Content Menu

● Introduction

● What are Powder Sieve Systems?

>> Types of Powder Sieve Systems

● Why Choose Professional Powder Sieve System Manufacturers?

>> Expertise and Innovation

>> Customization and OEM Services

>> Quality and Compliance

● Applications of Powder Sieve Systems

>> Chemical and Metallurgical Industries

>> Pharmaceutical and Food Industries

>> Battery and Additive Manufacturing

● Key Features of Modern Powder Sieve Systems

>> High Precision and Efficiency

>> Ease of Maintenance and Operation

>> Versatility and Flexibility

● How to Select the Right Powder Sieve System Manufacturer

>> Assess Industry Experience

>> Evaluate Technological Capabilities

>> Consider Customization and Support

● Conclusion

● Frequently Asked Questions (FAQs)

Introduction

As a leading Chinese powder sieve system manufacturer, we specialize in providing OEM services to international powder sieve system brands, wholesalers, and producers. In this comprehensive article, we will explore the critical role of powder sieve systems in various industries, highlight the latest technologies, and explain why partnering with experienced powder sieve system manufacturers can elevate your production efficiency and product quality.

What are Powder Sieve Systems?

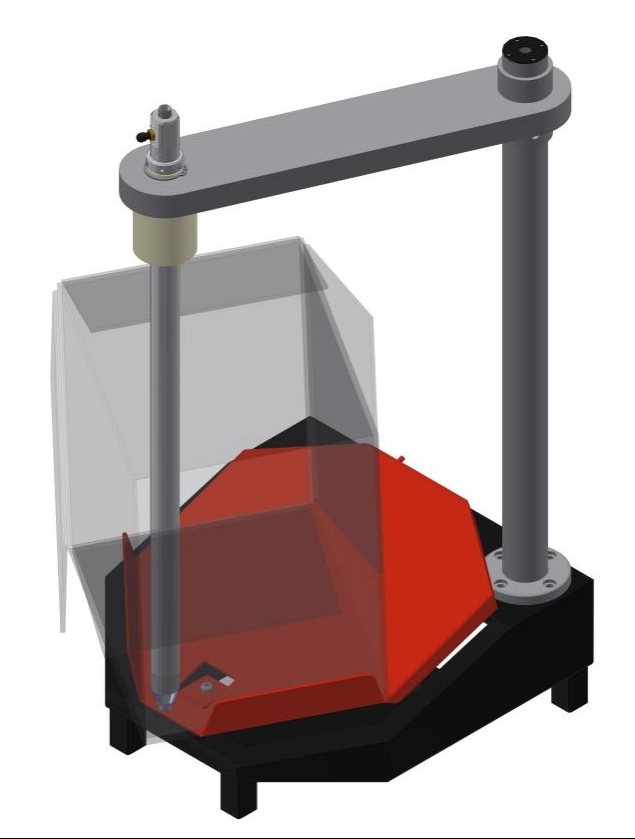

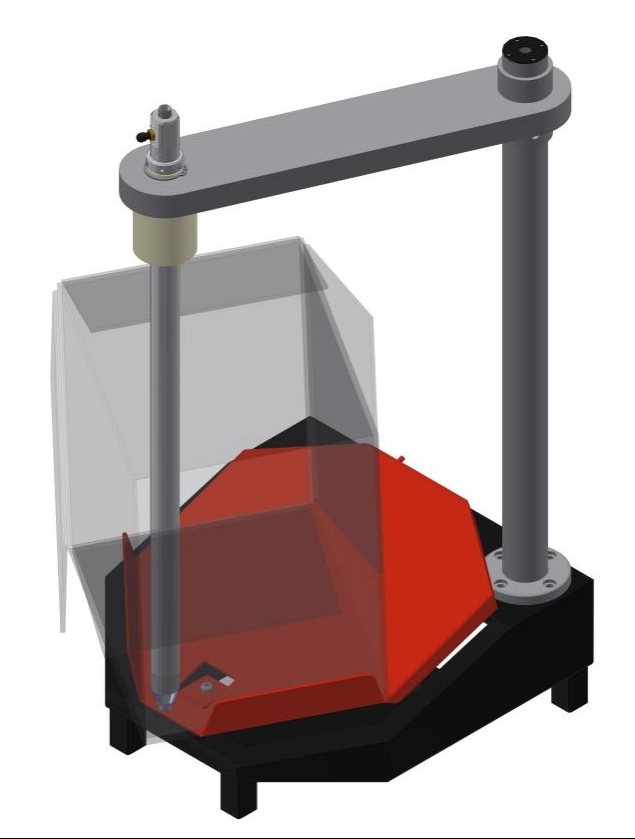

Powder sieve systems are industrial machines designed to separate powders into different particle sizes, remove contaminants, and ensure consistent product quality. These systems are widely used in industries such as chemicals, pharmaceuticals, metallurgy, food processing, and battery materials manufacturing. The demand for precise particle size distribution and high throughput has driven innovation in powder sieve system manufacturing[1][2][4].

Types of Powder Sieve Systems

- Vibratory Sieves: Use vibration to separate particles based on size.

- Tumbler Screening Machines: Employ a 3D motion to achieve efficient particle separation.

- Ultrasonic Sieves: Use ultrasonic waves to prevent screen blinding and improve sieving efficiency.

- Air Classifiers: Utilize airflow to classify powders without moving parts, ideal for fine and abrasive powders[1][2][3].

