Content Menu

● Understanding Powder Coating

>> What is Powder Coating?

>> Advantages of Powder Coating

● Understanding Wet Painting

>> What is Wet Painting?

>> Advantages of Wet Painting

● Cost Comparison

>> Initial Setup Costs

>> Material Costs

>> Labor Costs

>> Long-Term Cost Effectiveness

● Environmental Considerations

>> Powder Coating and the Environment

>> Wet Painting and Environmental Impact

● Conclusion

● Frequently Asked Questions

>> 1. What is the main difference between powder coating and wet painting?

>> 2. Which method is more environmentally friendly?

>> 3. Is powder coating more expensive than wet painting?

>> 4. Can I use powder coating on all materials?

>> 5. How long does each process take?

When it comes to finishing metal surfaces, two popular methods stand out: powder coating and wet painting. Each technique has its own set of advantages and disadvantages, particularly in terms of cost-effectiveness. This article will explore the differences between these two methods, helping you make an informed decision for your next project.

Understanding Powder Coating

What is Powder Coating?

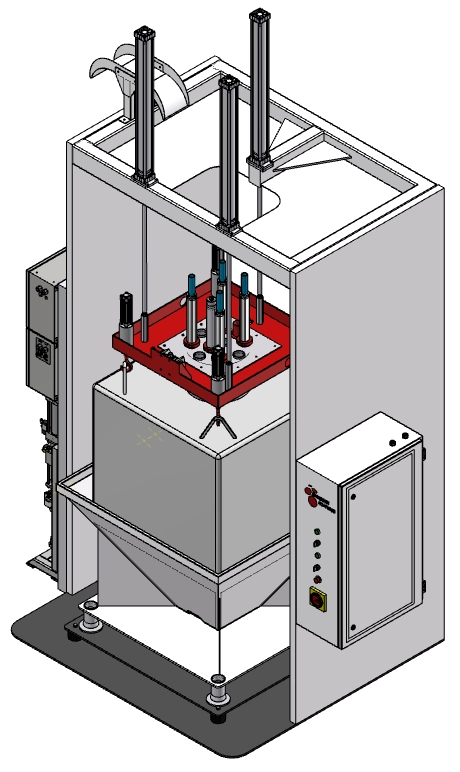

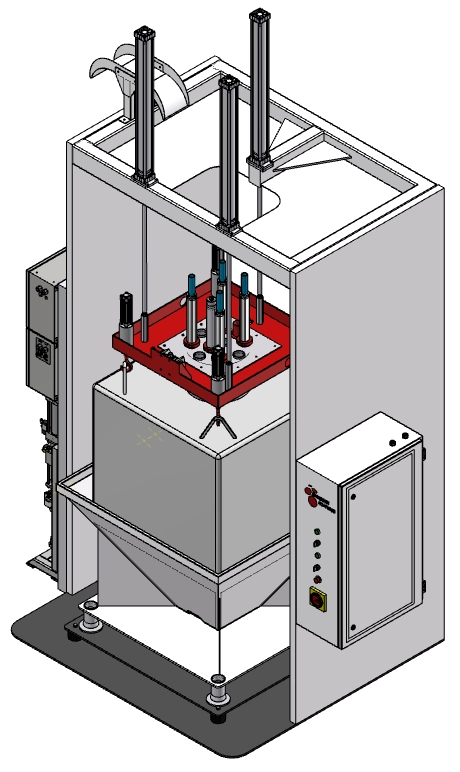

Powder coating is a dry finishing process that uses finely ground particles of pigment and resin, which are electrostatically charged and sprayed onto a surface. The coated item is then heated in an oven, where the powder melts and forms a durable, protective layer.

Advantages of Powder Coating

1. Durability: Powder coating creates a thicker, more durable finish compared to wet paint. It is resistant to chipping, scratching, and fading, making it ideal for outdoor applications.

