Content Menu

● Introduction

● Ramseier Koatings Technologies Holdings Ltd.

>> Overview

>> Key Offerings

● Other Notable Manufacturers and Suppliers

>> 1. OOO INTER COOL AGRO

>> 2. LLC PROMKIPAVTOMATIKA ENGINEERING

>> 3. CLEVERTECH

>> 4. Nova Solutions

>> 5. DAAC System Uzbekistan

● The Importance of Smart Control Systems

● Future Trends in Smart Control Systems

>> 1. Integration of AI and Machine Learning

>> 2. Increased Connectivity

>> 3. Focus on Sustainability

>> 4. Enhanced User Interfaces

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What are smart control systems?

>> 2. How do smart control systems benefit businesses?

>> 3. What industries use smart control systems?

>> 4. What is the future of smart control systems?

>> 5. How can I choose the right smart control system for my business?

Introduction

In the rapidly evolving landscape of technology, smart control systems have become essential for enhancing efficiency and automation across various industries. Uzbekistan, with its growing industrial base, is home to several manufacturers and suppliers specializing in smart control systems. This article highlights the top manufacturers and suppliers in Uzbekistan, focusing on their contributions to the smart control system market. Among these, Ramseier Koatings Technologies Holdings Ltd. stands out as a leader in innovation and quality.

Ramseier Koatings Technologies Holdings Ltd.

