Content Menu

● Understanding Powder Coating

>> What is Powder Coating?

>> The Role of Electrostatics in Powder Coating

● Advantages of Manual Electrostatic Spray Guns

>> Enhanced Control and Precision

>>> Customization of Spray Patterns

>> Improved Powder Transfer Efficiency

>> Versatility in Application

>>> Spot Repairs and Touch-Ups

● The Science Behind Powder Adhesion

>> Electrostatic Charge Dynamics

>>> Factors Affecting Adhesion

>> Surface Preparation

● Practical Applications of Manual Electrostatic Spray Guns

>> Automotive Industry

>> Furniture Manufacturing

>> Appliance Coating

● Conclusion

>> Frequently Asked Questions

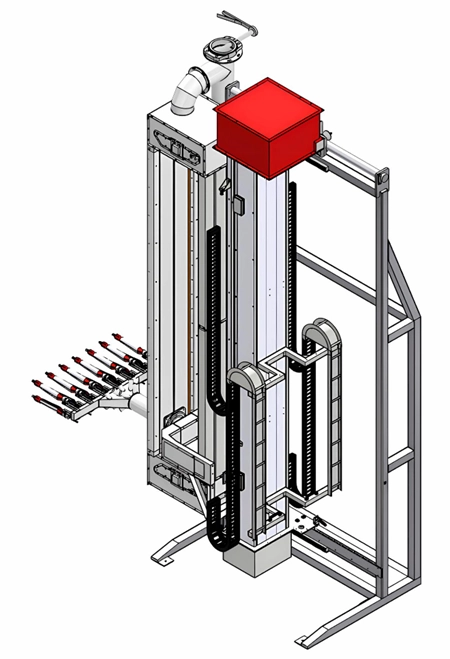

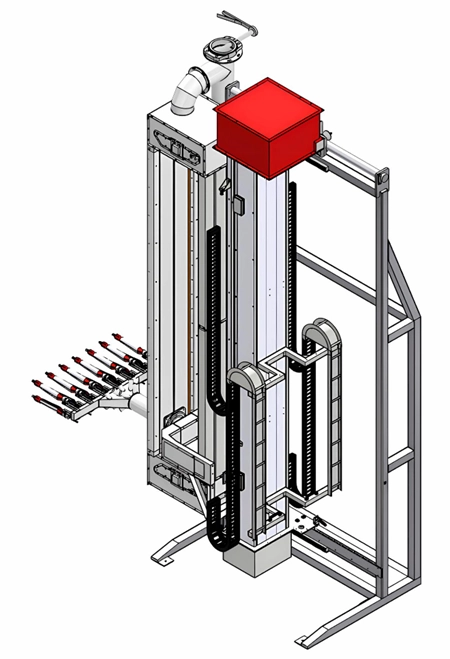

Powder coating has become a preferred method for finishing metal surfaces due to its durability, efficiency, and environmental benefits. Among the various techniques available, manual electrostatic spray guns stand out for their superior powder adhesion capabilities. This article explores the reasons why powder adhesion is better with manual electrostatic spray guns, delving into the technology, advantages, and practical applications of this method.

Understanding Powder Coating

What is Powder Coating?

Powder coating is a dry finishing process that involves applying a fine powder to a substrate, typically metal. The powder is composed of resin and pigment, which, when heated, melt and form a solid, durable coating. This method is widely used in various industries, including automotive, furniture, and appliances, due to its ability to provide a tough, protective finish.

The Role of Electrostatics in Powder Coating

Electrostatic powder coating utilizes an electric charge to attract the powder particles to the grounded workpiece. This process enhances the efficiency of the coating application, reducing overspray and ensuring a more uniform finish. The electrostatic charge causes the powder particles to adhere better to the surface, which is crucial for achieving a high-quality coating.

Advantages of Manual Electrostatic Spray Guns

Enhanced Control and Precision

One of the primary advantages of manual electrostatic spray guns is the level of control they offer to the operator. Unlike automated systems, manual guns allow for precise adjustments in spray patterns, flow rates, and distances from the workpiece. This flexibility is particularly beneficial when coating complex shapes or intricate designs, where uniform coverage is essential.

Customization of Spray Patterns

Manual electrostatic spray guns enable operators to customize the spray pattern according to the specific requirements of the job. This customization is vital for achieving optimal adhesion, especially in hard-to-reach areas or on surfaces with varying geometries. The ability to adjust the nozzle and spray angle ensures that the powder is evenly distributed, enhancing adhesion.

