Content Menu

● Introduction

● Understanding Reciprocators in Spray Booth Systems

>> What Is a Reciprocator?

>> How Does a Reciprocator Work?

● Operational Benefits of Reciprocators

>> Enhanced Coating Uniformity

>> Increased Production Speed

>> Reduced Material Waste

● Quality Improvements Enabled by Reciprocators

>> Superior Surface Finish

>> Consistency Across Batches

>> Compatibility with Various Coating Materials

● Efficiency and Cost-Effectiveness

>> Minimization of Labor Costs

>> Energy Savings

>> Decreased Maintenance Requirements

● Practical Applications of Reciprocators in Industry

>> Automotive Manufacturing

>> Furniture Finishing

>> Electronics and Appliance Painting

● Integration and Customization

>> Programmable Motion Patterns

>> Synchronization with Other Systems

>> Scalability and Flexibility

● Environmental and Safety Advantages

>> Reduction in Volatile Organic Compounds (VOCs)

>> Improved Workplace Safety

● Challenges and Considerations

>> Initial Investment Costs

>> Maintenance Expertise

● Summary of Benefits

● Frequently Asked Questions (FAQs)

>> 1. What types of spray booth systems are compatible with reciprocators?

>> 2. How does a reciprocator improve paint application compared to manual spraying?

>> 3. Can reciprocators handle different paint viscosities and formulas?

>> 4. What maintenance is required for reciprocators?

>> 5. Are reciprocators suitable for small-scale manufacturing?

