Content Menu

● Introduction

● 1. Ramseier Koatings Technologies Holdings Ltd.

>> Overview

>> Key Products

● 2. Quadro Engineering

>> Overview

>> Key Features

● 3. Kason Corporation

>> Overview

>> Key Products

● 4. Farleygreene

>> Overview

>> Key Features

● 5. Palamatic Process

>> Overview

>> Key Products

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What is a powder sieve?

>> 2. Why is powder sieving important in manufacturing?

>> 3. How does the FlexSift technology work?

>> 4. What industries benefit from powder sieving?

>> 5. How can I choose the right powder sieve for my needs?

Introduction

In the world of powder processing, the efficiency and quality of powder sieving equipment are paramount. This article explores the top powder sieve manufacturers and suppliers in Croatia, highlighting their offerings and expertise. Among these, Ramseier Koatings Technologies Holdings Ltd. stands out as a leader in the industry, providing innovative solutions for powder sieving and processing.

1. Ramseier Koatings Technologies Holdings Ltd.

Overview

Ramseier Koatings Technologies Holdings Ltd. is renowned for its advanced powder coating and sieving technologies. The company specializes in providing high-quality powder sieve systems that cater to various industries, including automotive, aerospace, and consumer goods. Their commitment to innovation and quality has made them a trusted partner for businesses looking to enhance their powder processing capabilities.

Key Products

- Powder Sieve Systems: Designed for efficient separation and classification of powders, ensuring high purity and quality.

- Electrostatic Spray Guns: Complementing their powder sieving solutions, these guns provide precise application of powder coatings.

- Automatic Spray Booth Systems: Integrated systems that enhance the efficiency of powder application and sieving processes.

