Content Menu

● Understanding Electrostatic Spray Technology

>> The Science Behind Electrostatics

>> The "Wrap-Around" Effect

● Components of a Manual Electrostatic Spray Gun

>> The Gun Body and Handle

>> High-Voltage Generator

>> Fluid Nozzle and Air Cap

>> Electrode

>> Paint Delivery System

>> Grounding Cable

● How a Manual Electrostatic Spray Gun Works

>> Step-by-Step Operation

● Advantages of Using Manual Electrostatic Spray Guns

>> Enhanced Transfer Efficiency

>> Superior Finish Quality

>> Reduced Material Consumption

>> Environmental Benefits

>> Increased Productivity

>> Versatility

● Applications of Manual Electrostatic Spray Guns

>> Automotive Industry

>> Aerospace Manufacturing

>> Furniture Manufacturing

>> General Metal Finishing

>> Agricultural Equipment

● Choosing the Right Electrostatic Spray Gun

>> Coating Material Type

>> Power Source

>> Ergonomics and Weight

>> Safety Features

>> Maintenance and Durability

● Best Practices for Operating Manual Electrostatic Spray Guns

>> Proper Grounding of Workpiece

>> Maintaining Optimal Distance

>> Consistent Gun Movement

>> Proper Atomization Settings

>> Regular Cleaning and Maintenance

>> Personal Protective Equipment (PPE)

>> Safety Considerations

● Maintenance and Troubleshooting

>> Routine Cleaning

>> Inspection and Replacement

>> Common Troubleshooting Scenarios

● The Future of Electrostatic Spraying

>> Smart Technology Integration

>> Enhanced Material Compatibility

>> Improved Ergonomics and Lightweight Design

>> Automated and Robotic Integration

● Conclusion

● Frequently Asked Questions

>> Q1: What is the main difference between a conventional spray gun and a manual electrostatic spray gun?

>> Q2: Can manual electrostatic spray guns be used with any type of paint?

>> Q3: Why is proper grounding important for electrostatic spray guns?

>> Q4: How does the "wrap-around" effect benefit the painting process?

>> Q5: What safety precautions should be taken when using a manual electrostatic spray gun?

>> Q6: How often should a manual electrostatic spray gun be cleaned?

>> Q7: Can electrostatic spray guns save money?

Manual electrostatic spray guns represent a significant advancement in coating technology, offering enhanced efficiency and quality compared to conventional spray methods. For industries ranging from automotive and aerospace to furniture and general manufacturing, achieving a uniform, durable, and aesthetically pleasing finish is paramount. Xinshunheng Industrial Co., Ltd., a leading provider of innovative industrial solutions, recognizes the critical role these tools play in modern production processes. This article will explore the intricate workings of manual electrostatic spray guns, their advantages, proper usage, and maintenance, ensuring users can maximize their potential.

Understanding Electrostatic Spray Technology

Electrostatic spray technology leverages the principles of electrostatics to apply coatings more efficiently and uniformly. Unlike traditional spraying, which relies solely on air pressure to atomize and direct paint particles, electrostatic systems introduce an electrical charge. This fundamental difference drastically improves transfer efficiency and finish quality.

The Science Behind Electrostatics

At the heart of electrostatic spraying is the concept of opposite charges attracting. A high-voltage electrostatic field is created between the spray gun nozzle and the grounded object being painted. As the coating material exits the gun, it passes through this field and acquires a negative charge. The object to be coated, typically made of conductive material, is grounded, thus possessing a positive or neutral charge. This difference in charge causes the negatively charged paint particles to be strongly attracted to the grounded workpiece.

The "Wrap-Around" Effect

One of the most significant benefits of this electrostatic attraction is the "wrap-around" effect. Charged paint particles, instead of simply traveling in a straight line, are drawn to all accessible surfaces of the workpiece, even those not directly in the spray path. This phenomenon allows for more even coverage on complex shapes and reduces overspray, leading to material savings and a cleaner work environment.

Components of a Manual Electrostatic Spray Gun

A manual electrostatic spray gun is a sophisticated piece of equipment comprising several key components that work in concert to achieve optimal coating results. Xinshunheng Industrial Co., Ltd. emphasizes the importance of understanding each part for effective operation and maintenance.

The Gun Body and Handle

The main structure of the spray gun, ergonomically designed for comfortable manual operation. It houses the internal components and provides a grip for the operator. The design often includes controls for fluid flow and air pressure.

High-Voltage Generator

This internal or external component is responsible for generating the high voltage (typically tens of kilovolts) required to charge the paint particles. Safety features are integral to prevent electrical hazards.

