Content Menu

● Introduction

● Understanding Powder Coating

>> What is Powder Coating?

>> Advantages of Powder Coating

● The Role of Swinger Systems in Powder Coating

>> What are Swinger Systems?

>> Key Features of Swinger Systems

● Environmental Benefits of Swinger Systems

>> Waste Reduction

>> Energy Efficiency

>> Compliance with Environmental Standards

● Case Studies: Successful Implementation of Swinger Systems

>> Automotive Industry

>> Furniture Manufacturing

● Challenges and Considerations

>> Initial Investment

>> Training and Expertise

● Future Trends in Eco-Friendly Powder Coating

>> Innovations in Powder Formulations

>> Integration with Smart Technologies

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using swinger systems in powder coating?

>> 2. How do swinger systems help in reducing VOC emissions?

>> 3. Can swinger systems be used for all types of products?

>> 4. What are the environmental benefits of powder coating compared to traditional methods?

>> 5. What challenges might companies face when implementing swinger systems?

Introduction

In recent years, the demand for eco-friendly manufacturing processes has surged, particularly in the coatings industry. Among the various technologies that have emerged, swinger systems in powder coating have gained attention for their efficiency and sustainability. This article explores how these systems contribute to environmentally friendly powder coating processes, enhancing both performance and ecological responsibility.

Understanding Powder Coating

What is Powder Coating?

Powder coating is a dry finishing process that uses finely ground particles of pigment and resin, which are electrostatically charged and sprayed onto a surface. The coated item is then heated, causing the powder to melt and form a durable finish. This method is favored for its ability to produce a tough, high-quality finish while minimizing waste and environmental impact.

Advantages of Powder Coating

1. Reduced Volatile Organic Compounds (VOCs): Unlike traditional liquid coatings, powder coatings do not contain solvents that release VOCs into the atmosphere. This significantly lowers air pollution and contributes to a healthier environment.

2. High Transfer Efficiency: Powder coating systems can achieve transfer efficiencies of 90% or more, meaning that most of the powder applied adheres to the surface, reducing waste.

3. Durability: The resulting finish is more resistant to chipping, scratching, and fading compared to conventional paint, leading to longer-lasting products.

The Role of Swinger Systems in Powder Coating

What are Swinger Systems?

