Content Menu

● Understanding Smart Control Systems

>> What is a Smart Control System?

>> Benefits of Smart Control Systems

● Key Features to Look for in a Smart Control System

>> 1. User-Friendly Interface

>> 2. Real-Time Monitoring

>> 3. Integration with Existing Systems

>> 4. Advanced Analytics

>> 5. Scalability

● Factors to Consider When Choosing a Smart Control System

>> 1. Budget

>> 2. Vendor Reputation

>> 3. Support and Training

>> 4. Compliance with Regulations

>> 5. Customization Options

● Implementing a Smart Control System in Your Spray Booth

>> 1. Assess Your Current Setup

>> 2. Define Your Goals

>> 3. Involve Your Team

>> 4. Plan for Integration

>> 5. Monitor and Adjust

● Common Challenges and Solutions

>> 1. Resistance to Change

>> 2. Technical Issues

>> 3. Data Overload

>> 4. Integration Difficulties

>> 5. Cost Concerns

● Future Trends in Smart Control Systems

>> 1. Increased Automation

>> 2. Enhanced Connectivity

>> 3. Artificial Intelligence Integration

>> 4. Sustainability Focus

>> 5. Customization and Flexibility

● Conclusion

>> Frequently Asked Questions

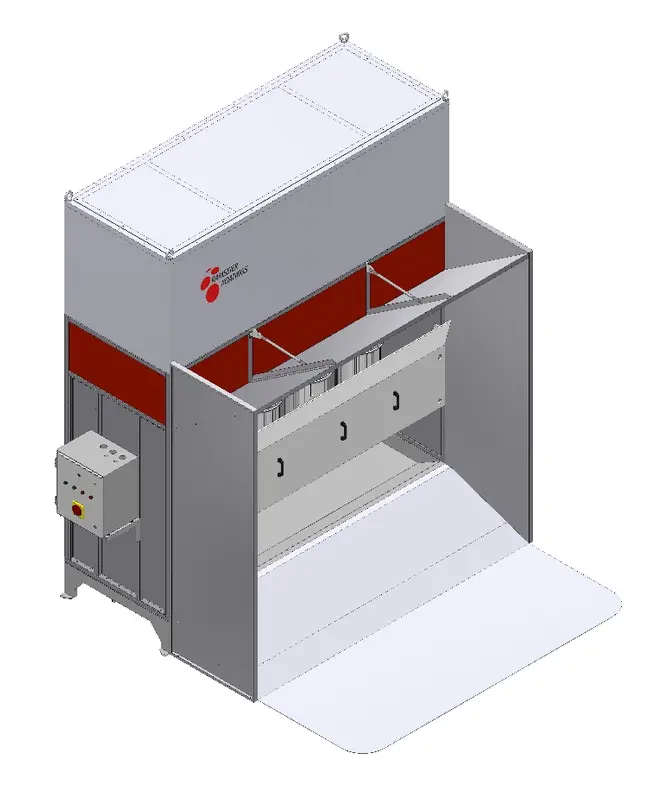

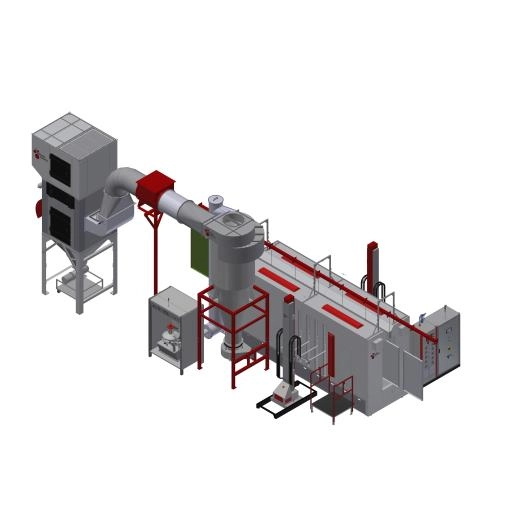

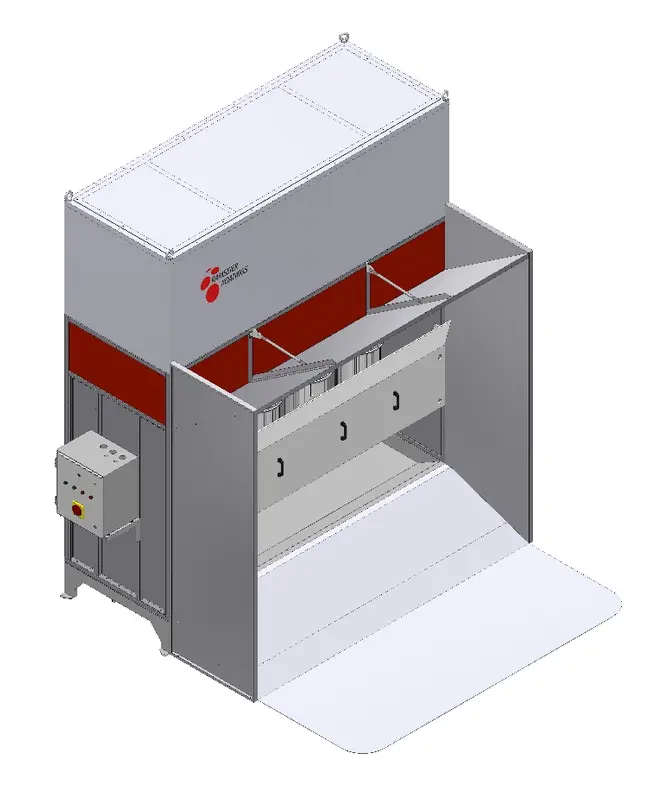

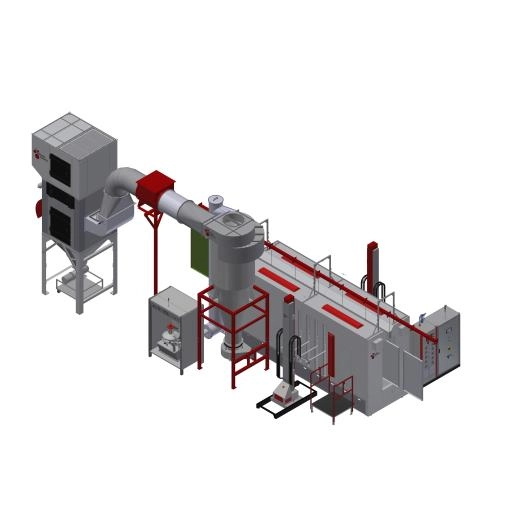

In the world of industrial painting and finishing, the efficiency and quality of the spray booth operation can significantly impact the final product. A smart control system is essential for optimizing these processes, ensuring safety, and maintaining high standards of quality. This guide will explore the key considerations when selecting a smart control system for your spray booth, including features, benefits, and best practices.

Understanding Smart Control Systems

What is a Smart Control System?

A smart control system is an advanced technology that automates and optimizes the operation of equipment, such as spray booths. These systems utilize sensors, software, and connectivity to monitor and control various parameters, including temperature, humidity, airflow, and spray patterns. By integrating these elements, smart control systems enhance the efficiency and effectiveness of spray booth operations.

Benefits of Smart Control Systems

1. Increased Efficiency: Smart control systems can optimize the use of resources, reducing waste and improving productivity. By automating processes, they minimize the need for manual intervention, allowing operators to focus on more critical tasks.