Fluid Nozzle and Air Cap

These components atomize the paint. The fluid nozzle controls the flow of liquid paint, while the air cap, fed by compressed air, breaks the liquid into fine droplets and shapes the spray pattern. In electrostatic guns, the nozzle is where the charge is typically applied to the atomized paint.

Electrode

Positioned near the fluid nozzle, the electrode imparts the electrostatic charge to the atomized paint particles as they exit the gun. The material and design of the electrode are crucial for consistent charging.

Paint Delivery System

This can be a gravity feed cup, a suction feed cup, or a pressure feed system connected to a remote paint pot or pump. The delivery system ensures a continuous supply of coating material to the gun.

Grounding Cable

Essential for safety and function, the grounding cable connects the workpiece to the earth, creating the necessary potential difference for electrostatic attraction. Without proper grounding, the electrostatic effect is nullified.

How a Manual Electrostatic Spray Gun Works

The operation of a manual electrostatic spray gun involves a precise sequence of steps, combining fluid dynamics with electrostatics to achieve a superior finish.

Step-by-Step Operation

1. Material Loading: The coating material, such as paint, powder, or liquid adhesive, is loaded into the gun's reservoir or connected to a central supply system.

2. Air and Fluid Activation: Compressed air is supplied to the gun, and the trigger is pulled to open the fluid needle, allowing the coating material to flow to the nozzle.

3. Atomization: As the coating material exits the nozzle, it is met by compressed air from the air cap, which atomizes it into a fine mist of droplets.

4. Electrostatic Charging: Simultaneously, the high-voltage generator is activated, and the electrode at the gun's tip imparts a negative electrical charge to the atomized particles.

5. Attraction to Grounded Workpiece: The negatively charged paint particles are then electrostatically attracted to the grounded workpiece. The difference in electrical potential ensures that the particles are drawn to the surface with high efficiency.

6. "Wrap-Around" Effect: Due to the electrostatic field, paint particles not only deposit on the directly sprayed surface but also wrap around edges and complex geometries, providing comprehensive coverage.

7. Even Deposition: The charged particles repel each other slightly as they approach the surface, leading to a more even and uniform film build, reducing sags and runs.

Advantages of Using Manual Electrostatic Spray Guns

Xinshunheng Industrial Co., Ltd. consistently recommends manual electrostatic spray guns due to their numerous benefits across various industrial applications.

Enhanced Transfer Efficiency

Electrostatic guns boast significantly higher transfer efficiency compared to conventional spray guns. This means a larger percentage of the coating material ends up on the workpiece, rather than becoming overspray. This efficiency translates directly into material savings, reducing costs and waste.

Superior Finish Quality

The electrostatic attraction ensures a more uniform and consistent coating thickness, even on intricate parts. This results in a smoother, more aesthetically pleasing finish with fewer defects like runs, sags, and orange peel. The "wrap-around" effect also contributes to better edge coverage.

Reduced Material Consumption

Due to higher transfer efficiency, less paint or coating material is required to achieve the desired film thickness. This not only saves on material costs but also reduces the frequency of paint changes and refills, improving productivity.

Environmental Benefits

With reduced overspray, less volatile organic compounds (VOCs) are released into the atmosphere. This makes electrostatic spraying a more environmentally friendly option, contributing to compliance with environmental regulations and promoting a healthier work environment.

Increased Productivity

Less time is spent on masking, cleaning up overspray, and redoing poorly coated parts. The faster and more efficient application process, coupled with reduced material handling, leads to increased throughput and overall productivity.

Versatility

Manual electrostatic spray guns can be used with a wide range of coating materials, including solvent-based, waterborne, and some powder coatings, making them versatile tools for diverse industrial needs.

Applications of Manual Electrostatic Spray Guns

The versatility and efficiency of manual electrostatic spray guns make them indispensable across a multitude of industries.

Automotive Industry

For painting vehicle bodies, components, and aftermarket parts, electrostatic guns ensure a high-quality, durable finish that is crucial for aesthetics and corrosion protection.

Aerospace Manufacturing

In the aerospace sector, precision and uniformity are critical. Electrostatic spraying is used for applying protective coatings, primers, and topcoats to aircraft components, where material efficiency and consistency are paramount.

Furniture Manufacturing

From metal frames to wooden components, electrostatic guns provide a smooth and even finish, enhancing the appearance and longevity of furniture pieces.

General Metal Finishing

Any industry that requires coating metal parts, such as appliances, electrical enclosures, or structural components, benefits from the efficiency and quality offered by electrostatic spraying.

Agricultural Equipment

Protective coatings on agricultural machinery benefit from the durable and uniform application provided by electrostatic spray guns, extending the life of equipment exposed to harsh environments.

