Content Menu

● Why Consistency Matters in Powder Coating

>> Impact on Product Quality

>> Color Uniformity and Standards

>> Cost Control and Waste Reduction

● Factors Influencing Consistency in Powder Coating

>> Powder Quality and Formulation

>> Equipment Settings and Environment

● How Automatic Spray Guns Enhance Consistency

>> Precise Control of Application Parameters

>> Repeatability and Uniform Coverage

>> Reduction of Overspray and Material Loss

● Additional Benefits of Automatic Spray Guns

>> Increased Production Speed and Efficiency

>> Enhanced Worker Safety and Comfort

>> Flexibility and Integration in Manufacturing Lines

● Key Considerations When Implementing Automatic Spray Guns

>> Initial Investment and Maintenance

>> Training and Process Setup

● Conclusion

● Frequently Asked Questions (FAQs)

Powder coating is a popular industrial finishing process prized for its durability, vibrant appearance, and environmental advantages. However, one of the most critical elements to ensure product quality and efficiency in powder coating is consistency. Achieving consistent application throughout a production run not only enhances the aesthetic and protective qualities of the coated items but also reduces waste, rework, and production costs. In modern powder coating operations, automatic spray guns play a vital role in delivering this consistency by controlling variables that can be challenging to manage manually.

Why Consistency Matters in Powder Coating

Impact on Product Quality

Consistency in powder coating directly affects the quality and appearance of the finished product. When powder coatings are applied uniformly, the resulting film is smooth, even, and free from defects such as uneven thickness, color variations, or texture irregularities. These factors contribute to not only the aesthetic appeal but also the protective performance, such as corrosion resistance and durability. Variations in coating thickness can lead to weak spots that are prone to wear or corrosion, diminishing the lifespan of the product.

Color Uniformity and Standards

Color consistency is a particularly challenging aspect that demands attention in powder coating operations. Coating colors often need to meet specific industry standards such as RAL or custom color matching requirements. Even small deviations in color or finish can be noticeable to end customers and hurt brand reputation. Color inconsistency may stem from variations in powder composition or from the application process itself, making it critical to have well-controlled spraying processes and uniform coating thickness.

Cost Control and Waste Reduction

When powder coating is inconsistent, it frequently leads to defects requiring rework, including sanding, repainting, or outright rejection of parts. These corrective actions incur additional labor costs, material waste, and production downtime. Inconsistent coatings also increase powder wastage due to overspray or excessive material use. By ensuring consistency, manufacturers optimize material usage, reduce operational costs, and enhance workflow efficiency across production lines.

Factors Influencing Consistency in Powder Coating

Powder Quality and Formulation

Powder formulation—including pigment selection, resin blends, and additives—plays a major role in coating performance and consistency. High-quality powders with uniform particle size and morphology improve the flow and adherence characteristics of the coating. Particle size distribution affects powder flowability and the smoothness of the final cured film. Proper formulation reduces coating defects such as orange peel, uneven gloss, or patchiness.

Equipment Settings and Environment

Consistent equipment parameters, including spray gun settings, air pressure, and electrostatic voltage, are essential in maintaining uniform application. Variability in these parameters can cause inconsistency in coating thickness and finish quality. Moreover, environmental factors such as temperature and humidity affect powder behavior and curing, necessitating controlled conditions for reliable results.

How Automatic Spray Guns Enhance Consistency

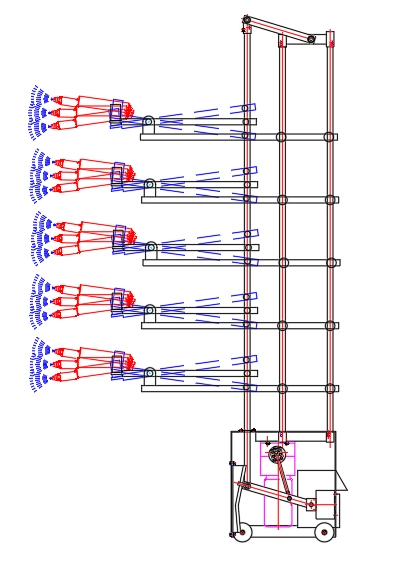

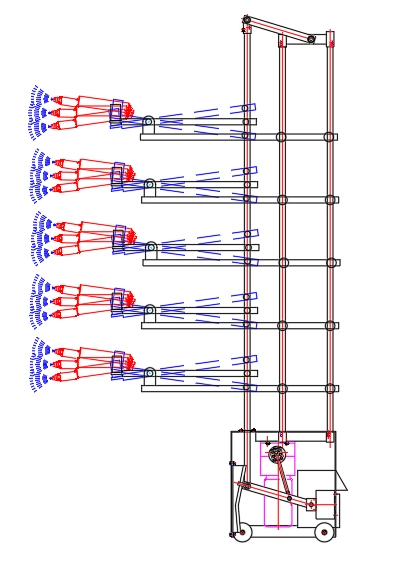

Precise Control of Application Parameters

Automatic spray guns utilize programmed controls to regulate powder flow rate, spray distance, gun movement, and spray pattern. This precision limits human variability and ensures each product receives the exact amount of powder needed. The ability to replicate these settings across long production runs is critical to batch-to-batch consistency.