2. Enhanced Quality Control: With real-time monitoring and data analysis, smart control systems help maintain consistent quality in the finishing process. They can detect anomalies and adjust parameters automatically to ensure that the final product meets the required specifications.

3. Improved Safety: These systems can monitor environmental conditions and alert operators to potential hazards, such as excessive fumes or temperature fluctuations. This proactive approach to safety helps protect workers and equipment.

4. Data Collection and Analysis: Smart control systems gather valuable data that can be analyzed to identify trends, optimize processes, and make informed decisions. This data-driven approach can lead to continuous improvement in operations.

5. Remote Monitoring and Control: Many smart control systems offer remote access capabilities, allowing operators to monitor and control the spray booth from anywhere. This feature is particularly useful for multi-site operations or for managers who need to oversee multiple processes simultaneously.

Key Features to Look for in a Smart Control System

When selecting a smart control system for your spray booth, consider the following features:

1. User-Friendly Interface

A user-friendly interface is crucial for ensuring that operators can easily navigate the system. Look for systems with intuitive dashboards, clear visualizations, and customizable settings that allow users to tailor the interface to their specific needs.

2. Real-Time Monitoring

Real-time monitoring capabilities enable operators to track critical parameters continuously. This feature is essential for maintaining optimal conditions within the spray booth and ensuring that any deviations are addressed promptly.

3. Integration with Existing Systems

Choose a smart control system that can seamlessly integrate with your existing equipment and software. This compatibility will facilitate a smoother transition and allow for better data sharing across different systems.

4. Advanced Analytics

Advanced analytics capabilities can provide insights into operational performance, helping to identify areas for improvement. Look for systems that offer predictive analytics, which can forecast potential issues before they arise.

5. Scalability

As your business grows, your smart control system should be able to scale accordingly. Choose a system that can accommodate additional features, sensors, or integrations as needed.

