Content Menu

● Introduction

● Overview of Electrostatic Spray Guns

>> Benefits of Using Electrostatic Spray Guns

● Leading Manufacturers of Electrostatic Spray Guns in Liechtenstein

>> 1. Ramseier Koatings Technologies Holdings Ltd.

>> 2. Graco Inc.

>> 3. Ransburg

>> 4. Binks

>> 5. Wagner

● Choosing the Right Electrostatic Spray Gun

>> 1. Application Type

>> 2. Transfer Efficiency

>> 3. Ease of Use

>> 4. Compatibility with Coatings

● Frequently Asked Questions (FAQs)

>> 1. What is an electrostatic spray gun?

>> 2. How does an electrostatic spray gun work?

>> 3. What are the advantages of using electrostatic spray guns?

>> 4. Can electrostatic spray guns be used with all types of coatings?

>> 5. How do I maintain my electrostatic spray gun?

● Conclusion

Introduction

In the world of industrial coating, electrostatic spray guns have revolutionized the way surfaces are coated, providing superior finish quality and efficiency. This article explores the top manufacturers and suppliers of automatic electrostatic spray guns in Liechtenstein, with a special focus on Ramseier Koatings Technologies Holdings Ltd., a leader in the field. We will delve into the features, benefits, and applications of these innovative tools, while also addressing common questions related to electrostatic spray guns.

Overview of Electrostatic Spray Guns

Electrostatic spray guns utilize an electric charge to attract paint particles to the surface being coated. This technology not only enhances the quality of the finish but also reduces overspray and material waste, making it an environmentally friendly option for various industries.

Benefits of Using Electrostatic Spray Guns

1. High Transfer Efficiency: Electrostatic spray guns can achieve transfer efficiencies of up to 90%, meaning less paint is wasted during the application process.

2. Improved Finish Quality: The electrostatic charge helps the paint adhere better to the surface, resulting in a smoother and more uniform finish.

3. Reduced VOC Emissions: By minimizing overspray, electrostatic spray guns contribute to lower volatile organic compound (VOC) emissions, making them a greener choice for manufacturers.

4. Versatility: These guns can be used with a variety of coatings, including waterborne, solvent-based, and powder coatings.

Leading Manufacturers of Electrostatic Spray Guns in Liechtenstein

1. Ramseier Koatings Technologies Holdings Ltd.

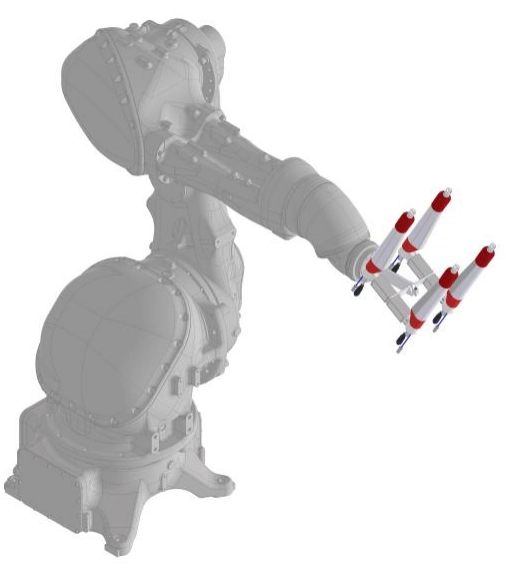

Ramseier Koatings Technologies Holdings Ltd. stands out as a premier manufacturer of electrostatic spray guns in Liechtenstein. Known for their commitment to quality and innovation, Ramseier offers a range of products designed for various industrial applications. Their electrostatic spray guns are engineered for high performance, ensuring optimal coating results.

2. Graco Inc.

Graco is another key player in the electrostatic spray gun market. Their Pro Xp Auto electrostatic spray guns are renowned for their reliability and efficiency. Graco's products are widely used in automotive and industrial applications, providing excellent finish quality and transfer efficiency.

3. Ransburg

Ransburg, a brand under Carlisle Fluid Technologies, specializes in electrostatic finishing equipment. Their electrostatic spray guns are designed to deliver superior atomization and transfer efficiency, making them a popular choice among manufacturers seeking high-quality finishes.

4. Binks

Binks is known for its extensive range of spray equipment, including electrostatic spray guns. Their products are designed to meet the needs of various industries, providing reliable performance and excellent coating results.

5. Wagner

Wagner is a global leader in coating technology, offering a variety of electrostatic spray guns that cater to different applications. Their products are designed for ease of use and high efficiency, making them a preferred choice for many manufacturers.

Choosing the Right Electrostatic Spray Gun

When selecting an electrostatic spray gun, consider the following factors:

1. Application Type

Different applications may require specific types of spray guns. For instance, automotive coatings may need guns that can handle high viscosity paints, while furniture finishing might require guns that provide a fine mist.

2. Transfer Efficiency

Look for guns that offer high transfer efficiency to minimize waste and reduce costs. Guns with efficiencies above 80% are generally considered good.

3. Ease of Use

Choose a spray gun that is user-friendly and easy to maintain. Features like adjustable settings and ergonomic designs can enhance the user experience.

4. Compatibility with Coatings

Ensure that the spray gun is compatible with the types of coatings you plan to use, whether they are solvent-based, waterborne, or powder coatings.

Frequently Asked Questions (FAQs)

1. What is an electrostatic spray gun?

An electrostatic spray gun is a device that uses an electric charge to attract paint particles to a surface, resulting in a more efficient and effective coating process.

2. How does an electrostatic spray gun work?

The gun charges the paint particles as they exit the nozzle, which are then attracted to the grounded surface, reducing overspray and improving transfer efficiency.

3. What are the advantages of using electrostatic spray guns?

The main advantages include high transfer efficiency, improved finish quality, reduced VOC emissions, and versatility in application.

4. Can electrostatic spray guns be used with all types of coatings?

Most electrostatic spray guns can be used with a variety of coatings, including waterborne, solvent-based, and powder coatings, but it's essential to check compatibility.

5. How do I maintain my electrostatic spray gun?

Regular maintenance includes cleaning the gun after each use, checking for clogs, and ensuring that all components are functioning correctly to maintain optimal performance.

Conclusion

Electrostatic spray guns are an essential tool for achieving high-quality finishes in various industries. With leading manufacturers like Ramseier Koatings Technologies Holdings Ltd., Graco, Ransburg, Binks, and Wagner, businesses in Liechtenstein have access to top-notch equipment that enhances efficiency and reduces waste. By understanding the benefits and features of these spray guns, manufacturers can make informed decisions that lead to better coating results.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.