Overview

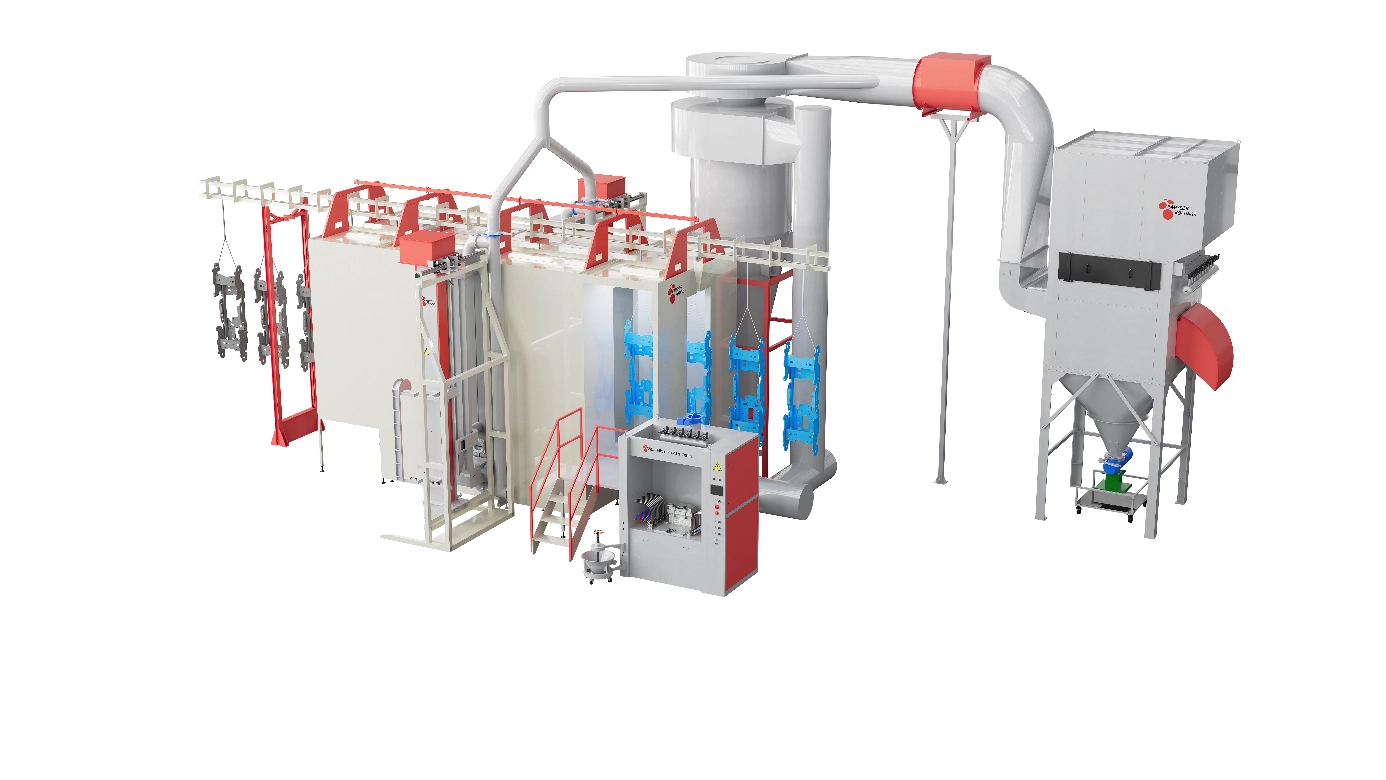

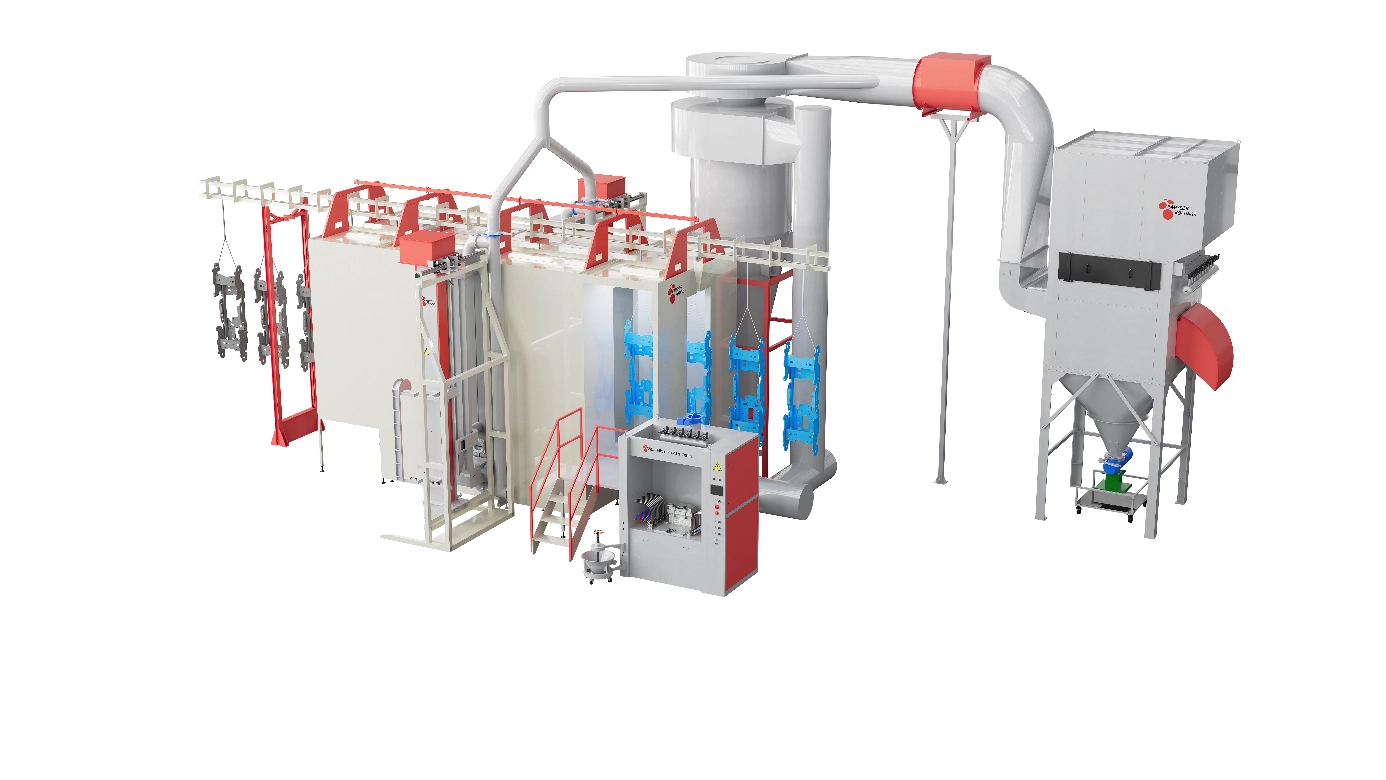

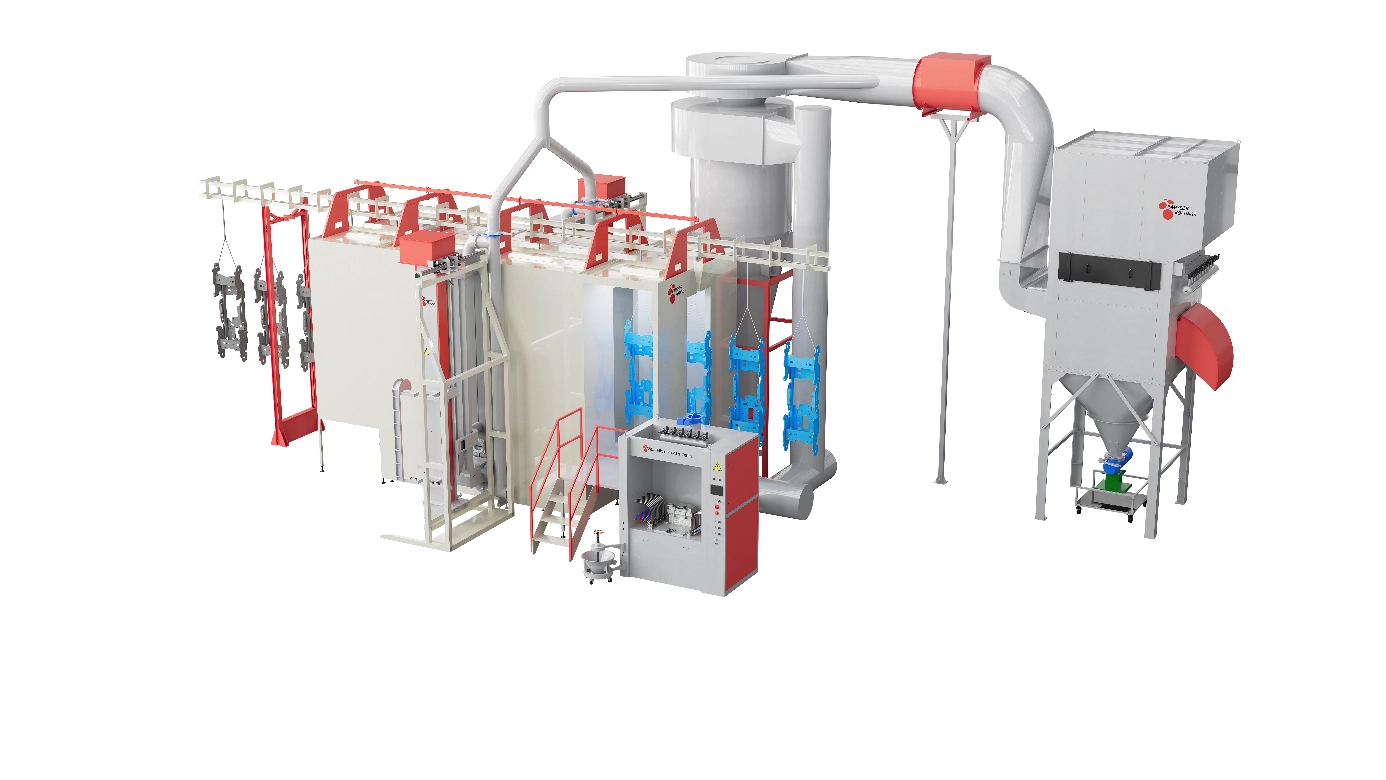

Ramseier Koatings Technologies Holdings Ltd. is a prominent player in the smart control system sector, known for its cutting-edge technology and commitment to quality. The company specializes in developing advanced control systems that cater to various industries, including manufacturing, agriculture, and energy. Their products are designed to optimize processes, reduce energy consumption, and enhance overall operational efficiency.