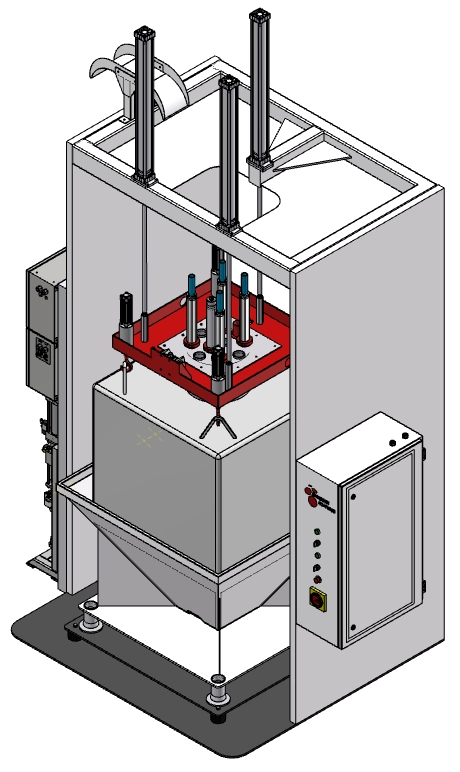

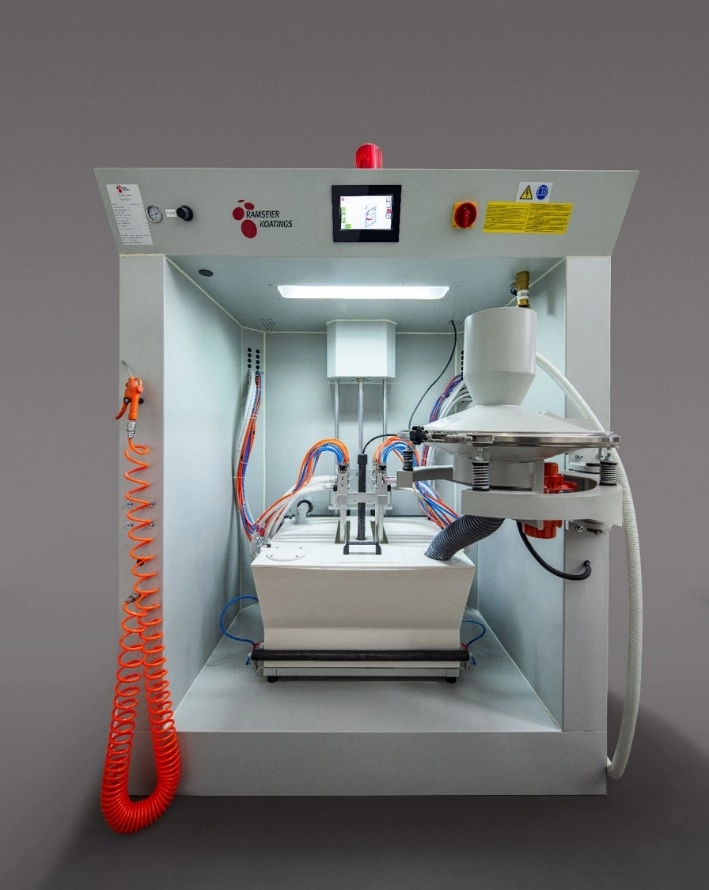

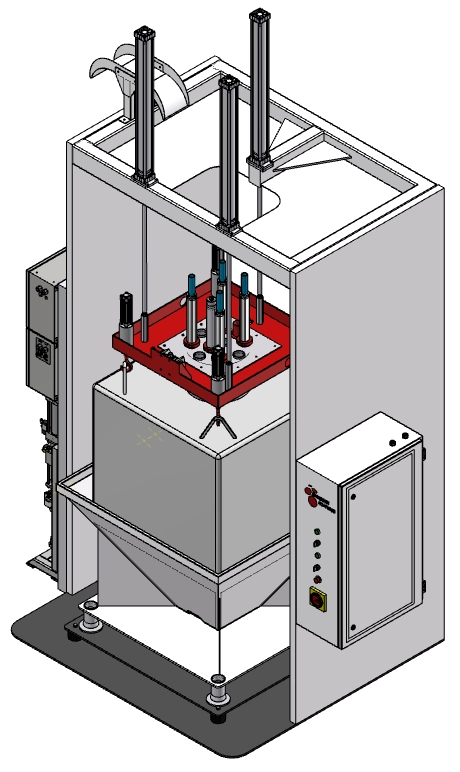

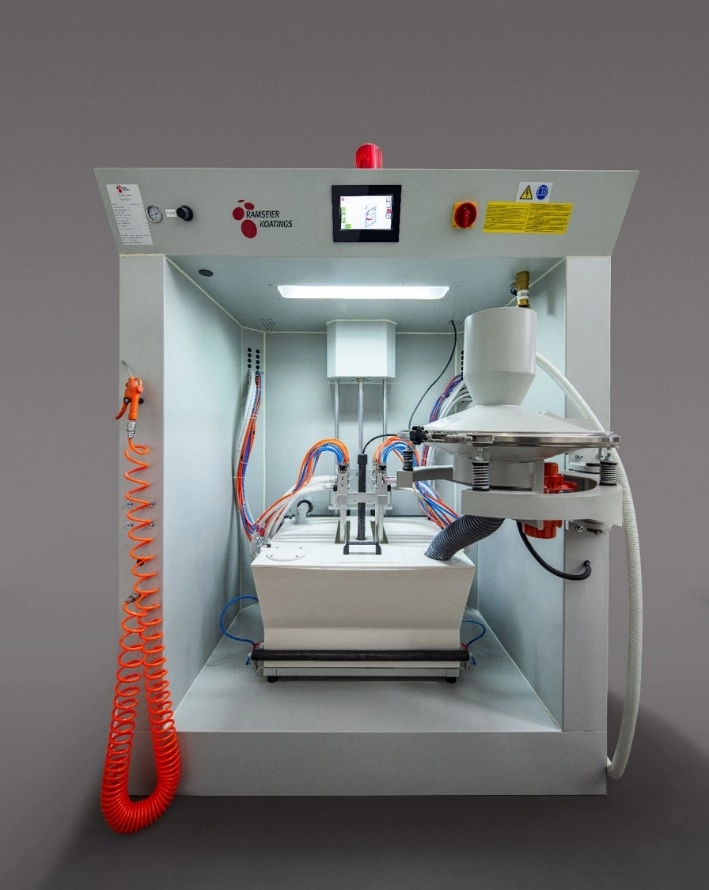

Swinger systems are advanced powder coating machines designed to enhance the application process. They utilize a swinging or rotating mechanism to ensure even coverage of complex shapes and surfaces. This technology is particularly beneficial for items with intricate geometries that are challenging to coat uniformly.