Repeatability and Uniform Coverage

Since automatic guns operate robotically or with automated systems, they can repeat the same movements and spraying actions flawlessly. This repetition guarantees uniform coverage across complex shapes and large surface areas, resulting in consistent thickness and finish quality. Unlike manual spraying, there is no deviation due to operator fatigue or technique differences.

Reduction of Overspray and Material Loss

Advanced automatic systems optimize powder transfer efficiency by controlling spray parameters and paths. This minimizes overspray, thus reducing wasted material and improving powder utilization. Efficient powder application lowers overall production costs and supports sustainability efforts.

Additional Benefits of Automatic Spray Guns

Increased Production Speed and Efficiency

Automatic spray guns can coat surfaces much faster than manual methods, significantly increasing throughput without sacrificing quality. They enable continuous, uninterrupted operation that boosts production capacity and helps meet tighter delivery schedules.

Enhanced Worker Safety and Comfort

By automating the spraying process, operators are removed from direct exposure to potentially hazardous coatings. This reduces the risks associated with inhalation or skin contact with powders and solvents. Additionally, automation alleviates the physical demands on workers, reducing fatigue and injury risks related to repetitive manual spraying.

Flexibility and Integration in Manufacturing Lines

Modern automatic spray guns can be programmed for frequent changes in color, coating type, and spray patterns, making them ideal for variable production runs. They integrate well with automated handling and curing systems, contributing to streamlined, efficient manufacturing workflows.

Key Considerations When Implementing Automatic Spray Guns

Initial Investment and Maintenance

Automatic systems require significant initial capital investment for the spray guns, robotic integrations, and control systems. Additionally, routine maintenance and occasional part replacements are necessary to keep equipment operating reliably. While these costs may be high upfront, the long-term savings through reduced waste, labor, and rework often justify the expenditure.

Training and Process Setup

Successful implementation involves adequate operator training and detailed process setup. Calibration, testing, and fine-tuning of spray parameters are vital to achieve desired coating results. Once optimized, automated systems consistently reproduce these results across production runs.

Conclusion

Consistency is the cornerstone of successful powder coating operations. It ensures high-quality finishes, controls costs, and maintains customer satisfaction. Automatic spray guns are indispensable tools that address the challenges of maintaining this consistency, delivering precise, repeatable, and efficient powder application. Manufacturing facilities embracing automation in powder coating benefit from improved product quality, reduced material waste, and enhanced operational safety. As the powder coating industry advances, integrating automatic spray technology becomes essential for competitive, high-quality production.

Frequently Asked Questions (FAQs)

Q1: Why is consistency important in powder coating?

A1: Consistency ensures uniform thickness, color, and finish quality, which are crucial for durability, appearance, and reducing costly rework.

Q2: How do automatic spray guns improve powder coating quality?

A2: They provide precise control over spray parameters and repeatability, reducing human error and ensuring uniform coating on every piece.

Q3: Are there cost savings associated with automatic spray guns?

A3: Yes, automatic guns reduce powder waste, labor costs, and rework, which lowers overall production expenses despite higher initial investments.

Q4: What maintenance challenges come with automatic spray guns?

A4: They require regular inspection, cleaning, and replacement of components to maintain performance, which may increase maintenance costs.

Q5: Can automatic spray guns handle different powder types and production requirements?

A5: Yes, these systems are highly flexible and programmable, allowing for various powder coatings, colors, and complex spray patterns suitable for diverse production needs.

[1](https://www.tiger-coatings.com/us-en/tiger-group/tiger-blog/how-to-ensure-batch-to-batch-consistency-for-powder-coating)

[2](https://www.hinahpowdercoating.com/blog/manual-vs-automatic-powder-coating-gun.html)

[3](https://www.codinter.com/en/automatic-spray-guns-a-complete-guide/)

[4](https://powdervisioninc.com/2024/04/creating-custom-colors-the-science-behind-color-matching-in-powder-coating/)

[5](https://www.powdersprayline.com/what-are-the-advantages-and-disadvantages-of-the-automatic-reciprocator-spray-gun.html)

[6](https://www.duboisequipment.com/automated-spray-coating-machine-guide/)

[7](https://www.tiger-coatings.com/us-en/blog/why-particle-morphology-matters-in-powder-coating-a-deep-dive-into-performance-control-and-optimization)

[8](https://www.hinahcoatingline.com/news/automatic-powder-coating-machine-how-does-it-enhance-production-efficiency)

[9](https://finishingandcoating.com/index.php/powder-coat/1549-why-powder-coating-consistency-is-vitaly-important)

[10](https://reasonablechoice.net/en/blog/automation-of-powder-coating-application)

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.