Content Menu

● Understanding Manual Electrostatic Spray Guns

>> What Are Manual Electrostatic Spray Guns?

>> How Do They Work?

● Industries That Benefit from Manual Electrostatic Spray Guns

>> 1. Automotive Industry

>>> Applications in Automotive

>>> Benefits

>> 2. Furniture and Wood Finishing

>>> Applications in Furniture

>>> Benefits

>> 3. Industrial Manufacturing

>>> Applications in Industrial Manufacturing

>>> Benefits

>> 4. Aerospace Industry

>>> Applications in Aerospace

>>> Benefits

>> 5. Construction and Heavy Equipment

>>> Applications in Construction

>>> Benefits

● Advantages of Manual Electrostatic Spray Guns

>> High Transfer Efficiency

>> Reduced VOC Emissions

>> Improved Finish Quality

>> Versatility

>> Cost-Effectiveness

● Conclusion

>> Frequently Asked Questions

Manual electrostatic spray guns have become essential tools in various industries due to their efficiency and effectiveness in applying coatings. These guns utilize electrostatic technology to enhance the transfer of paint to surfaces, resulting in less waste and a superior finish. This article explores the industries that benefit most from manual electrostatic spray guns, detailing their applications, advantages, and the technology behind them.

Understanding Manual Electrostatic Spray Guns

What Are Manual Electrostatic Spray Guns?

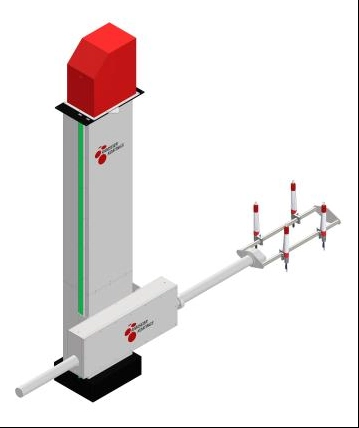

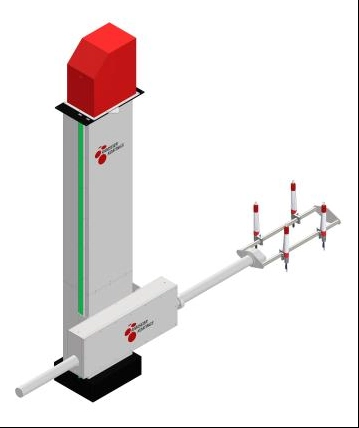

Manual electrostatic spray guns are devices that apply an electric charge to paint particles as they are sprayed onto a surface. This charge causes the paint to be attracted to the grounded object, ensuring a more uniform application and reducing overspray. The technology behind these guns allows for high transfer efficiency, which is crucial in industries where material costs and environmental impact are significant concerns.

How Do They Work?

The operation of a manual electrostatic spray gun involves several key components:

- Electrostatic Charge: The gun generates a high voltage that charges the paint particles.

- Grounding: The object being painted is grounded, creating a path for the charged particles to adhere to the surface.

- Spray Pattern Control: Operators can adjust the spray pattern and flow rate, allowing for precision in application.

This combination of features makes manual electrostatic spray guns particularly effective for various applications.

Industries That Benefit from Manual Electrostatic Spray Guns

1. Automotive Industry

The automotive industry is one of the largest users of manual electrostatic spray guns. These guns are employed in both manufacturing and refinishing processes.

Applications in Automotive

- Vehicle Painting: Manual electrostatic spray guns provide a high-quality finish with minimal overspray, which is crucial for automotive aesthetics.

- Touch-Up Work: They are also used for touch-ups and repairs, allowing for precise application in hard-to-reach areas.

Benefits

The high transfer efficiency of electrostatic guns reduces paint waste, which is particularly important given the high costs associated with automotive paints. Additionally, the ability to achieve a smooth finish enhances the overall quality of the vehicle.

2. Furniture and Wood Finishing

The furniture industry relies heavily on manual electrostatic spray guns for finishing wood products.

Applications in Furniture

- Coating Wood Surfaces: These guns are used to apply stains, lacquers, and paints to wooden furniture, ensuring an even coat that enhances the wood's natural beauty.

- Complex Shapes: The electrostatic charge helps in coating intricate designs and shapes, which are common in furniture manufacturing.

Benefits

Using manual electrostatic spray guns in furniture finishing leads to reduced overspray and improved material utilization, which can significantly lower production costs.