2. Quadro Engineering

Overview

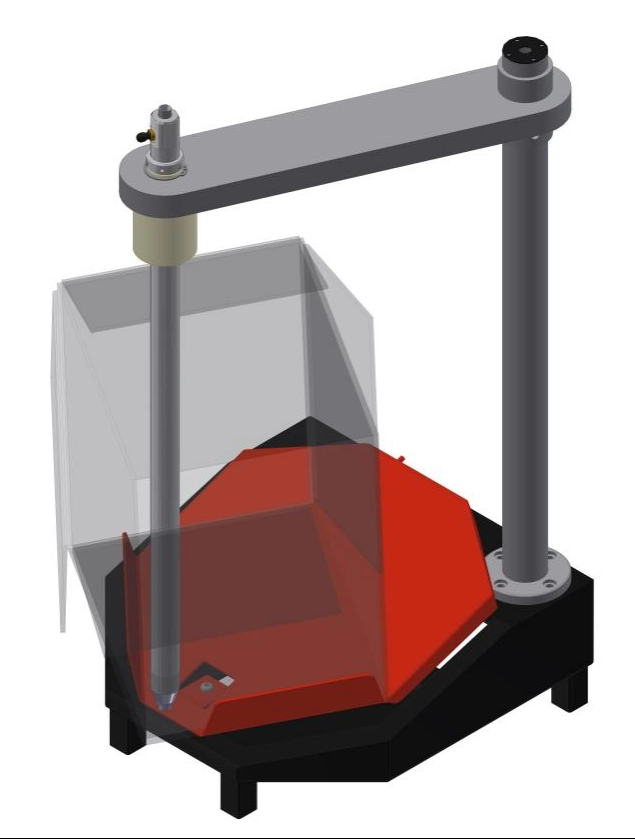

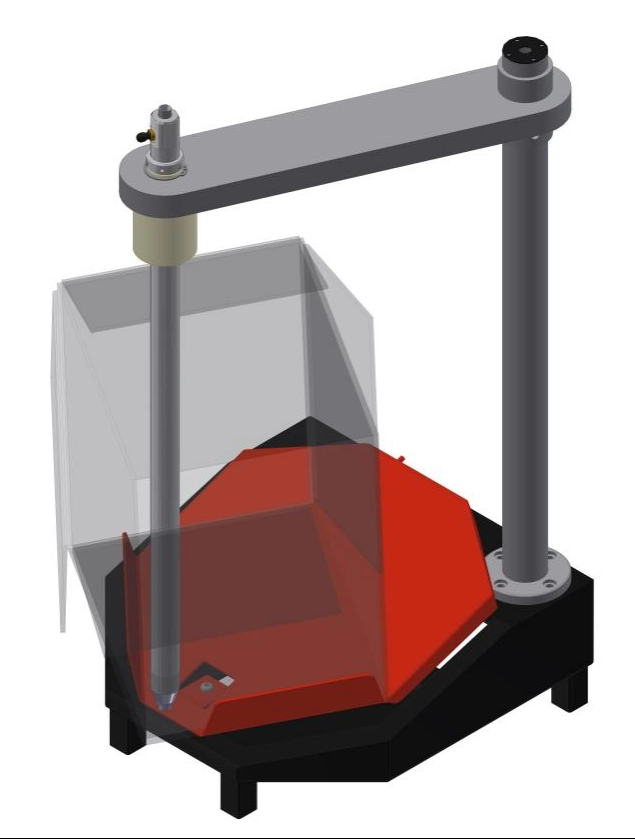

Quadro Engineering is a global leader in powder processing equipment, known for its innovative FlexSift technology. This equipment is designed for efficient powder sieving, ensuring that only uniform particles enter the processing stream.

Key Features

- High Capacity Screening: The FlexSift provides inline security screening and gentle deagglomeration, making it ideal for pharmaceutical and food industries.

- Versatile Applications: Suitable for various powders, including those used in nutraceuticals and food products.

3. Kason Corporation

Overview

Kason Corporation specializes in powder processing equipment, including static scalping sieves that effectively remove oversized particles from dry bulk solids.

Key Products

- CROSS-FLO Static Scalping Sieves: Economical units designed for continuous scalping applications.

- Batch and Continuous Powder Blending Equipment: Ensures uniformity in powder mixtures.

4. Farleygreene

Overview

Farleygreene is known for its Sievmaster range of sieving machines, which are designed for high efficiency in powder processing.

Key Features

- Automated Sieving Solutions: The Sievmaster 04-S is particularly noted for its automated metal powder sieving capabilities.

- High Throughput: Designed to handle large volumes of powder while maintaining quality.

5. Palamatic Process

Overview

Palamatic Process offers a wide range of industrial powder sieves, focusing on hygiene and efficiency in powder handling.

Key Products

- Vibrating Screens: These screens eliminate rejects with precision and are easy to maintain.

- Centrifugal Sieves: Designed for high efficiency in powder processing, suitable for various industries.

Conclusion

The powder sieve manufacturers and suppliers in Croatia are at the forefront of innovation in powder processing technology. Companies like Ramseier Koatings Technologies Holdings Ltd., Quadro Engineering, Kason Corporation, Farleygreene, and Palamatic Process are leading the way in providing high-quality, efficient, and reliable powder sieving solutions.

Frequently Asked Questions (FAQs)

1. What is a powder sieve?

A powder sieve is a device used to separate and classify powders based on particle size. It ensures that only particles of a certain size pass through, which is crucial for maintaining product quality.

2. Why is powder sieving important in manufacturing?

Powder sieving is essential for removing impurities and ensuring uniform particle size, which directly affects the quality of the final product in industries such as pharmaceuticals, food, and chemicals.

3. How does the FlexSift technology work?

The FlexSift technology uses a rotating basket to induce tangential velocity, allowing for efficient screening and deagglomeration of powders without damaging the particles.

4. What industries benefit from powder sieving?

Industries such as pharmaceuticals, food processing, chemicals, and cosmetics benefit significantly from powder sieving, as it ensures product quality and compliance with industry standards.

5. How can I choose the right powder sieve for my needs?

Choosing the right powder sieve depends on factors such as the type of powder, required throughput, and specific application needs. Consulting with manufacturers can help identify the best solution.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.