Improved Powder Transfer Efficiency

Manual electrostatic spray guns are designed to maximize powder transfer efficiency. The electrostatic charge applied to the powder particles helps them adhere to the surface more effectively, reducing waste and improving the overall efficiency of the coating process. This efficiency is particularly important in high-volume production environments, where minimizing material waste can lead to significant cost savings.

Versatility in Application

Manual electrostatic spray guns are versatile tools that can be used for a wide range of applications. They are suitable for both large-scale production and small batch jobs, making them ideal for various industries. Whether coating large metal structures or intricate components, manual guns can adapt to the specific needs of the project.

Spot Repairs and Touch-Ups

In addition to full coatings, manual electrostatic spray guns are excellent for spot repairs and touch-ups. The operator can easily target specific areas that require additional coating, ensuring that the finish remains consistent and high-quality. This capability is particularly valuable in industries where aesthetics and durability are paramount.

The Science Behind Powder Adhesion

Electrostatic Charge Dynamics

The effectiveness of manual electrostatic spray guns in enhancing powder adhesion can be attributed to the dynamics of electrostatic charge. When the powder particles are charged, they are attracted to the grounded workpiece, creating a strong bond. This attraction is influenced by several factors, including the type of powder, the voltage applied, and the distance between the gun and the surface.

Factors Affecting Adhesion

1. Powder Composition: Different powders have varying electrical properties, which can affect their adhesion capabilities. Selecting the right powder for the application is crucial for achieving optimal results.

2. Voltage Settings: The voltage applied to the spray gun can significantly impact the adhesion of the powder. Higher voltages can enhance the attraction between the powder and the surface, but they must be carefully controlled to avoid issues such as overspray or uneven coating.

3. Distance from the Workpiece: The distance between the spray gun and the workpiece also plays a critical role in adhesion. Maintaining an optimal distance ensures that the powder particles have sufficient time to charge and adhere effectively.

Surface Preparation

Proper surface preparation is essential for maximizing powder adhesion. The substrate must be clean, free of contaminants, and appropriately pre-treated to promote bonding. Techniques such as chemical cleaning, sandblasting, or phosphating can enhance the surface's properties, allowing for better adhesion of the powder coating.

Practical Applications of Manual Electrostatic Spray Guns

Automotive Industry

In the automotive industry, manual electrostatic spray guns are widely used for coating car bodies, frames, and components. The ability to achieve a high-quality finish with excellent adhesion is crucial for durability and aesthetics. Manual guns allow for precise application, ensuring that every part receives the necessary coating.

Furniture Manufacturing

Furniture manufacturers benefit from the versatility and control offered by manual electrostatic spray guns. These guns enable the application of various colors and finishes, allowing for customization and creativity in design. The improved adhesion ensures that the coatings withstand wear and tear, maintaining the furniture's appearance over time.

Appliance Coating

Appliance manufacturers utilize manual electrostatic spray guns to coat metal surfaces of refrigerators, ovens, and other appliances. The durability and resistance to chipping and scratching provided by powder coatings are essential for these products, making manual guns an ideal choice for achieving high-quality finishes.

Conclusion

Manual electrostatic spray guns offer significant advantages in powder adhesion compared to other coating methods. Their ability to provide enhanced control, improved transfer efficiency, and versatility makes them a preferred choice in various industries. By understanding the science behind powder adhesion and the practical applications of these guns, manufacturers can achieve superior finishes that meet the demands of modern production.

Frequently Asked Questions

1. What is the main advantage of using manual electrostatic spray guns?

- The main advantage is the enhanced control and precision they offer, allowing for customized spray patterns and improved powder transfer efficiency.

2. How does electrostatic charge improve powder adhesion?

- Electrostatic charge attracts powder particles to the grounded workpiece, creating a strong bond that enhances adhesion and reduces overspray.

3. Can manual electrostatic spray guns be used for spot repairs?

- Yes, they are excellent for spot repairs and touch-ups, allowing operators to target specific areas that require additional coating.

4. What factors affect powder adhesion in electrostatic spray applications?

- Factors include powder composition, voltage settings, and the distance from the workpiece.

5. In which industries are manual electrostatic spray guns commonly used?

- They are commonly used in the automotive, furniture manufacturing, and appliance coating industries.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.