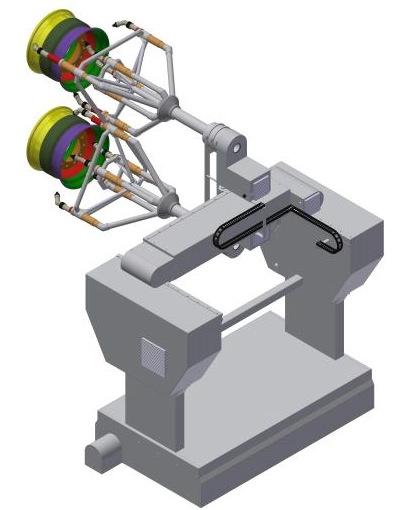

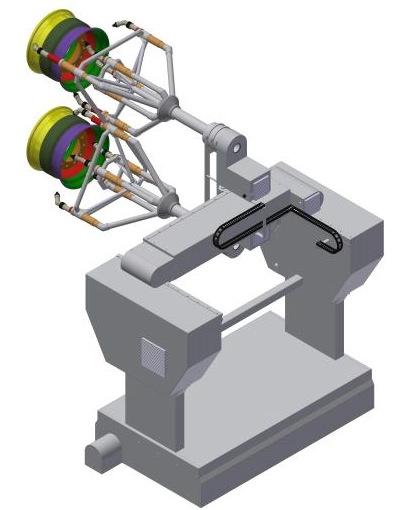

3. Industrial Manufacturing

In industrial manufacturing, manual electrostatic spray guns are used for coating various components and machinery.

Applications in Industrial Manufacturing

- Metal Parts Coating: These guns are ideal for applying protective coatings to metal parts, which helps in preventing corrosion and wear.

- Machinery Protection: They are also used to coat machinery components, ensuring durability and longevity.

Benefits

The ability to achieve a high-quality finish with less material makes manual electrostatic spray guns a preferred choice in industrial settings. This efficiency translates to lower operational costs and reduced environmental impact.

4. Aerospace Industry

The aerospace industry utilizes manual electrostatic spray guns for both manufacturing and maintenance of aircraft.

Applications in Aerospace

- Aircraft Coating: These guns are used to apply specialized coatings that protect aircraft from environmental damage.

- Component Finishing: They are also employed in finishing various aircraft components, ensuring compliance with strict safety and quality standards.

Benefits

The precision and efficiency of manual electrostatic spray guns are critical in aerospace applications, where even minor imperfections can lead to significant safety issues.

5. Construction and Heavy Equipment

In the construction sector, manual electrostatic spray guns are used for coating heavy machinery and equipment.

Applications in Construction

- Machinery Coating: These guns are used to apply protective coatings to construction equipment, which helps in extending the lifespan of the machinery.

- Surface Finishing: They are also employed in finishing surfaces of buildings and structures, providing both aesthetic and protective benefits.

Benefits

The use of manual electrostatic spray guns in construction leads to improved efficiency in coating applications, reducing the time and materials needed for surface finishing.

Advantages of Manual Electrostatic Spray Guns

High Transfer Efficiency

One of the most significant advantages of manual electrostatic spray guns is their high transfer efficiency, often exceeding 90%. This means that more paint adheres to the surface rather than being lost to overspray, resulting in cost savings and reduced environmental impact.

Reduced VOC Emissions

Electrostatic spray guns contribute to lower volatile organic compound (VOC) emissions compared to traditional spray methods. This is particularly important in industries where environmental regulations are stringent.

Improved Finish Quality

The electrostatic charge helps in achieving a smoother and more uniform finish, which is essential in industries where aesthetics are critical, such as automotive and furniture manufacturing.

Versatility

Manual electrostatic spray guns can be used with a variety of coatings, including water-based and solvent-based paints. This versatility makes them suitable for a wide range of applications across different industries.

Cost-Effectiveness

By reducing paint waste and improving application efficiency, manual electrostatic spray guns can lead to significant cost savings over time. This makes them an attractive option for businesses looking to optimize their production processes.

Conclusion

Manual electrostatic spray guns are invaluable tools across various industries, including automotive, furniture, industrial manufacturing, aerospace, and construction. Their ability to provide high transfer efficiency, reduce waste, and improve finish quality makes them a preferred choice for many applications. As industries continue to seek ways to enhance efficiency and reduce environmental impact, the use of manual electrostatic spray guns is likely to grow.

Frequently Asked Questions

1. What is the main advantage of using manual electrostatic spray guns?

- The main advantage is their high transfer efficiency, which reduces paint waste and improves application quality.

2. In which industries are manual electrostatic spray guns most commonly used?

- They are commonly used in the automotive, furniture, industrial manufacturing, aerospace, and construction industries.

3. How do manual electrostatic spray guns reduce VOC emissions?

- They minimize overspray and ensure more paint adheres to the surface, leading to lower volatile organic compound emissions.

4. Can manual electrostatic spray guns be used with different types of coatings?

- Yes, they can be used with both water-based and solvent-based coatings, making them versatile for various applications.

5. What maintenance is required for manual electrostatic spray guns?

- Regular cleaning and inspection of the gun components are necessary to ensure optimal performance and longevity.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.