Content Menu

● Understanding Electrostatic Spray Guns

>> How Electrostatic Spray Guns Work

>> Benefits of Electrostatic Spraying in Metal Finishing

● Types of Electrostatic Spray Guns for Metal Finishing

>> 1. Corona Electrostatic Spray Guns

>> 2. Tribo Electrostatic Spray Guns

>> 3. Hybrid Electrostatic Spray Guns

>> 4. Electrostatic Air-Assisted Spray Guns (Liquid Coatings)

● Key Features to Consider for the Best Performance

>> Transfer Efficiency and Coating Uniformity

>> Material Compatibility

>> Ease of Use and Maintenance

>> Safety and Compliance

● Leading Electrostatic Spray Guns for Metal Finishing

>> Wagner Evo Electrostatic Spray Guns

>> Nordson Gemini Tribo Guns

>> Ransburg Electrostatic Air-Assisted Guns

>> Graco Electrostatic Systems

● Tips for Achieving the Best Metal Finishing Results with Electrostatic Guns

>> Proper Grounding

>> Correct Charging Method

>> Optimum Gun Settings

>> Regular Maintenance

>> Environmental Conditions

● Common Challenges and How to Overcome Them

>> Uneven Coating on Complex Shapes

>> Arcing and Sparks

>> Overspray and Material Waste

>> Equipment Downtime

● Frequently Asked Questions About Electrostatic Spray Guns for Metal Finishing

● Conclusion

Electrostatic spray guns have revolutionized the metal finishing industry by providing superior coating quality, enhanced transfer efficiency, and environmental benefits. Choosing the best electrostatic spray gun for metal finishing, however, depends on multiple factors including the type of metal surface, coating materials, production scale, and desired finish quality. This article explores the key features of different types of electrostatic spray guns, tips for effective metal finishing, and comparisons to help manufacturers and professionals select the optimal equipment for their needs.

Understanding Electrostatic Spray Guns

Electrostatic spray guns use electrically charged particles to attract paint or coating materials to metal surfaces, improving coverage and minimizing overspray. The technology enables powders or liquids to be atomized and sprayed onto grounded metal substrates, where the charged particles cling evenly.

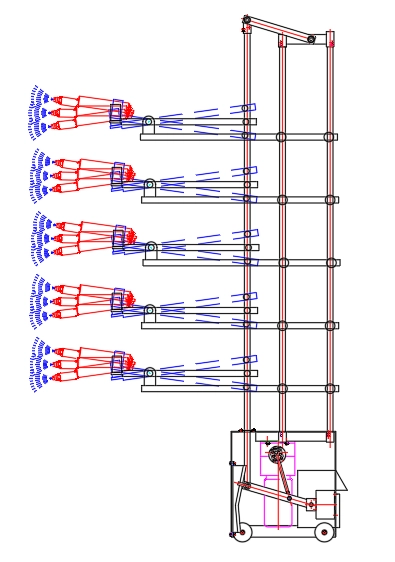

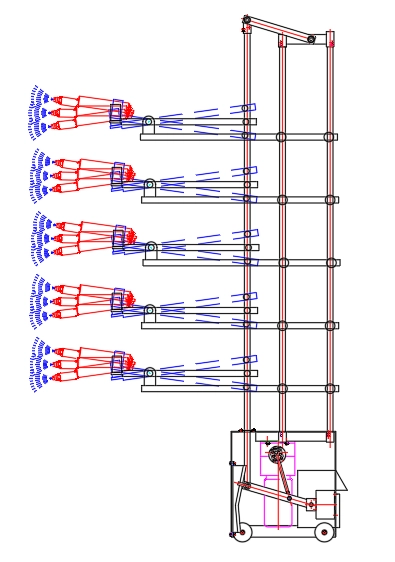

How Electrostatic Spray Guns Work

Electrostatic spray guns generate an electrostatic field through a charging device, usually a high-voltage power supply connected to the spray gun. The particles leaving the nozzle carry a charge opposite to that on the grounded metal surface. This charge difference creates an attraction force, effectively pulling the coating material onto the metal.

Benefits of Electrostatic Spraying in Metal Finishing

- Improved Adhesion: Electrostatic attraction ensures uniform coating adherence on complex metal geometries.

- Higher Transfer Efficiency: More coating material lands on the metal surface, reducing waste.

- Reduced Overspray and VOCs: Less airborne paint particles means improved workplace safety and environmental compliance.

- Faster Application: Enhanced transfer rates shorten production cycles.

Types of Electrostatic Spray Guns for Metal Finishing

Selecting the right electrostatic spray gun depends on whether liquid paints, powder coatings, or specialty finishes are used. The following are the main types utilized in metal finishing.

1. Corona Electrostatic Spray Guns

Corona spray guns operate by generating a corona discharge around the nozzle tip to charge the paint particles.

- Ideal for powder coating applications.

- Provide a strong electrostatic charge enabling excellent wrap-around effects.

- Suitable for a wide range of metal shapes but can be sensitive to humidity.

2. Tribo Electrostatic Spray Guns

Tribo guns charge particles through friction as they pass along a charged tube or barrel.

- Commonly used for powder coatings.

- Generate a stable and consistent charge with less sensitivity to humidity.

- Enable coating delicate or heat-sensitive metals without risk of corona discharge damage.

3. Hybrid Electrostatic Spray Guns

Hybrid guns combine corona and tribo charging technologies to exploit the advantages of both.

- Provide flexibility to handle multiple materials and production requirements.

- Allow operators to switch charging methods depending on coating type or surface.

- Increasingly popular in versatile metal finishing operations.

