Content Menu

● Understanding Electrostatic Spray Guns

>> What is an Electrostatic Spray Gun?

>> Benefits of Using Electrostatic Spray Guns

● Key Features to Consider

>> 1. Transfer Efficiency

>> 2. Ease of Use

>> 3. Durability

>> 4. Price and Warranty

● Top Manual Electrostatic Spray Guns for Small Businesses

>> 1. Graco Pro Xp Series

>> 2. Wagner FinishPro 130

>> 3. OTSON OTS-3000+G7

>> 4. Ransburg Vector Series

>> 5. Dezhou Aohai AH-S500

● Maximizing ROI with Electrostatic Spray Guns

>> Proper Setup and Maintenance

>> Training Employees

>> Monitoring Performance

● Conclusion

>> Frequently Asked Questions

In the world of small businesses, efficiency and cost-effectiveness are paramount. One area where these principles can be applied is in the choice of equipment, particularly when it comes to painting and coating applications. Manual electrostatic spray guns have gained popularity due to their ability to provide high-quality finishes while minimizing waste. This article explores the best manual electrostatic spray guns available, focusing on their return on investment (ROI) for small businesses.

Understanding Electrostatic Spray Guns

What is an Electrostatic Spray Gun?

An electrostatic spray gun uses electrostatic charge to attract paint particles to the surface being coated. This technology enhances the efficiency of the painting process by ensuring that more paint adheres to the surface rather than being lost to overspray. The result is a smoother finish and reduced material costs, making it an attractive option for small businesses.

Benefits of Using Electrostatic Spray Guns

1. High Transfer Efficiency: Electrostatic guns can achieve transfer efficiencies of up to 90%, meaning less paint is wasted.

2. Reduced Overspray: The electrostatic charge helps to minimize overspray, which is particularly beneficial in environments where cleanliness is crucial.

3. Versatility: These guns can be used with a variety of coatings, including water-based and solvent-based paints.

4. Cost Savings: By reducing paint waste and improving application efficiency, businesses can save significantly on material costs.

Key Features to Consider

When selecting a manual electrostatic spray gun, small businesses should consider several key features to ensure they are making a wise investment.

1. Transfer Efficiency

The primary advantage of electrostatic spray guns is their high transfer efficiency. Look for models that offer at least 80% efficiency to maximize your ROI.

2. Ease of Use

A user-friendly design can significantly reduce training time and operational downtime. Features such as adjustable spray patterns and easy maintenance are essential.

3. Durability

Investing in a durable spray gun can save money in the long run. Look for models made from high-quality materials that can withstand frequent use.

4. Price and Warranty

Consider the initial cost of the spray gun and the warranty offered. A longer warranty can provide peace of mind and protect your investment.

Top Manual Electrostatic Spray Guns for Small Businesses

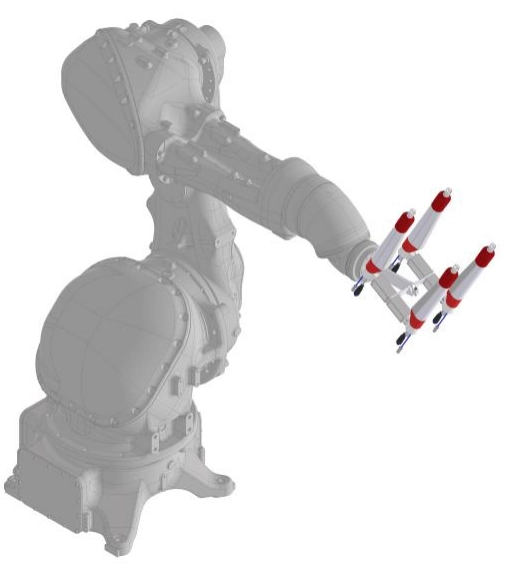

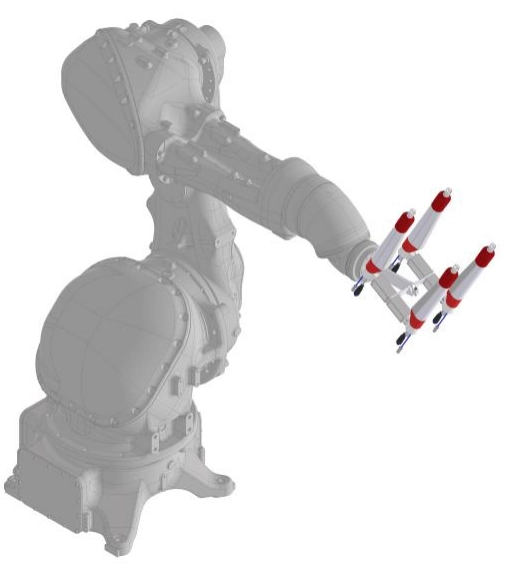

1. Graco Pro Xp Series

The Graco Pro Xp series is renowned for its high transfer efficiency and durability. These guns are designed for both air spray and air-assisted applications, making them versatile for various projects. The Pro Xp series also features a robust construction that can withstand the rigors of daily use.