Choosing the Right Electrostatic Spray Gun

Selecting the appropriate manual electrostatic spray gun from Xinshunheng Industrial Co., Ltd. requires considering several factors to match the tool to the specific application and coating material.

Coating Material Type

Different guns are optimized for specific types of coatings. Waterborne paints, for instance, require specialized guns with insulated components due to their conductivity. Solvent-based paints are generally less conductive and have broader compatibility. Powder coating guns are distinctly different from liquid spray guns.

Power Source

Manual electrostatic guns typically use either internal generators powered by batteries or external high-voltage power supplies connected via cables. The choice depends on mobility requirements and power availability.

Ergonomics and Weight

For manual operation, the gun's weight, balance, and ergonomic design are crucial for operator comfort and to reduce fatigue, especially during extended use.

Safety Features

Ensure the gun has adequate safety interlocks, grounding mechanisms, and voltage regulation to prevent accidental shocks or fires.

Maintenance and Durability

Consider the ease of cleaning, availability of spare parts, and the overall build quality to ensure a long service life and minimal downtime. Xinshunheng Industrial Co., Ltd. products are known for their durability and ease of maintenance.

Best Practices for Operating Manual Electrostatic Spray Guns

To achieve the best results and ensure safety, Xinshunheng Industrial Co., Ltd. advises adherence to best practices when operating manual electrostatic spray guns.

Proper Grounding of Workpiece

This is perhaps the most critical step. The workpiece must be properly grounded to allow the electrostatic attraction to occur. Without adequate grounding, the paint will not be attracted effectively, and the "wrap-around" effect will be minimal.

Maintaining Optimal Distance

The distance between the gun and the workpiece significantly impacts transfer efficiency and finish quality. Too close can lead to heavy film build and potential sags, while too far reduces the electrostatic effect and increases overspray. The optimal distance varies with the gun and material but typically ranges from 6 to 12 inches.

Consistent Gun Movement

Maintain a steady and consistent gun speed and pattern. Overlapping passes by about 50% ensures even coverage. Jerky movements can lead to uneven film thickness and defects.

Proper Atomization Settings

Adjust air pressure and fluid flow to achieve optimal atomization. The goal is to create a fine, uniform mist without excessive air turbulence, which can disrupt the electrostatic field.

Regular Cleaning and Maintenance

Clean the gun thoroughly after each use, especially the fluid passages, nozzle, and air cap. Regular maintenance, including checking for worn parts and ensuring proper insulation, is vital for performance and safety.

Personal Protective Equipment (PPE)

Operators should always wear appropriate PPE, including respirators, gloves, and protective clothing, to guard against inhalation of paint fumes and skin contact.

Safety Considerations

Be aware of the high voltage involved. Never touch the electrode or the workpiece during operation. Ensure the work area is well-ventilated and free from flammable vapors.

Maintenance and Troubleshooting

Regular maintenance is key to extending the life and maintaining the performance of your manual electrostatic spray gun. Xinshunheng Industrial Co., Ltd. provides guidelines to keep your equipment in top condition.

Routine Cleaning

* After Each Use: Flush the fluid passages with an appropriate cleaning solvent. Clean the exterior of the gun, especially the nozzle and air cap, to prevent paint buildup.

* Weekly/Monthly: Disassemble the air cap and fluid nozzle for a more thorough cleaning. Inspect O-rings and seals for wear and replace if necessary.

Inspection and Replacement

* Electrode: Regularly inspect the electrode for wear, damage, or paint buildup. A damaged or dirty electrode can impair charging efficiency.

* Cables and Hoses: Check all air, fluid, and high-voltage cables for kinks, cuts, or damage. Replace any compromised components immediately.

* Fluid Needle and Seat: Wear in these components can lead to leaks or inconsistent fluid flow. Replace them as part of routine maintenance.

Common Troubleshooting Scenarios

* Poor Atomization: Check air pressure, fluid viscosity, and ensure the nozzle and air cap are clean and undamaged.

* Inconsistent Spray Pattern: This could be due to a partially clogged nozzle, damaged air cap, or improper air pressure balance.

* Reduced Electrostatic Effect: Verify the workpiece is properly grounded. Check the high-voltage generator and the electrode for damage or contamination. Ensure there is no significant paint buildup on the gun tip that could short out the charge.

* Paint Runs/Sags: This often indicates excessive material application, improper gun distance, or incorrect fluid viscosity. Adjust settings accordingly.

The Future of Electrostatic Spraying

As industries continue to seek more efficient, sustainable, and high-quality finishing solutions, the technology behind manual electrostatic spray guns is also evolving. Xinshunheng Industrial Co., Ltd. anticipates advancements in several key areas.

