Content Menu

● Introduction

● 1. Ramseier Koatings Technologies Holdings Ltd.

>> Overview

>> Product Offerings

>> Why Choose Ramseier?

● 2. Colo International

>> Key Features

● 3. Graco Inc.

>> Advantages of Graco Spray Guns

● 4. Binks

>> Product Highlights

● 5. Ransburg

>> Unique Selling Points

● Benefits of Using Electrostatic Spray Guns

>> 1. Improved Transfer Efficiency

>> 2. Enhanced Finish Quality

>> 3. Environmentally Friendly

>> 4. Versatility

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What is an electrostatic spray gun?

>> 2. Why should I choose a manual electrostatic spray gun?

>> 3. How do electrostatic spray guns reduce waste?

>> 4. Can electrostatic spray guns be used with all types of coatings?

>> 5. What are the benefits of using Ramseier Koatings products?

Introduction

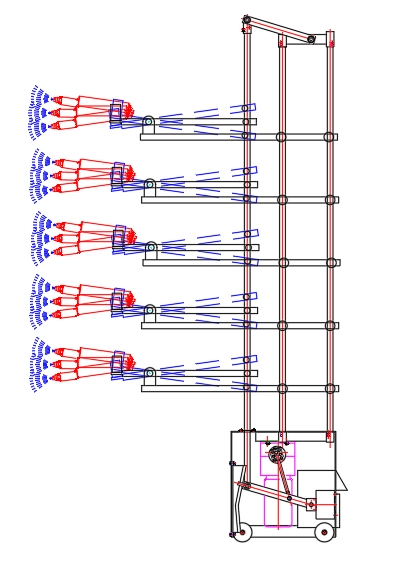

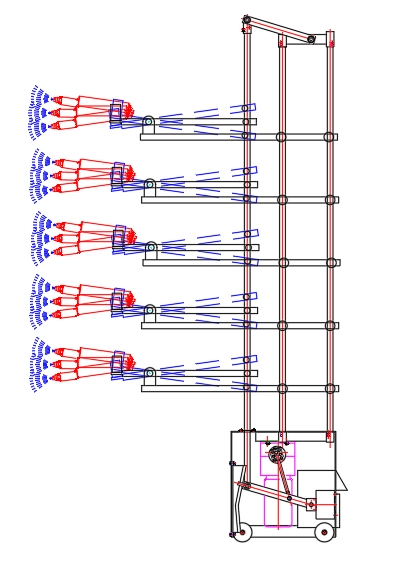

In the world of industrial coating, electrostatic spray guns have revolutionized the way coatings are applied. These tools not only enhance the quality of the finish but also improve efficiency and reduce waste. In Nepal, several manufacturers and suppliers are leading the charge in providing high-quality manual electrostatic spray guns. This article will explore the top manufacturers and suppliers, with a special focus on Ramseier Koatings Technologies Holdings Ltd., a prominent player in the industry.

1. Ramseier Koatings Technologies Holdings Ltd.

Overview

Ramseier Koatings Technologies Holdings Ltd. is a leading manufacturer of electrostatic spray guns in Nepal. With a commitment to quality and innovation, they offer a range of products designed to meet the needs of various industries. Their manual electrostatic spray guns are known for their precision and efficiency, making them a preferred choice for many businesses.

Product Offerings

- Manual Electrostatic Spray Guns: Designed for ease of use and high transfer efficiency.

- Control Units: Advanced control systems that enhance the performance of spray guns.

- Powder Coating Equipment: Comprehensive solutions for powder coating applications.

Why Choose Ramseier?

- Quality Assurance: Rigorous testing ensures that every product meets high standards.

- Customer Support: Dedicated support team to assist clients with their needs.

- Innovative Technology: Continuous investment in research and development to stay ahead in the market.

2. Colo International

Colo International is another significant player in the electrostatic spray gun market in Nepal. They specialize in providing a wide range of spray guns that cater to different industrial needs.

Key Features

- High Transfer Efficiency: Their spray guns are designed to minimize paint waste.

- Durability: Built to withstand the rigors of industrial use.

- Versatility: Suitable for various applications, including automotive and furniture coatings.

3. Graco Inc.

Graco Inc. is a globally recognized brand known for its high-quality spray equipment. Their electrostatic spray guns are widely used in Nepal for various applications.

Advantages of Graco Spray Guns

- Advanced Technology: Incorporates the latest technology for optimal performance.

- Wide Range of Products: Offers both manual and automatic spray guns.

- Excellent Finish Quality: Ensures a smooth and even coating.

4. Binks

Binks is a well-established name in the spray gun industry, providing reliable and efficient electrostatic spray guns.

Product Highlights

- Robust Design: Built to last, even in demanding environments.

- User-Friendly: Easy to operate, making them suitable for both professionals and beginners.

- Comprehensive Solutions: Offers a complete range of finishing solutions.

5. Ransburg

Ransburg specializes in electrostatic finishing systems and is known for its innovative approach to spray technology.

Unique Selling Points

- High Transfer Efficiency: Reduces overspray and waste.

- Custom Solutions: Tailors products to meet specific customer requirements.

- Strong Industry Presence: A trusted name in various sectors, including automotive and industrial coatings.

Benefits of Using Electrostatic Spray Guns

1. Improved Transfer Efficiency

Electrostatic spray guns utilize electrical charges to attract paint particles to the surface being coated. This results in a higher transfer efficiency compared to conventional spray methods, reducing paint waste and saving costs.

2. Enhanced Finish Quality

The electrostatic process allows for a more even application of paint, leading to a superior finish. This is particularly important in industries where aesthetics are crucial.

3. Environmentally Friendly

By reducing overspray and waste, electrostatic spray guns contribute to a more sustainable coating process. They also help in minimizing volatile organic compounds (VOCs) released into the atmosphere.

4. Versatility

These spray guns can be used with a variety of coatings, including water-based and solvent-based paints, making them suitable for diverse applications.

Conclusion

In conclusion, the demand for manual electrostatic spray guns in Nepal is on the rise, driven by the need for efficient and high-quality coating solutions. Companies like Ramseier Koatings Technologies Holdings Ltd., Colo International, Graco Inc., Binks, and Ransburg are at the forefront of this industry, providing innovative products that meet the needs of various sectors. As businesses continue to seek out the best solutions for their coating needs, these manufacturers will play a crucial role in shaping the future of the industry.

Frequently Asked Questions (FAQs)

1. What is an electrostatic spray gun?

An electrostatic spray gun is a device that uses electrical charges to apply paint or coatings to surfaces, resulting in improved transfer efficiency and finish quality.

2. Why should I choose a manual electrostatic spray gun?

Manual electrostatic spray guns offer greater control and flexibility, making them ideal for detailed work and applications where precision is essential.

3. How do electrostatic spray guns reduce waste?

By using electrical charges to attract paint particles to the surface, electrostatic spray guns minimize overspray and ensure that more paint reaches the intended area.

4. Can electrostatic spray guns be used with all types of coatings?

Yes, electrostatic spray guns can be used with a variety of coatings, including water-based and solvent-based paints.

5. What are the benefits of using Ramseier Koatings products?

Ramseier Koatings products are known for their quality, innovative technology, and excellent customer support, making them a reliable choice for businesses in need of electrostatic spray guns.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.