Introduction

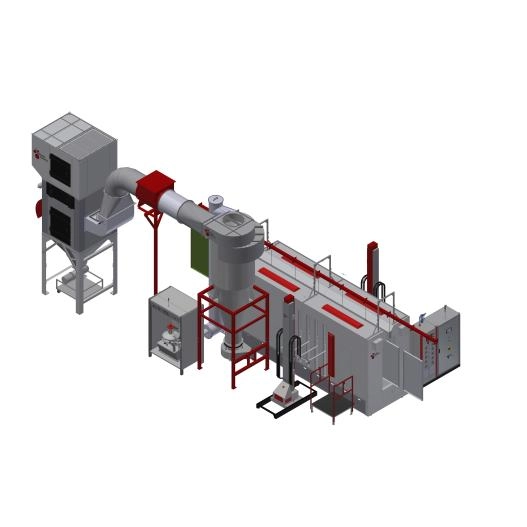

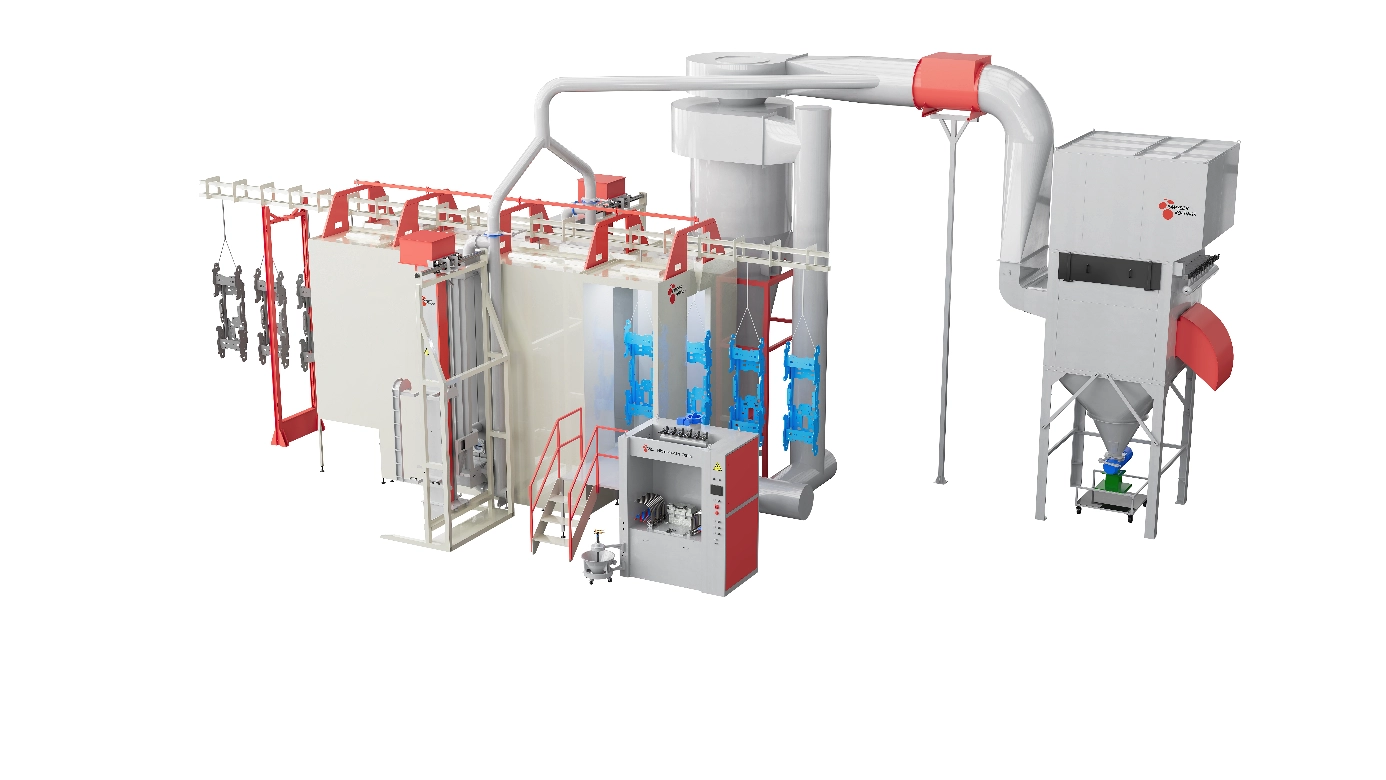

In modern industrial painting and coating processes, achieving consistent, high-quality finishes is paramount. Automatic spray booth systems have revolutionized production efficiency, especially in sectors like automotive, furniture, and electronics manufacturing. A crucial component that enhances these systems' effectiveness is the reciprocator. Reciprocators, also known as reciprocating spray devices, create controlled, repetitive motion to ensure even and precise coating coverage. This article explores the numerous benefits of using reciprocators in automatic spray booth systems, detailing their operational advantages, efficiency improvements, quality enhancements, and long-term cost benefits.

Understanding Reciprocators in Spray Booth Systems

What Is a Reciprocator?

A reciprocator is a mechanical device that moves spray guns or nozzles back and forth in a linear or vertical motion. It is integrated into automatic spray booth systems to control the spraying action, enabling uniform application of paint or coating materials on parts or surfaces.

How Does a Reciprocator Work?

Reciprocators are typically driven by electric motors, pneumatic actuators, or hydraulic systems to produce smooth, consistent movement patterns. The speed, stroke length, and motion patterns are adjustable to accommodate various product sizes and coating requirements. This precise control allows spray guns to maintain an optimal distance and angle from the target surface throughout the operation.

Operational Benefits of Reciprocators

Enhanced Coating Uniformity

One of the primary advantages of reciprocators is the uniform film thickness they achieve. Because the spray gun moves consistently across the surface, it prevents common issues such as over-application and runs. This uniform film ensures better drying characteristics, adhesion, and overall finish quality.

Increased Production Speed

The automated and consistent movement of reciprocators allows high-speed operation without compromising coating quality. This speeds up the painting process compared to manual or semi-automatic systems, reducing cycle times and boosting throughput in high-volume production environments.

Reduced Material Waste

Reciprocators enable precise spray patterns and targeted application, thus minimizing overspray and reducing paint consumption. Less waste translates to lower material costs and a reduction in environmental impact due to less paint volatilization and waste disposal.

Quality Improvements Enabled by Reciprocators

Superior Surface Finish

Reciprocators provide smooth and consistent coating layers that minimize defects like sags, runs, or orange peel textures. The controlled motion ensures even deposition of paint particles, resulting in superior aesthetic and functional surface finishes.