Key Features of Swinger Systems

1. Enhanced Coverage: The swinging motion allows the powder to reach recessed areas and corners that static spray guns might miss. This results in a more uniform coating and reduces the need for manual touch-ups.

2. Automation and Precision: Many swinger systems are equipped with automated controls that optimize the spraying process. This precision minimizes overspray and ensures that the right amount of powder is applied, further reducing waste.

3. Flexibility: Swinger systems can adapt to various product sizes and shapes, making them suitable for a wide range of applications, from small components to large industrial parts.

Environmental Benefits of Swinger Systems

Waste Reduction

One of the most significant advantages of swinger systems is their ability to minimize waste. By improving transfer efficiency and reducing overspray, these systems help manufacturers conserve materials and lower production costs. The ability to reclaim and reuse oversprayed powder further enhances sustainability.

Energy Efficiency

Swinger systems contribute to energy savings in several ways. The curing process for powder coatings typically requires lower temperatures compared to liquid coatings, which means less energy consumption. Additionally, the automation in swinger systems can optimize the curing cycle, further reducing energy use.

Compliance with Environmental Standards

As environmental regulations become stricter, industries are increasingly required to adopt sustainable practices. Swinger systems, by virtue of their design and operation, help companies comply with these regulations. The reduction of VOC emissions and waste aligns with global sustainability goals, making these systems an attractive option for eco-conscious manufacturers.

Case Studies: Successful Implementation of Swinger Systems

Automotive Industry

In the automotive sector, where durability and aesthetics are paramount, swinger systems have been successfully implemented to enhance powder coating processes. Manufacturers report improved finish quality and reduced waste, leading to significant cost savings and a smaller environmental footprint.

Furniture Manufacturing

The furniture industry has also benefited from the adoption of swinger systems. By achieving consistent finishes on complex designs, manufacturers can reduce rework and improve customer satisfaction. The eco-friendly nature of powder coating aligns with the growing consumer demand for sustainable products.

Challenges and Considerations

Initial Investment

While swinger systems offer numerous benefits, the initial investment can be substantial. Companies must weigh the long-term savings and environmental benefits against the upfront costs of purchasing and installing these systems.

Training and Expertise

Implementing advanced technology like swinger systems requires skilled personnel. Companies may need to invest in training to ensure that their workforce can operate and maintain these systems effectively.

Future Trends in Eco-Friendly Powder Coating

Innovations in Powder Formulations

As the demand for sustainable practices grows, manufacturers are developing new powder formulations that are even more eco-friendly. These include low-VOC and non-toxic options that further reduce environmental impact.

Integration with Smart Technologies

The future of powder coating may see increased integration with smart technologies, such as IoT devices that monitor and optimize the coating process in real-time. This could lead to even greater efficiencies and sustainability in manufacturing.

Conclusion

Swinger systems represent a significant advancement in the powder coating industry, offering numerous benefits that contribute to eco-friendly manufacturing processes. By enhancing coverage, reducing waste, and improving energy efficiency, these systems not only meet the demands of modern production but also align with global sustainability goals. As industries continue to prioritize environmental responsibility, the adoption of swinger systems in powder coating is likely to grow, paving the way for a more sustainable future.

Frequently Asked Questions

1. What are the main advantages of using swinger systems in powder coating?

Swinger systems provide enhanced coverage, reduce waste through high transfer efficiency, and improve energy efficiency during the curing process.

2. How do swinger systems help in reducing VOC emissions?

Swinger systems utilize powder coatings, which are inherently free of solvents that release VOCs, thus contributing to lower air pollution.

3. Can swinger systems be used for all types of products?

Yes, swinger systems are versatile and can be adapted to coat a wide range of product sizes and shapes, making them suitable for various industries.

4. What are the environmental benefits of powder coating compared to traditional methods?

Powder coating generates less waste, has higher transfer efficiency, and emits fewer harmful chemicals, making it a more sustainable option than traditional liquid coatings.

5. What challenges might companies face when implementing swinger systems?

Challenges include the initial investment cost and the need for skilled personnel to operate and maintain the systems effectively.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.