Key Offerings

- Smart Control Solutions: Ramseier offers a range of smart control solutions that integrate seamlessly with existing systems, providing real-time monitoring and control capabilities.

- Customizable Systems: Understanding that each industry has unique needs, Ramseier provides customizable solutions tailored to specific operational requirements.

- Sustainability Focus: The company emphasizes sustainable practices, ensuring that their smart control systems contribute to energy efficiency and reduced environmental impact.

Other Notable Manufacturers and Suppliers

1. OOO INTER COOL AGRO

Located in Tashkent, OOO INTER COOL AGRO specializes in agricultural smart control systems. Their innovative solutions help farmers monitor and manage their operations more effectively, leading to increased productivity and sustainability.

2. LLC PROMKIPAVTOMATIKA ENGINEERING

This company focuses on automation and control systems for various industrial applications. Their expertise in smart control technologies makes them a reliable partner for businesses looking to enhance their operational efficiency.

3. CLEVERTECH

CLEVERTECH is known for its smart home automation solutions. They provide integrated systems that allow users to control lighting, heating, and security from a single interface, making homes more efficient and secure.

4. Nova Solutions

Nova Solutions offers a comprehensive range of automation control solutions, including programmable logic controllers (PLCs) and software for various industries. Their commitment to innovation positions them as a key player in the smart control system market.

5. DAAC System Uzbekistan

DAAC System provides customized IT solutions and technical support for businesses. Their focus on smart control systems helps clients streamline operations and improve productivity.

The Importance of Smart Control Systems

Smart control systems are integral to modern industrial operations. They provide numerous benefits, including:

- Increased Efficiency: By automating processes, businesses can reduce manual intervention, leading to faster and more accurate operations.

- Cost Savings: Smart control systems help in monitoring energy usage and optimizing resource allocation, resulting in significant cost savings.

- Enhanced Data Analytics: These systems collect and analyze data in real-time, providing valuable insights that can drive strategic decision-making.

- Improved Safety: Automation reduces the risk of human error, enhancing workplace safety and compliance with regulations.

Future Trends in Smart Control Systems

As technology continues to advance, several trends are shaping the future of smart control systems:

1. Integration of AI and Machine Learning

The incorporation of artificial intelligence (AI) and machine learning into smart control systems is expected to enhance their capabilities. These technologies will enable systems to learn from data patterns, improving decision-making processes and predictive maintenance.

2. Increased Connectivity

With the rise of the Internet of Things (IoT), smart control systems will become more interconnected. This connectivity will allow for better data sharing and collaboration between different systems, leading to more cohesive operations.

3. Focus on Sustainability

As businesses increasingly prioritize sustainability, smart control systems will play a crucial role in reducing energy consumption and minimizing environmental impact. Manufacturers will need to develop solutions that align with these goals.

4. Enhanced User Interfaces

User experience will be a key focus, with manufacturers striving to create more intuitive and user-friendly interfaces. This will make it easier for operators to interact with smart control systems and leverage their full potential.

Conclusion

The smart control system market in Uzbekistan is thriving, with several manufacturers and suppliers leading the way in innovation and quality. Ramseier Koatings Technologies Holdings Ltd. is at the forefront, offering advanced solutions that cater to various industries. As technology continues to evolve, the importance of smart control systems will only grow, driving efficiency and sustainability across sectors.

Frequently Asked Questions (FAQs)

1. What are smart control systems?

Smart control systems are automated systems that manage and optimize processes in various industries, enhancing efficiency and reducing human intervention.

2. How do smart control systems benefit businesses?

They provide increased efficiency, cost savings, enhanced data analytics, and improved safety by automating processes and reducing manual errors.

3. What industries use smart control systems?

Smart control systems are used in various industries, including manufacturing, agriculture, energy, and smart home automation.

4. What is the future of smart control systems?

The future includes the integration of AI, increased connectivity through IoT, a focus on sustainability, and enhanced user interfaces.

5. How can I choose the right smart control system for my business?

Consider your specific operational needs, the scalability of the system, the level of customization available, and the support offered by the manufacturer.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.