Consistency Across Batches

In mass production, maintaining consistent quality between batches is vital. Reciprocators deliver repeatable and predictable spray motions, greatly reducing lot-to-lot variability. This consistency helps manufacturing facilities meet rigorous quality standards and customer expectations.

Compatibility with Various Coating Materials

Reciprocators are versatile and can handle different types of coating materials including paints, primers, lacquers, and powders. They can be programmed to adapt to the viscosity and application parameters of each coating, ensuring optimal results across a wide product range.

Efficiency and Cost-Effectiveness

Minimization of Labor Costs

Automating the spray application process with reciprocators reduces dependence on manual labor. Fewer operators are needed to monitor and control the process, which lowers labor expenses while decreasing operator fatigue and error.

Energy Savings

Modern reciprocators use energy-efficient motors and controls to optimize movement. Automated motion reduces the need for excessive spray passes, optimizing energy consumption related to paint drying ovens and spraying equipment.

Decreased Maintenance Requirements

Reciprocators are designed for durability and low-maintenance operation. Their simplified mechanical design and programmable controls require less frequent repairs and recalibrations compared to manual spray methods, reducing downtime and maintenance expenses.

Practical Applications of Reciprocators in Industry

Automotive Manufacturing

In automotive painting lines, reciprocators ensure that vehicle bodies receive uniform coats of paint at high speeds. This consistency improves corrosion resistance and aesthetic appeal, critical factors in automotive quality.

Furniture Finishing

Furniture manufacturers use reciprocators for applying clear coats, stains, and paints evenly on large panels and complex shapes. Reciprocators help achieve smooth finishes that are essential for high-end furniture products.

Electronics and Appliance Painting

For electronics and appliances, coating uniformity is vital to product durability and appearance. Reciprocators provide precise spray control to delicately handle sensitive surfaces without waste or defects.