4. Electrostatic Air-Assisted Spray Guns (Liquid Coatings)

These guns charge liquid paints or primers electrically while atomizing the material with compressed air.

- Commonly applied in automotive and appliance metal finishing.

- Offer fine atomization with electrostatic adhesion, improving finish smoothness.

- Some advanced models feature adjustable voltage and flow settings for precise control.

Key Features to Consider for the Best Performance

When selecting an electrostatic spray gun for metal finishing, several criteria should guide the buyer's decision.

Transfer Efficiency and Coating Uniformity

High transfer efficiency guarantees more paint adheres to the metal surface rather than wasted as overspray. Guns that deliver stable, consistent electrostatic charges typically produce superior uniformity, reducing defects like orange peel or uneven thickness.

Material Compatibility

The coating materials—whether powders, solvents, or water-based—affect the choice. Some guns are optimized for powder coatings and won't perform well with liquid paints and vice versa. Confirm that the gun supports the desired coating viscosity and particle type.

Ease of Use and Maintenance

Powerful electrostatic spray guns can be complex. Look for user-friendly controls for voltage, air pressure, and flow adjustment, as well as guns that are easy to clean and maintain to minimize downtime in busy production environments.

Safety and Compliance

Electrostatic guns require high voltages and generate charged particles. Safety features like automatic shutoff, overflow protection, and grounding mechanisms are essential. Additionally, the technology should comply with environmental regulations around VOC emissions and operator health.

Leading Electrostatic Spray Guns for Metal Finishing

Several brands dominate the market with innovative electrostatic spray guns tailored for metal finishing needs. Here are examples of notable models:

Wagner Evo Electrostatic Spray Guns

Wagner's Evo line integrates adjustable corona and tribo charging, suitable for diverse powder coatings on metals. These guns offer excellent transfer efficiency over 90% and strong wrap-around effects, ensuring thorough coverage without excess material use.

Nordson Gemini Tribo Guns

Nordson's Gemini tribo guns are prized for consistent charge generation and durability. Ideal for metal finishing sensitive to humidity, they handle delicate finishes with high precision and minimal overspray, reducing defects and rework.

Ransburg Electrostatic Air-Assisted Guns

Ransburg provides advanced electrostatic air-assisted liquid spray guns widely used in automotive metal finishing. Featuring customizable voltage and flow rates, they produce exceptionally smooth and durable finishes on metal parts.

Graco Electrostatic Systems

Graco manufactures a broad array of electrostatic spray equipment known for reliability and ease of maintenance. Their powder and liquid electrostatic guns perform consistently across high-volume metal coating lines.

Tips for Achieving the Best Metal Finishing Results with Electrostatic Guns

Optimizing electrostatic spraying parameters and following best practices directly impacts the coating quality.

Proper Grounding

Ensuring the metal objects are properly grounded is crucial for electrostatic attraction. Poor grounding reduces charge differences and leads to inconsistent coating coverage.

Correct Charging Method

Match the charging method (corona or tribo) to the coating and environment. Corona works well in dry conditions for powders, while tribo is better in high humidity or for heat-sensitive metals.

Optimum Gun Settings

Adjust voltage, air pressure, and fluid flow appropriately for the specific coating. Overcharging can cause arcing and defects, while undercharging reduces transfer efficiency.

Regular Maintenance

Clean guns after each use to prevent buildup, especially with powder coatings that may clog nozzles. Maintain power supply units according to manufacturer instructions.

Environmental Conditions

Control humidity and temperature in the spray booth. Optimal conditions enhance adhesion and coating flow.

Common Challenges and How to Overcome Them

Electrostatic spray technology poses challenges that can impact metal finishing outcomes if not addressed.

Uneven Coating on Complex Shapes

Use guns with proven wrap-around capabilities, such as tribo or hybrid models, and optimize object orientation in the spray booth. Multiple passes may be necessary.

Arcing and Sparks

Prevent by ensuring the metal is grounded and the spray booth is free from conductive powders or moisture buildup.

Overspray and Material Waste

Fine-tune voltage and flow rates and use electrostatic guns with high transfer efficiency specs to limit waste.

Equipment Downtime

Invest in guns with robust construction and easy-to-maintain designs, and schedule routine checks of the electrical charging systems.

Frequently Asked Questions About Electrostatic Spray Guns for Metal Finishing

Q1: What type of electrostatic spray gun is best for powder coatings on metal?

Typically, tribo and corona guns are preferred for powder coatings. Tribo guns perform better in humid environments, while corona guns provide a stronger charge ideal for dry conditions.

Q2: Can electrostatic spray guns be used with all metal types?

Yes, but proper grounding is critical. The metal must be conductive for the electrostatic effect to work efficiently.

Q3: How does electrostatic spraying improve metal finish durability?

The uniform coating thickness and strong adhesion reduce defects and enhance protection against corrosion and wear.

Q4: What maintenance is required for electrostatic spray guns?

Regular cleaning to remove powder or paint residues, inspection of charging components, and verification of grounding systems are essential.

Q5: Are electrostatic spray guns environmentally friendly?

Yes, they reduce overspray and VOC emissions by improving transfer efficiency, aligning with stricter environmental standards.

Conclusion

The best electrostatic spray gun for metal finishing depends on the specific application and environmental conditions. Corona, tribo, and hybrid guns each offer unique advantages for powders, liquids, and complex shapes. Leading manufacturers provide versatile, high-efficiency guns that can transform metal finishing by improving coating quality, reducing waste, and speeding production. Understanding key features such as transfer efficiency, charging method, and gun maintenance will help users select and optimize the right electrostatic spray gun for durable, high-quality metal finishes.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.