2. Wagner FinishPro 130

The Wagner FinishPro 130 is an excellent choice for small businesses looking for a balance between performance and affordability. This HVLP (High Volume Low Pressure) gun offers adjustable flow control and is compatible with a wide range of coatings. Its compact design makes it ideal for smaller workshops.

3. OTSON OTS-3000+G7

The OTSON OTS-3000+G7 is a lightweight manual electrostatic spray gun that excels in applying both solvent and waterborne paints. Its high atomization quality ensures a smooth finish, while its low VOC emissions make it suitable for environmentally conscious businesses.

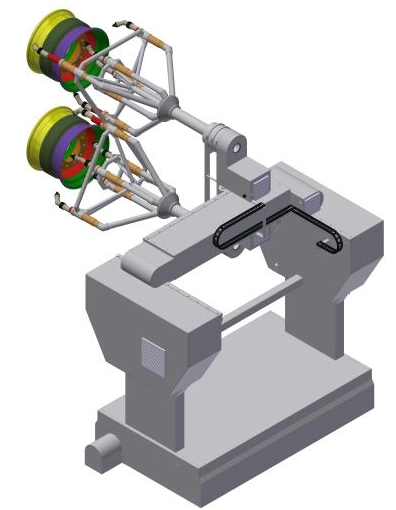

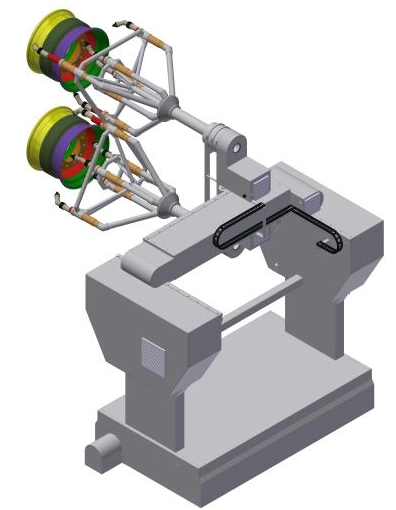

4. Ransburg Vector Series

The Ransburg Vector series is known for its ergonomic design and high transfer efficiency. These guns are particularly effective for solvent-based coatings and offer customizable configurations to meet specific application needs.

5. Dezhou Aohai AH-S500

The Dezhou Aohai AH-S500 is a high-pressure manual electrostatic spray gun that delivers excellent performance for water-based and powder coatings. Its ergonomic design reduces operator fatigue, making it a great choice for long painting sessions.

Maximizing ROI with Electrostatic Spray Guns

Proper Setup and Maintenance

To ensure that your electrostatic spray gun operates at peak efficiency, proper setup and maintenance are crucial. Follow the manufacturer's guidelines for setup, and regularly clean the gun to prevent clogs and ensure consistent performance.

Training Employees

Investing in training for your employees can significantly enhance the effectiveness of your spray gun. Proper training ensures that your team understands how to use the equipment efficiently, which can lead to better finishes and reduced waste.

Monitoring Performance

Keep track of your material usage and the quality of your finishes. Monitoring these metrics can help you identify areas for improvement and ensure that you are getting the best ROI from your equipment.

Conclusion

Choosing the right manual electrostatic spray gun can significantly impact the efficiency and cost-effectiveness of your small business. By considering factors such as transfer efficiency, ease of use, durability, and price, you can select a model that offers the best return on investment. The Graco Pro Xp series, Wagner FinishPro 130, OTSON OTS-3000+G7, Ransburg Vector series, and Dezhou Aohai AH-S500 are all excellent options that can help your business thrive.

Frequently Asked Questions

1. What is the average cost of a manual electrostatic spray gun?

- Prices can range from $300 to $3,500 depending on the brand and features.

2. How do I maintain my electrostatic spray gun?

- Regular cleaning, proper storage, and following the manufacturer's maintenance guidelines are essential.

3. Can I use any type of paint with an electrostatic spray gun?

- Most electrostatic spray guns are compatible with a variety of coatings, but always check the manufacturer's specifications.

4. What is the benefit of using HVLP technology?

- HVLP technology reduces overspray and improves transfer efficiency, making it ideal for detailed work.

5. How can I improve the efficiency of my spray gun?

- Proper setup, regular maintenance, and employee training can all enhance the efficiency of your electrostatic spray gun.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.