Factors to Consider When Choosing a Smart Control System

1. Budget

Your budget will play a significant role in determining which smart control system is right for you. While it may be tempting to opt for the cheapest option, consider the long-term benefits of investing in a high-quality system that offers advanced features and reliability.

2. Vendor Reputation

Research potential vendors to ensure they have a solid reputation in the industry. Look for customer reviews, case studies, and testimonials to gauge the reliability and performance of their systems.

3. Support and Training

Consider the level of support and training offered by the vendor. A good vendor will provide comprehensive training for your staff and ongoing support to address any issues that may arise.

4. Compliance with Regulations

Ensure that the smart control system complies with industry regulations and standards. This compliance is crucial for maintaining safety and quality in your operations.

5. Customization Options

Every spray booth operation is unique, so look for a smart control system that offers customization options. This flexibility will allow you to tailor the system to your specific processes and requirements.

Implementing a Smart Control System in Your Spray Booth

1. Assess Your Current Setup

Before implementing a smart control system, assess your current spray booth setup. Identify any pain points or inefficiencies that the new system should address. This assessment will help you choose the right features and capabilities.

2. Define Your Goals

Clearly define your goals for implementing a smart control system. Whether you aim to improve efficiency, enhance quality, or ensure safety, having specific objectives will guide your decision-making process.

3. Involve Your Team

Involve your team in the selection and implementation process. Their insights and experiences can provide valuable input and help ensure that the chosen system meets the needs of all users.

4. Plan for Integration

Develop a plan for integrating the smart control system with your existing equipment and processes. This plan should include timelines, responsibilities, and any necessary training for staff.

5. Monitor and Adjust

After implementing the smart control system, continuously monitor its performance and make adjustments as needed. Regularly review data and feedback from operators to identify areas for improvement.

Common Challenges and Solutions

1. Resistance to Change

One of the most common challenges when implementing a new system is resistance from staff. To overcome this, provide thorough training and emphasize the benefits of the new system. Involve employees in the decision-making process to foster a sense of ownership.

2. Technical Issues

Technical issues can arise during the implementation of a smart control system. Work closely with the vendor to address any problems promptly. Ensure that your team is trained to troubleshoot common issues.

3. Data Overload

With advanced analytics capabilities, smart control systems can generate a significant amount of data. To avoid data overload, focus on key performance indicators (KPIs) that align with your goals. Use dashboards to visualize important metrics and facilitate decision-making.

4. Integration Difficulties

Integrating a new system with existing equipment can be challenging. Choose a vendor that offers strong support for integration and has experience working with your specific equipment.

5. Cost Concerns

While the initial investment in a smart control system may be significant, consider the long-term savings and benefits. A well-implemented system can lead to reduced waste, improved efficiency, and higher quality products, ultimately offsetting the initial costs.

Future Trends in Smart Control Systems

1. Increased Automation

The trend towards increased automation in manufacturing is expected to continue. Smart control systems will play a crucial role in this shift, enabling more efficient and precise operations.

2. Enhanced Connectivity

As the Internet of Things (IoT) continues to evolve, smart control systems will become even more interconnected. This connectivity will allow for better data sharing and collaboration across different systems and processes.

3. Artificial Intelligence Integration

The integration of artificial intelligence (AI) into smart control systems will enhance their capabilities. AI can analyze data more effectively, predict potential issues, and optimize processes in real-time.

4. Sustainability Focus

With growing concerns about environmental impact, smart control systems will increasingly focus on sustainability. This focus will include optimizing energy use, reducing waste, and ensuring compliance with environmental regulations.

5. Customization and Flexibility

Future smart control systems will offer even greater customization and flexibility, allowing businesses to tailor solutions to their specific needs. This adaptability will be essential in a rapidly changing industrial landscape.

Conclusion

Choosing the right smart control system for your spray booth is a critical decision that can significantly impact your operations. By understanding the benefits, features, and implementation strategies, you can make an informed choice that enhances efficiency, quality, and safety. As technology continues to evolve, staying informed about trends and advancements will ensure that your spray booth remains competitive in the industry.

Frequently Asked Questions

1. What is the primary benefit of a smart control system in a spray booth?

- The primary benefit is increased efficiency, as these systems automate processes and optimize resource use.

2. How do I choose the right smart control system for my needs?

- Consider factors such as budget, vendor reputation, features, and integration capabilities.

3. What challenges might I face when implementing a smart control system?

- Common challenges include resistance to change, technical issues, and integration difficulties.

4. Can a smart control system help improve safety in my spray booth?

- Yes, these systems monitor environmental conditions and alert operators to potential hazards.

5. What future trends should I be aware of regarding smart control systems?

- Key trends include increased automation, enhanced connectivity, AI integration, sustainability focus, and greater customization options.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.