2. Environmental Impact: Powder coating is more environmentally friendly as it emits fewer volatile organic compounds (VOCs) than traditional paints. This makes it a safer option for both workers and the environment.

3. Efficiency: The powder coating process is generally faster than wet painting. Once the item is coated, it can be cured quickly in an oven, reducing overall production time.

4. Cost-Effectiveness: Although the initial setup costs for powder coating equipment can be higher, the long-term savings from reduced waste and lower maintenance costs can make it more economical over time.

Understanding Wet Painting

What is Wet Painting?

Wet painting involves applying liquid paint to a surface using a spray gun or brush. The paint consists of pigments suspended in a solvent, which evaporates as the paint dries, leaving a colored film on the surface.

Advantages of Wet Painting

1. Lower Initial Costs: The equipment needed for wet painting is generally less expensive than that for powder coating. This makes it a more accessible option for small businesses or projects with limited budgets.

2. Versatility: Wet paint can be applied to a wider variety of materials, including those that may be sensitive to heat, which is a requirement for powder coating.

3. Color Variety: Wet painting offers a broader range of colors and finishes, allowing for more customization options.

4. Ease of Application: Wet paint can be easier to apply in certain situations, especially for small or intricate parts where powder coating might be challenging.

Cost Comparison

Initial Setup Costs

The initial investment for powder coating equipment, including spray guns and curing ovens, can be significant. In contrast, wet painting requires less specialized equipment, making it a more affordable option for startups or small-scale operations.

Material Costs

While the cost of powder itself can be higher than that of liquid paint, powder coating is more efficient. Excess powder can be collected and reused, reducing material waste. Wet paint, on the other hand, often results in more overspray and waste, which can increase costs over time.

Labor Costs

Powder coating typically requires less labor than wet painting. The curing process is faster, and the need for multiple coats (primer and paint) in wet painting can increase labor costs. Additionally, the durability of powder-coated finishes means less frequent reapplication, further reducing labor expenses.

Long-Term Cost Effectiveness

In the long run, powder coating often proves to be more cost-effective due to its durability and lower maintenance requirements. While wet paint may be cheaper initially, the need for frequent touch-ups and reapplications can add up, making powder coating a more economical choice for high-use items.

Environmental Considerations

Powder Coating and the Environment

Powder coating is considered more environmentally friendly due to its low VOC emissions and the ability to recycle excess powder. This not only reduces waste but also minimizes the environmental impact of the coating process.

Wet Painting and Environmental Impact

Wet painting, while versatile, often involves solvents that can release harmful VOCs into the atmosphere. This can contribute to air pollution and pose health risks to workers. Additionally, the disposal of leftover paint and solvents can be more complicated and costly.

Conclusion

When deciding between powder coating and wet painting, it is essential to consider the specific needs of your project. If durability, environmental impact, and long-term cost-effectiveness are your primary concerns, powder coating is likely the better choice. However, if you require a wider range of colors, lower initial costs, or are working with heat-sensitive materials, wet painting may be more suitable.

Ultimately, both methods have their place in the finishing industry, and the best choice will depend on your unique requirements and budget.

Frequently Asked Questions

1. What is the main difference between powder coating and wet painting?

Powder coating uses dry powder that is cured with heat, resulting in a thicker, more durable finish, while wet painting involves liquid paint that dries as the solvent evaporates.

2. Which method is more environmentally friendly?

Powder coating is generally more environmentally friendly due to lower VOC emissions and the ability to recycle excess powder.

3. Is powder coating more expensive than wet painting?

While the initial setup costs for powder coating can be higher, it is often more cost-effective in the long run due to its durability and lower maintenance needs.

4. Can I use powder coating on all materials?

Powder coating is not suitable for all materials, particularly those that are heat-sensitive. Wet painting can be applied to a wider variety of surfaces.

5. How long does each process take?

Powder coating is typically faster due to its quick curing time, while wet painting can take longer due to the need for multiple coats and drying time.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.