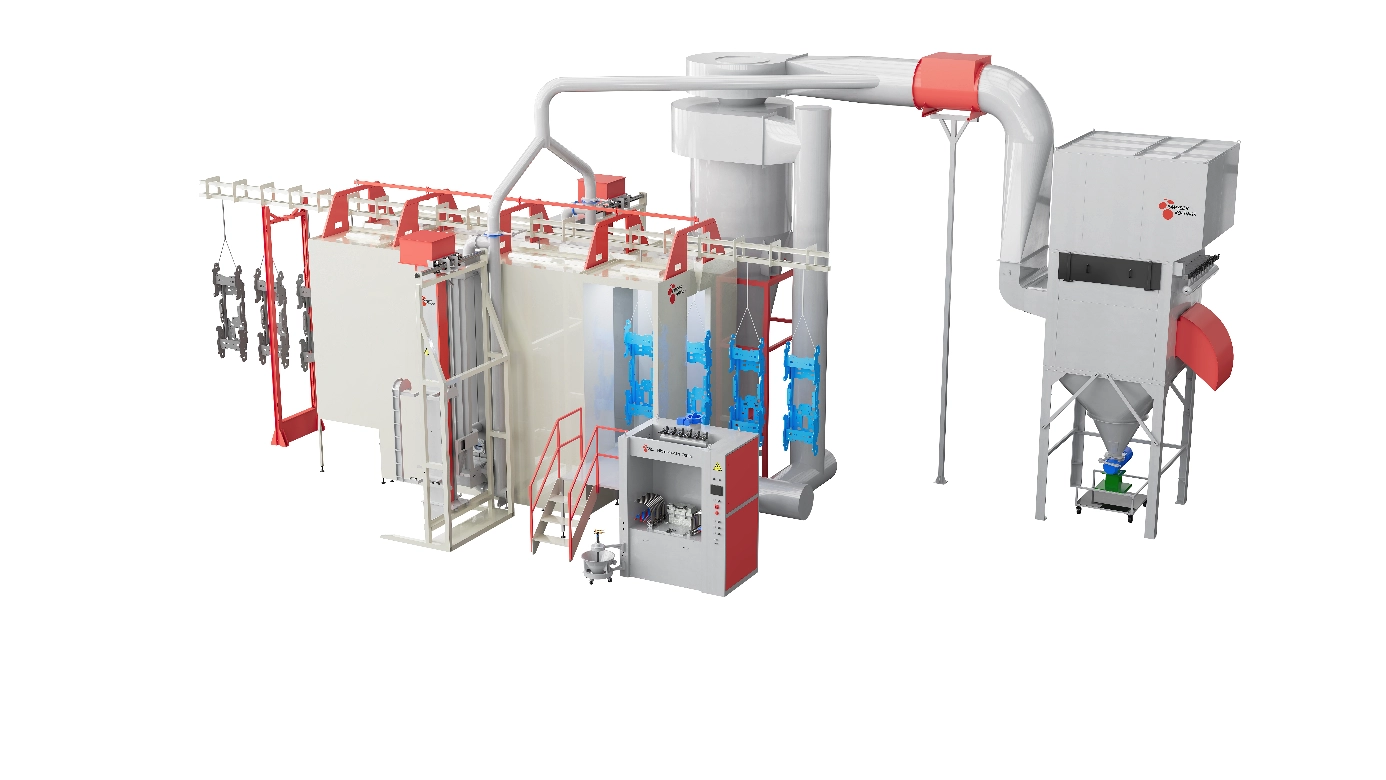

Integration and Customization

Programmable Motion Patterns

Many reciprocators come with software that allows customization of spray patterns, speed, and stroke lengths. This programmability ensures adaptability for different production lines or product shapes without hardware changes.

Synchronization with Other Systems

Reciprocators integrate seamlessly with conveyor systems, robotic arms, and drying ovens. This synchronization ensures efficient workflow and maximizes throughput in fully automated production setups.

Scalability and Flexibility

For manufacturers with fluctuating production demands or varied product lines, reciprocators offer scalable solutions. They can be configured to cover small batches or mass production runs with minimal setup changes.

Environmental and Safety Advantages

Reduction in Volatile Organic Compounds (VOCs)

By optimizing coating application, reciprocators reduce overspray and evaporation, helping companies meet environmental regulations for VOC emissions.

Improved Workplace Safety

Automated reciprocators limit worker exposure to hazardous paint fumes and airborne particulates. This leads to healthier working environments and compliance with occupational safety standards.

Challenges and Considerations

Initial Investment Costs

Although reciprocators offer cost savings over time, the upfront investment in equipment and system integration can be significant. Manufacturers should conduct cost-benefit analyses based on production scale and long-term savings.

Maintenance Expertise

Operators need training to handle maintenance and programming of reciprocators. However, modern reciprocators often come with user-friendly interfaces to minimize learning curves.

Summary of Benefits

- Achieve consistent, uniform coating application

- Increase production speeds and output

- Reduce material waste and lower operational costs

- Enhance surface finish quality and batch consistency

- Minimize labor costs and operator errors

- Save energy and maintenance expenses

- Adapt to various coating materials and product types

- Improve workplace safety and environmental compliance

Frequently Asked Questions (FAQs)

1. What types of spray booth systems are compatible with reciprocators?

Reciprocators can be integrated into a wide range of automatic spray booth systems, including conveyorized, batch, robotic, and manual hybrid setups. Compatibility depends on the specific spray booth design and production requirements.

2. How does a reciprocator improve paint application compared to manual spraying?

Reciprocators provide consistent, repeatable motion that avoids human error, ensuring uniform paint thickness, reducing overspray, and improving overall finish quality—outcomes difficult to achieve with manual spraying.

3. Can reciprocators handle different paint viscosities and formulas?

Yes, reciprocators often feature adjustable speed and stroke settings to accommodate different coating materials, from thin lacquers to thicker paints or primers, ensuring optimal application for each type.

4. What maintenance is required for reciprocators?

Maintenance typically involves routine lubrication, periodic calibration, and cleaning of moving parts. Many modern reciprocators have diagnostics and self-calibration features to simplify upkeep.

5. Are reciprocators suitable for small-scale manufacturing?

Absolutely. While reciprocators excel in high-volume environments, smaller-scale manufacturers benefit from improved finish quality and efficiency, especially with programmable and customizable units designed for flexibility.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.