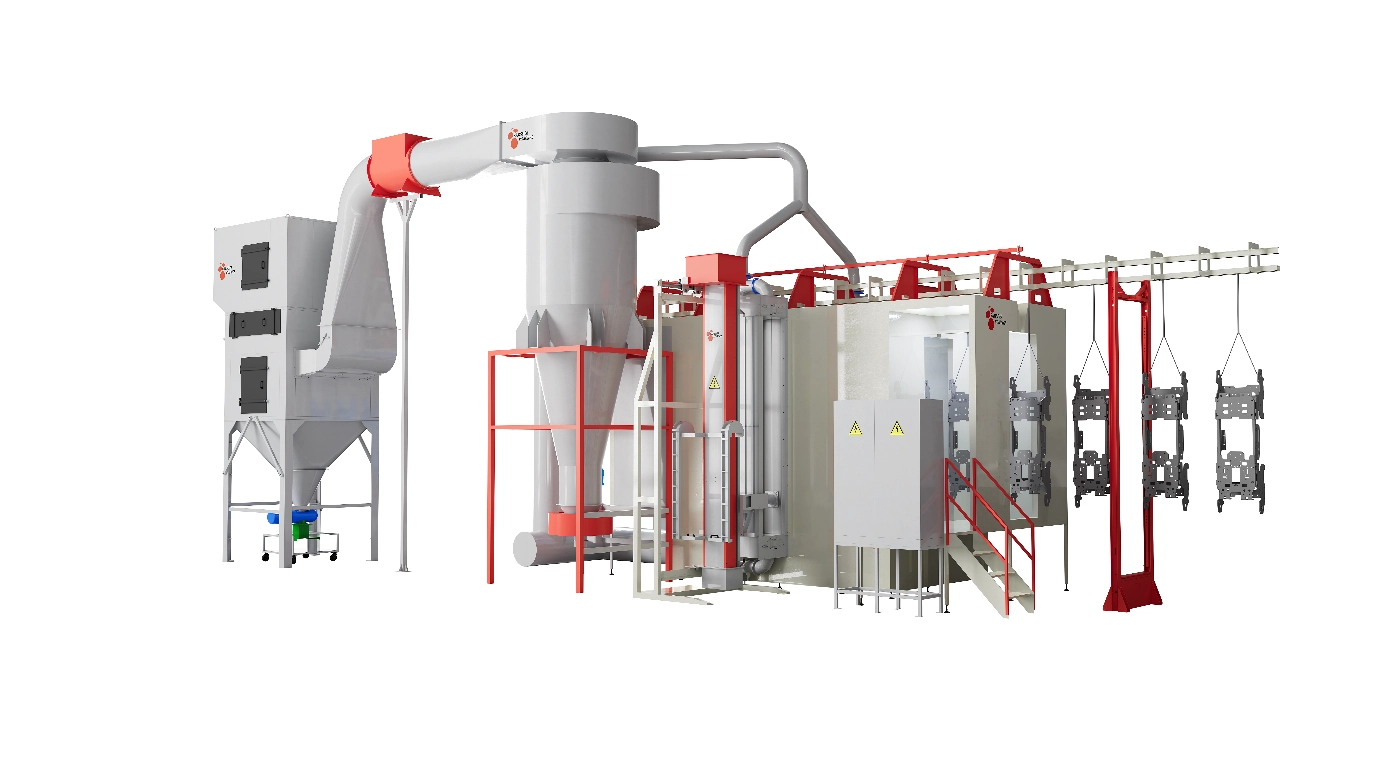

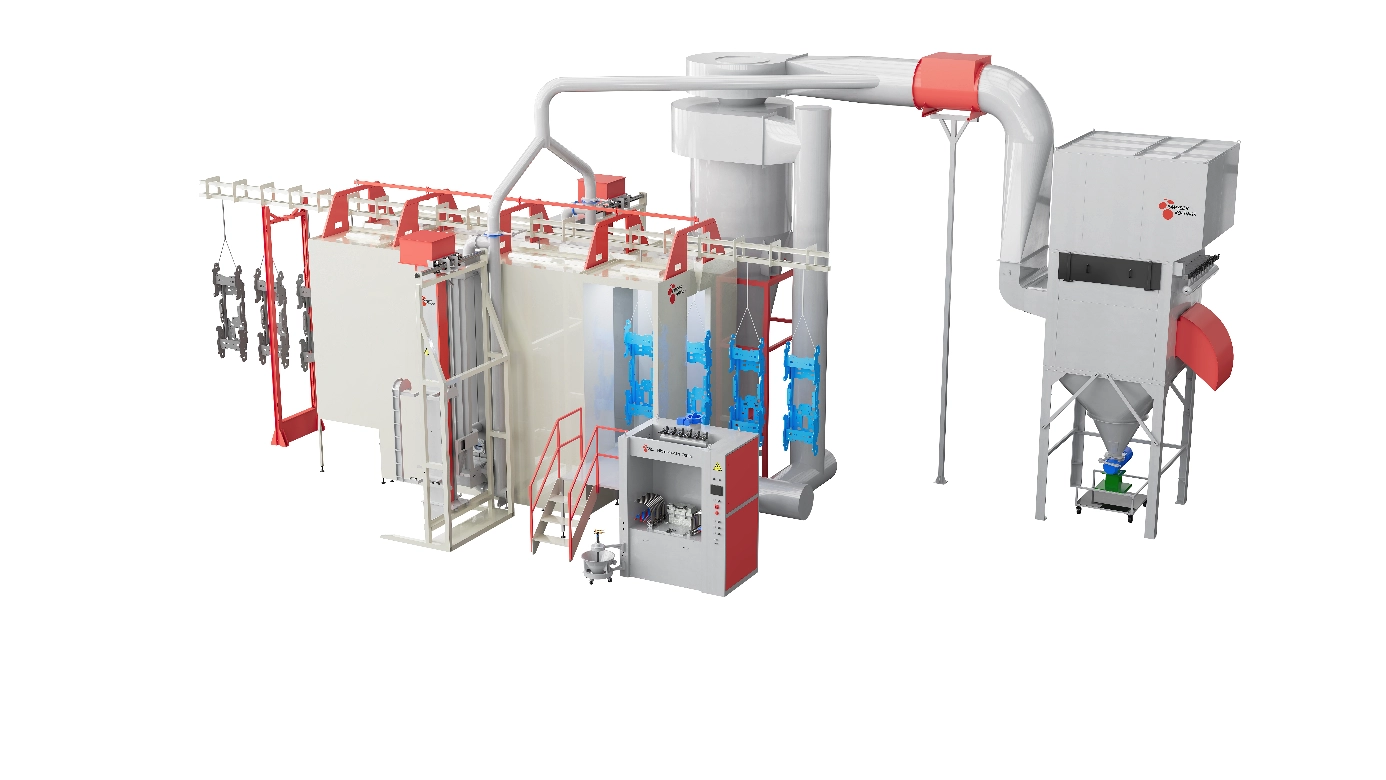

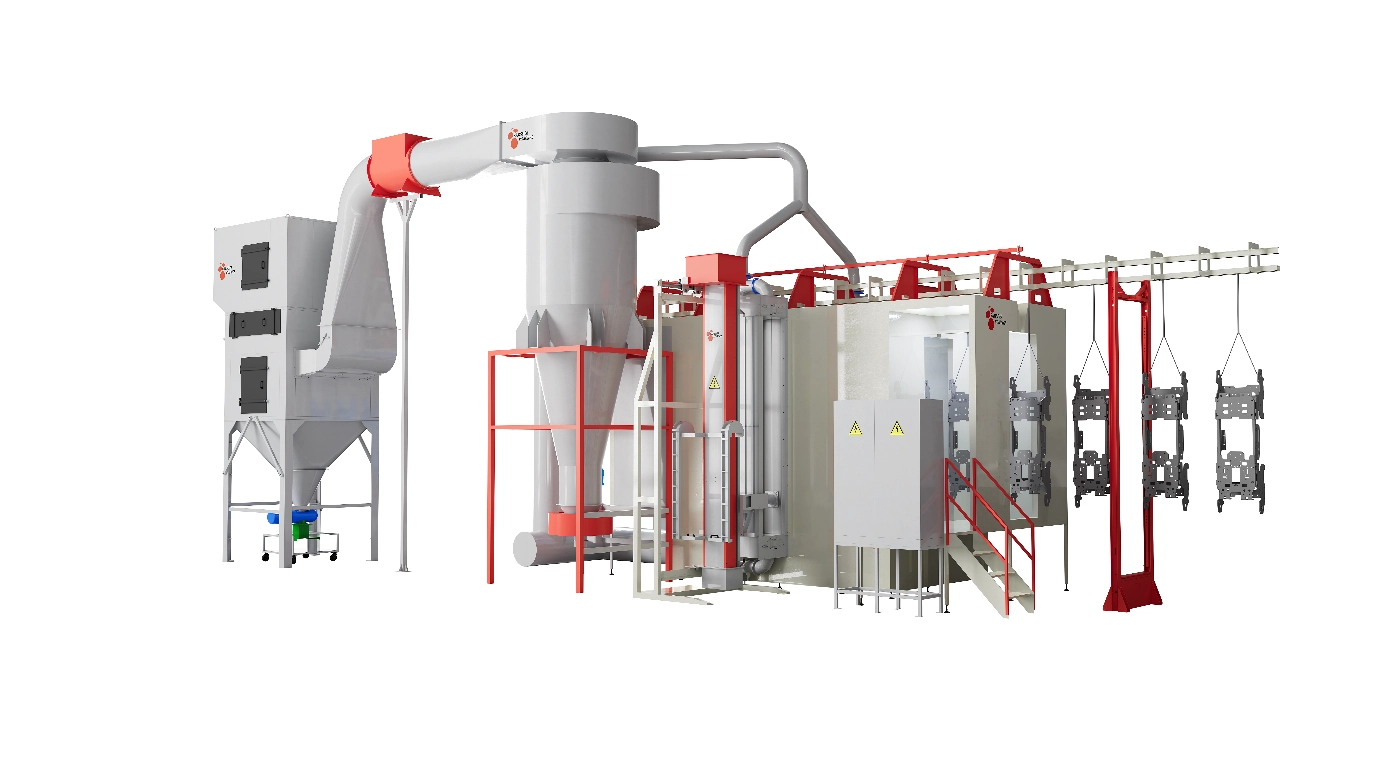

A reciprocator is a mechanical device designed to produce a repetitive linear movement—moving an object or tool back and forth in a straight line. This motion is fundamental for applications such as stapling, cutting, stamping, sealing, and feeding in various production processes. The efficiency of a reciprocator directly influences the speed and quality of these repetitive tasks.

The Role of Reciprocators in High-Volume Manufacturing

In high-volume production, the reciprocator must handle thousands—even millions—of cycles reliably without failure or significant performance drops. The continuous and rapid reciprocating action accelerates production rates, reduces downtime, and ensures product consistency. Choosing the right reciprocator for such environments can significantly impact overall operational costs and output quality.

