Content Menu

● Introduction

● Understanding Powder Coating

>> What is Powder Coating?

>> Benefits of Powder Coating

● The Role of Smart Automation in Powder Coating

>> What is Smart Automation?

>> Key Technologies Driving Smart Automation

>>> Robotics and Automated Systems

>>> IoT and Real-Time Monitoring

>>> Machine Learning and AI

● Advantages of Smart Automation in Powder Coating

>> Increased Efficiency

>> Enhanced Quality Control

>> Cost Savings

>> Flexibility and Customization

● Challenges in Implementing Smart Automation

>> High Initial Investment

>> Integration with Existing Systems

>> Cybersecurity Risks

● Future Trends in Smart Powder Coating Automation

>> Sustainable Practices

>> Customization and Personalization

>> Advanced Data Analytics

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of using smart automation in powder coating?

>> 2. How does IoT technology enhance powder coating processes?

>> 3. What are the challenges of implementing smart automation in powder coating?

>> 4. Can smart automation improve the customization of powder coating applications?

>> 5. What future trends should we expect in smart powder coating automation?

Introduction

In the modern manufacturing landscape, the demand for efficiency, precision, and customization has never been higher. One area that has seen significant advancements is powder coating, a process that provides a durable finish to a variety of materials. Smart automation technologies are revolutionizing custom powder coating applications, enabling manufacturers to enhance productivity, reduce waste, and improve product quality. This article explores the various aspects of smart automation in powder coating, including its benefits, technologies involved, and future trends.

Understanding Powder Coating

What is Powder Coating?

Powder coating is a finishing process that involves applying a dry powder to a surface, which is then cured under heat to form a hard, protective layer. Unlike traditional liquid paints, powder coatings do not require solvents, making them more environmentally friendly. The process is widely used in industries such as automotive, furniture, and appliances due to its durability and aesthetic appeal.

Benefits of Powder Coating

1. Durability: Powder coatings are resistant to chipping, scratching, fading, and wearing, making them ideal for high-use items.

2. Environmental Impact: With no volatile organic compounds (VOCs), powder coating is a more sustainable option compared to traditional paints.

3. Cost-Effectiveness: The efficiency of the powder coating process can lead to lower production costs over time.

The Role of Smart Automation in Powder Coating

What is Smart Automation?

Smart automation refers to the integration of advanced technologies such as robotics, artificial intelligence (AI), and the Internet of Things (IoT) into manufacturing processes. In powder coating, these technologies enable real-time monitoring, adaptive processing, and enhanced control over the coating application.

Key Technologies Driving Smart Automation

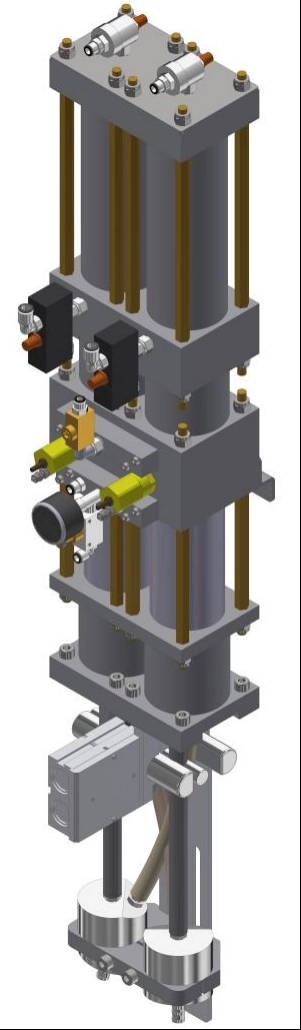

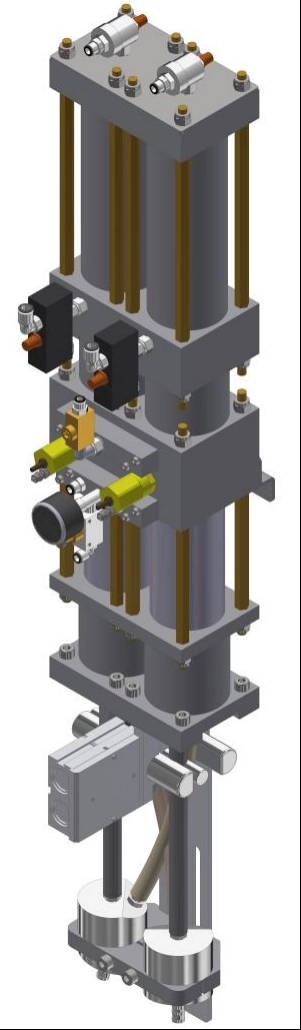

Robotics and Automated Systems

Robotic arms equipped with advanced spray nozzles are at the forefront of smart automation in powder coating. These systems can be programmed to apply coatings with high precision, ensuring uniform coverage and reducing human error. The use of robotics also allows for faster production rates, which is crucial in high-demand environments.