Why Choose Professional Powder Sieve System Manufacturers?

Expertise and Innovation

Experienced powder sieve system manufacturers invest heavily in research and development to innovate and improve screening technologies. For example, some manufacturers have developed advanced multi-frequency sieving technology and ultrasonic deblinding systems to handle ultra-fine powders and difficult-to-screen materials[1][3].

Customization and OEM Services

OEM powder sieve system manufacturers provide tailored solutions to meet the specific needs of brands, wholesalers, and producers worldwide. They offer customization in machine design, screen mesh size, and material handling to optimize production lines and reduce operational costs[3][6].

Quality and Compliance

Top manufacturers ensure their powder sieve systems comply with international standards, especially for sensitive industries like pharmaceuticals and food processing. Hygienic designs, easy cleaning features, and durable components are standard to maintain product integrity and safety[4][9].

Applications of Powder Sieve Systems

Chemical and Metallurgical Industries

Powder sieve systems are essential for separating metal powders, chemical additives, and minerals. Accurate particle size distribution improves product performance and reduces waste. For example, specialized lines for metal silicon powder processing have been developed to address challenges in particle control and cost efficiency[3][6].

Pharmaceutical and Food Industries

In these sectors, powder sieve systems ensure the removal of lumps and contaminants, maintaining product purity and meeting strict hygiene standards. Vibratory and ultrasonic sieves are commonly used to achieve high yields and consistent quality[2][4][9].

Battery and Additive Manufacturing

The production of battery materials and 3D printing powders requires precise sieving to ensure uniform particle size, which directly impacts the performance of the final product. Advanced air classifiers and ultrasonic sieves are increasingly adopted in these fields[2][7].

Key Features of Modern Powder Sieve Systems

High Precision and Efficiency

Modern powder sieve systems achieve particle separation down to as fine as 10 microns with yields exceeding 95%. Technologies like ultrasonic deblinding and multi-frequency vibration enhance screening accuracy and throughput[1][2][3].

Ease of Maintenance and Operation

Designs often include tool-free screen replacement, quick disassembly for cleaning, and low-energy consumption motors. These features reduce downtime and operational costs, making powder sieve systems highly efficient for continuous production[9].

Versatility and Flexibility

Manufacturers offer various sieve types (circular, rectangular, vibrating, tumbler) and configurations (open, closed, inline with pneumatic conveyors) to suit diverse powder types and production requirements[1][9].

How to Select the Right Powder Sieve System Manufacturer

Assess Industry Experience

Choose manufacturers with proven expertise in your industry, whether it's pharmaceuticals, metallurgy, or food processing. Their understanding of industry-specific standards and challenges is critical[4][9].

Evaluate Technological Capabilities

Look for manufacturers offering advanced technologies such as ultrasonic sieving, air classification, and multi-frequency vibration to handle your product's unique characteristics[1][3].

Consider Customization and Support

OEM manufacturers should provide flexible customization options and reliable after-sales support, including spare parts availability and technical assistance[3][6].

Conclusion

Powder sieve system manufacturers play a pivotal role in enhancing the quality and efficiency of powder processing across industries. By partnering with a reputable OEM manufacturer, you gain access to cutting-edge technology, customized solutions, and expert support that drive your business success. Whether you need vibratory sieves, ultrasonic systems, or air classifiers, selecting the right manufacturer ensures your production line operates at peak performance with consistent, high-quality output.

Frequently Asked Questions (FAQs)

Q1: What industries benefit most from powder sieve systems?

A1: Industries such as pharmaceuticals, food processing, metallurgy, chemicals, battery materials, and additive manufacturing benefit significantly from powder sieve systems due to their need for precise particle size control and contaminant removal[1][2][4].

Q2: How fine can powder sieve systems separate particles?

A2: Modern powder sieve systems can separate particles as fine as 10 microns with high yields, thanks to advanced technologies like ultrasonic sieving and multi-frequency vibration[1][2].

Q3: What is the advantage of ultrasonic sieving in powder processing?

A3: Ultrasonic sieving prevents screen blinding, increases throughput, and improves separation efficiency, especially for fine and cohesive powders[3][7].

Q4: Can powder sieve systems be customized for specific applications?

A4: Yes, OEM powder sieve system manufacturers offer customization in design, mesh size, and material handling to meet the unique requirements of different industries and products[3][6].

Q5: What maintenance features are important in powder sieve systems?

A5: Features like tool-free screen replacement, easy cleaning, low-energy motors, and durable construction are important to minimize downtime and reduce operational costs[9].

[1] https://elcanindustries.com/toll-processing/top-10-sieving-machines-screening-equipment-manufacturers-in-the-usa/

[2] https://elcanindustries.com/screening-technology/

[3] https://www.hksieve.com/industries/industries/powder-metal-manufacturing/

[4] https://www.russellfinex.com/en/news-and-events/sieving-powders/

[5] https://www.industrystock.com/en/companies/Process-Engineering/Screening-Technology/Sieve-System

[6] https://news.cnpowder.com.cn/70148.html

[7] https://2onelab.com/products/2sieve/

[8] https://www.sefar.com/zh/818/%E5%B7%A5%E4%B8%9A%E8%BF%87%E6%BB%A4/%E8%AE%BE%E5%A4%87.htm?Folder=7255318

[9] https://www.gea.com/zh/products/product-handling-systems/vibrating-sifters/sifters-for-powders/

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.