Critical Features of a Reciprocator Suitable for High-Volume Production

High-Speed Capability

Consistent and Controlled Rapid Movement

To meet the demands of high-volume manufacturing, a reciprocator must operate at high speeds without compromising accuracy or causing wear and tear. High-speed capability enables the machine to perform more cycles per minute, directly impacting throughput.

Advanced reciprocators utilize precision components and balanced designs to minimize vibration and noise at high speeds, ensuring smooth and consistent operation.

Minimizing Heat and Friction

At high speeds, friction generates heat, which can degrade components and reduce operational lifespan. Suitable reciprocators incorporate materials with low friction coefficients and employ lubrication systems to maintain thermal stability and reduce wear.

Durability and Robust Construction

Use of High-Quality Materials

Materials used in constructing the reciprocator's moving parts must withstand repetitive stress, shocks, and environmental factors such as dust or moisture. Hardened steel, advanced alloys, and reinforced composites are common material choices that provide longevity.

Impact-Resistant Design

In high-volume applications, sudden impacts or pressure spikes during operation are common. A robust reciprocator design includes shock absorbers, vibration dampers, or flexible couplings to mitigate these forces and prevent damage or misalignment.

Precision and Repeatability

Accurate Stroke Control

Precision is critical in high-volume environments to ensure each cycle performs identically. Reciprocators with adjustable stroke lengths and high-resolution position sensors allow manufacturers to fine-tune operation parameters for optimal results.