IoT and Real-Time Monitoring

IoT technology enables the connection of various components within the powder coating system, allowing for real-time data collection and analysis. Sensors can monitor parameters such as temperature, humidity, and powder flow, automatically adjusting settings to maintain optimal conditions. This level of automation not only enhances quality but also minimizes material waste.

Machine Learning and AI

Machine learning algorithms can analyze data from the coating process to identify patterns and optimize operations. For instance, AI can predict when maintenance is needed, reducing downtime and improving overall efficiency. By learning from past applications, these systems can continuously improve their performance.

Advantages of Smart Automation in Powder Coating

Increased Efficiency

Smart automation significantly increases the efficiency of powder coating processes. Automated systems can operate continuously, reducing the time required for manual interventions. This leads to faster turnaround times and the ability to handle larger volumes of work.

Enhanced Quality Control

With automated systems, manufacturers can achieve a higher level of consistency in their coatings. Real-time monitoring ensures that any deviations from the desired parameters are immediately corrected, resulting in a superior finish. This is particularly important in custom applications where quality is paramount.

Cost Savings

While the initial investment in smart automation technology can be substantial, the long-term savings are significant. Reduced labor costs, lower material waste, and increased production rates contribute to a more profitable operation. Additionally, the durability of powder coatings means fewer reworks and repairs.

Flexibility and Customization

Smart automation allows for greater flexibility in production. Manufacturers can easily switch between different powder types and colors, accommodating custom orders without significant downtime. This adaptability is essential in today's market, where customer preferences are constantly evolving.

Challenges in Implementing Smart Automation

High Initial Investment

One of the primary barriers to adopting smart automation in powder coating is the high initial cost. Robotic systems and advanced sensors require significant capital investment, which can be a challenge for small to medium-sized enterprises.

Integration with Existing Systems

Integrating smart automation technologies into existing powder coating lines can be complex. Manufacturers must assess compatibility and may need to retrofit older equipment, which can involve additional costs and technical expertise.

Cybersecurity Risks

As manufacturing processes become more connected, the risk of cyber threats increases. Ensuring the security of automated systems is crucial to protect sensitive data and maintain operational integrity.

Future Trends in Smart Powder Coating Automation

Sustainable Practices

The push for sustainability is influencing the development of new powder coating technologies. Manufacturers are increasingly adopting low-VOC powders and energy-efficient curing processes to reduce their environmental impact. Smart automation plays a key role in optimizing these processes for sustainability.

Customization and Personalization

As consumer demand for personalized products grows, the ability to quickly adapt powder coating processes becomes essential. Smart automation systems can facilitate rapid changes in production, allowing manufacturers to meet specific customer requirements efficiently.

Advanced Data Analytics

The future of smart automation in powder coating will likely see an increased focus on data analytics. By leveraging big data, manufacturers can gain insights into their operations, leading to further optimizations and innovations in the coating process.

Conclusion

Smart automation is transforming the landscape of custom powder coating applications, offering numerous benefits such as increased efficiency, enhanced quality control, and cost savings. As technology continues to evolve, manufacturers who embrace these advancements will be better positioned to meet the demands of a competitive market. The integration of robotics, IoT, and AI into powder coating processes not only improves operational performance but also paves the way for a more sustainable and customizable future.

Frequently Asked Questions

1. What is the main advantage of using smart automation in powder coating?

The main advantage is increased efficiency, which leads to faster production rates and reduced labor costs while maintaining high-quality standards.

2. How does IoT technology enhance powder coating processes?

IoT technology allows for real-time monitoring and adjustments of the coating parameters, ensuring optimal conditions and minimizing material waste.

3. What are the challenges of implementing smart automation in powder coating?

Challenges include high initial investment costs, integration with existing systems, and cybersecurity risks associated with connected technologies.

4. Can smart automation improve the customization of powder coating applications?

Yes, smart automation allows for quick changes in production processes, enabling manufacturers to accommodate custom orders efficiently.

5. What future trends should we expect in smart powder coating automation?

Future trends include a focus on sustainability, advanced data analytics for operational insights, and increased customization capabilities.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.