Smart Technology Integration

Future electrostatic spray guns may incorporate smart sensors and IoT capabilities for real-time monitoring of spray parameters, film thickness, and environmental conditions. This data can be used for predictive maintenance, process optimization, and quality control.

Enhanced Material Compatibility

Research is ongoing to expand the range of coating materials that can be effectively applied using electrostatic methods, including more advanced functional coatings and a wider array of waterborne formulations.

Improved Ergonomics and Lightweight Design

Continuous improvements in material science and engineering will lead to even lighter and more ergonomically designed guns, further reducing operator fatigue and increasing precision.

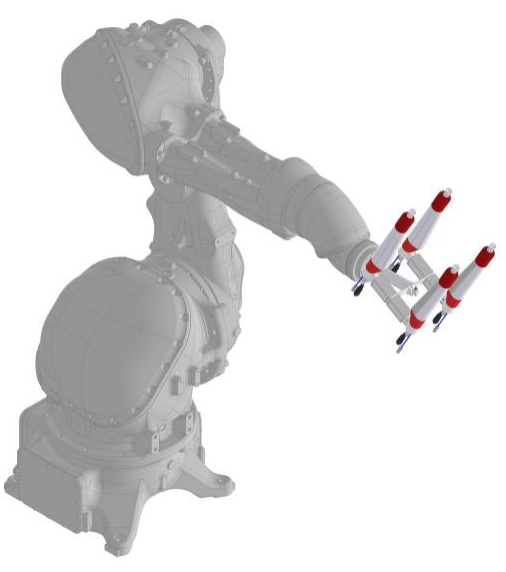

Automated and Robotic Integration

While this article focuses on manual guns, the underlying electrostatic technology is increasingly being integrated into automated and robotic systems, especially for high-volume production, further enhancing efficiency and consistency.

Conclusion

Manual electrostatic spray guns are indispensable tools for achieving high-quality, efficient, and environmentally responsible finishes across a broad spectrum of industries. Xinshunheng Industrial Co., Ltd. is committed to providing top-tier industrial solutions, and understanding the principles, operation, and maintenance of these guns is crucial for maximizing their potential. By leveraging the power of electrostatics, these tools not only enhance the aesthetic appeal and durability of products but also contribute to significant material savings and reduced environmental impact. Proper selection, operation, and diligent maintenance are key to unlocking the full benefits of this advanced coating technology.

Frequently Asked Questions

Q1: What is the main difference between a conventional spray gun and a manual electrostatic spray gun?

A1: The main difference lies in how paint particles are directed to the workpiece. Conventional guns rely solely on air pressure, while electrostatic guns also apply an electrical charge to the paint particles, causing them to be electrostatically attracted to the grounded workpiece, leading to higher transfer efficiency and a "wrap-around" effect.

Q2: Can manual electrostatic spray guns be used with any type of paint?

A2: While versatile, electrostatic spray guns are best suited for conductive or semi-conductive coatings. Special precautions and gun designs are required for highly conductive materials like waterborne paints to ensure proper insulation and safety. Powder coatings also require specific electrostatic powder guns.

Q3: Why is proper grounding important for electrostatic spray guns?

A3: Proper grounding of the workpiece is crucial because it creates the necessary potential difference (charge attraction) between the negatively charged paint particles and the workpiece. Without effective grounding, the electrostatic effect is significantly reduced or eliminated, leading to poor transfer efficiency and an inferior finish.

Q4: How does the "wrap-around" effect benefit the painting process?

A4: The "wrap-around" effect causes charged paint particles to be drawn to all accessible surfaces of the workpiece, including areas not directly in the spray path. This results in more uniform coverage on complex shapes, better edge coverage, and reduced overspray, saving material and improving overall finish quality.

Q5: What safety precautions should be taken when using a manual electrostatic spray gun?

A5: Operators should always wear appropriate personal protective equipment (PPE) including respirators, gloves, and protective clothing. It is critical to ensure the workpiece is properly grounded and to never touch the gun's electrode or the workpiece during operation due to the high voltage. The work area must be well-ventilated to prevent the buildup of flammable vapors.

Q6: How often should a manual electrostatic spray gun be cleaned?

A6: A manual electrostatic spray gun should be flushed and cleaned after every use, especially the fluid passages, nozzle, and air cap, to prevent paint buildup and clogging. More thorough cleaning, including disassembling the air cap and inspecting internal components, should be done weekly or monthly depending on usage frequency.

Q7: Can electrostatic spray guns save money?

A7: Yes, electrostatic spray guns can lead to significant cost savings. Their higher transfer efficiency means less coating material is wasted as overspray, resulting in substantial savings on paint costs. Additionally, reduced cleanup time and higher productivity further contribute to overall cost reduction.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.