Maintaining Repeatable Motion

Repeatability ensures the same motion parameters are applied every cycle, which is vital for product consistency. Precision bearings, guides, and feedback control systems help maintain repeatability throughout extensive production runs.

Ease of Integration and Automation Compatibility

Modular Design for Versatility

A reciprocator suited for mass production should integrate seamlessly with automated systems such as conveyors, robotic arms, and PLCs (Programmable Logic Controllers). Modular designs with standard interfaces enable easy customization and scalability.

Advanced Control Systems

Modern reciprocators are typically equipped with programmable controls that allow synchronization with other production line equipment. This automation compatibility enhances operational efficiency and reduces manual intervention.

Maintenance and Serviceability: Sustaining High-Volume Performance

Simplified Maintenance Procedures

High-volume production means equipment downtime leads to significant losses. Reciprocators designed for this environment feature components that are easy to access and replace, minimizing repair times.

Predictive Maintenance Features

Incorporating sensors that monitor wear, temperature, lubrication status, and vibration enables predictive maintenance. This reduces unexpected breakdowns by alerting operators before major issues arise.

Availability of Spare Parts

Manufacturers relying on reciprocators for high-volume tasks must consider the availability of replacement parts. Equipment from reputable suppliers ensures quick access to parts and technical support, sustaining continuous operation.

Operational Considerations for Optimal Performance

Load Capacity and Force Output

A reciprocator must handle loads typical to its application without overload or loss of precision. Selecting a model with adequate force output capability ensures reliable operation under full production conditions.

Energy Efficiency

Reducing power consumption is increasingly important in large-scale operations. Efficient motor and actuator designs reduce operating costs and contribute to environmental sustainability.

Noise and Vibration Management

High-volume workplaces require equipment that operates quietly and with minimal vibration to improve worker comfort and protect sensitive adjacent devices or products.

Case Study: Reciprocators in Packaging Industry

In packaging lines, reciprocators are commonly used in cutting and sealing operations, which occur at very high speeds. Machines that perform these actions need to handle continuous cycles with tight dimensional tolerances.

Challenges Addressed

- High-speed strokes without wear-induced accuracy losses

- Integration with automated feeders and conveyors

- Minimizing downtime through easy maintenance

Solutions Implemented

- Use of lightweight, durable materials in moving parts

- Incorporation of electronic stroke length adjustment

- Condition monitoring sensors for real-time diagnostics

This integration has led to greater throughput, reduced waste, and improved product consistency.

How to Select the Right Reciprocator for Your High-Volume Production

Analyze Production Requirements

Assess the production speed, load types, stroke length, and accuracy needed.

Evaluate Machine Specifications

Check the reciprocator's cycle rate, durability ratings, materials used, and control features.

Consider Vendor Support

Choose suppliers who provide comprehensive after-sales support, spare parts availability, and maintenance training.

Test Before Commitment

If possible, trial the reciprocator in a controlled environment to identify any unforeseen issues or adjustments required.

Frequently Asked Questions (FAQ)

1. What types of materials are best for reciprocators used in high-volume production?

High-strength alloys, hardened steels, and composite materials with low friction and high wear resistance are preferred for durability and performance in demanding environments.

2. How important is stroke length adjustability in a reciprocator?

Very important. Adjustable stroke lengths allow customization for different tasks and products, enhancing machine flexibility and reducing the need for multiple devices.

3. Can reciprocators be integrated into fully automated production lines?

Yes, modern reciprocators often come with programmable controls and standard interfaces, facilitating integration with PLCs, conveyors, and robotic systems.

4. What maintenance practices extend the life of a reciprocator?

Regular lubrication, scheduled inspections, prompt replacement of worn parts, and use of predictive maintenance tools all contribute to longer reciprocator lifespan and reliable operation.

5. How does noise and vibration control impact reciprocator performance in high-volume settings?

Reducing noise and vibration enhances operator comfort, reduces equipment fatigue, and helps maintain precision, all vital for sustained high-volume productivity.

Conclusion

Selecting a reciprocator suitable for high-volume production requires careful consideration of speed, durability, precision, integration capability, and maintenance features. By prioritizing advanced materials, robust designs, and smart control systems, manufacturers can achieve efficient, reliable, and cost-effective operations. Understanding these factors empowers businesses to optimize their production lines, improve quality, and remain competitive in fast-paced industrial markets.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.