Content Menu

● What is Electrostatic Powder Coating?

>> The Basics of Electrostatics

>> How Does Manual Electrostatic Powder Application Work?

>>> Key Components of the Process

● Advantages of Manual Electrostatic Powder Application

>> Enhanced Coating Efficiency

>> Environmentally Friendly

>> Durability and Performance

>> Versatility in Finishing

● Techniques for Manual Electrostatic Powder Application

>> Surface Preparation

>> Adjusting the Electrostatic Charge

>> Spray Technique

>> Curing Process

● Common Applications of Manual Electrostatic Powder Application

>> Automotive Industry

>> Furniture Manufacturing

>> Appliance Industry

>> Architectural Applications

>> Industrial Equipment

● Challenges in Manual Electrostatic Powder Application

>> Environmental Factors

>> Equipment Maintenance

>> Learning Curve

● Conclusion

>> Frequently Asked Questions

Electrostatic powder coating is a widely used technique in the manufacturing and finishing industries. This process involves applying a dry powder to a surface using electrostatic forces, which ensures an even and durable coating. In this article, we will delve into the science behind manual electrostatic powder application, exploring its principles, advantages, techniques, and common applications.

What is Electrostatic Powder Coating?

Electrostatic powder coating is a method of applying a protective and decorative finish to various substrates, including metals, plastics, and wood. The process involves charging the powder particles and using an electrostatic field to attract them to the grounded surface. This technique results in a uniform coating that adheres well and can be cured to form a hard, durable finish.

The Basics of Electrostatics

Electrostatics is the study of electric charges at rest. In the context of powder coating, it involves the generation of static electricity to charge the powder particles. When these charged particles are sprayed towards a grounded object, they are attracted to the surface, ensuring that the powder adheres evenly.

How Does Manual Electrostatic Powder Application Work?

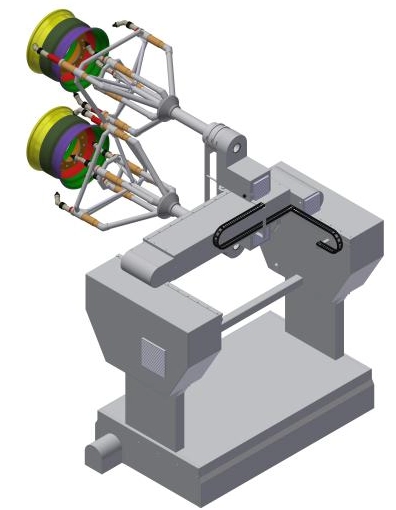

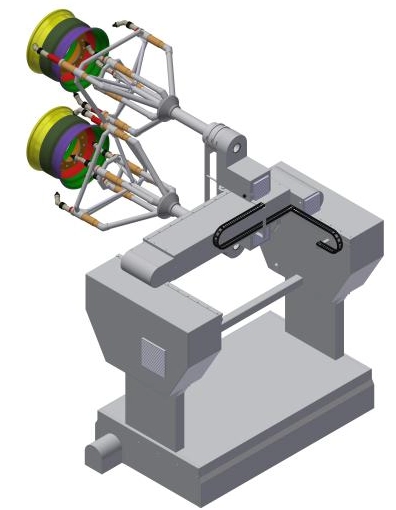

In manual electrostatic powder application, the operator uses a spray gun equipped with an electrostatic charging mechanism. The powder is fed into the gun, where it is charged as it passes through an electrode. The charged powder is then sprayed onto the workpiece, which is grounded to create an attractive force.

Key Components of the Process

1. Powder Coating Material: The powder used in this process is typically made from a mixture of resins, pigments, and additives. The choice of powder affects the final appearance and performance of the coating.

2. Electrostatic Spray Gun: This tool is essential for applying the powder. It charges the powder particles and allows for precise control over the application process.

3. Grounded Workpiece: The object being coated must be grounded to create an electrostatic field. This ensures that the charged powder particles are attracted to the surface, resulting in an even coating.

4. Curing Oven: After application, the coated workpiece is placed in a curing oven. The heat causes the powder to melt and flow, forming a smooth, durable finish.

Advantages of Manual Electrostatic Powder Application

Manual electrostatic powder application offers several advantages over traditional liquid coatings. Understanding these benefits can help manufacturers make informed decisions about their finishing processes.

Enhanced Coating Efficiency

One of the primary advantages of electrostatic powder coating is its efficiency. The electrostatic charge allows for better transfer efficiency, meaning more powder adheres to the surface rather than being wasted. This results in less overspray and reduced material costs.

Environmentally Friendly

Powder coatings are generally more environmentally friendly than liquid coatings. They contain no solvents, which means they emit fewer volatile organic compounds (VOCs) into the atmosphere. This makes them a safer choice for both workers and the environment.

Durability and Performance

Powder coatings are known for their durability. Once cured, they form a hard finish that is resistant to chipping, scratching, and fading. This makes them ideal for applications where the coated surface will be exposed to harsh conditions.

Versatility in Finishing

Electrostatic powder coating can be used on a wide variety of materials and surfaces. It is suitable for both indoor and outdoor applications, making it a versatile choice for manufacturers across different industries.

Techniques for Manual Electrostatic Powder Application

While the basic principles of manual electrostatic powder application are straightforward, mastering the technique requires practice and understanding of various factors that can affect the outcome.

Surface Preparation

Proper surface preparation is crucial for achieving a high-quality finish. The substrate must be clean, dry, and free of contaminants such as oil, dust, and rust. Common surface preparation methods include sandblasting, chemical cleaning, and mechanical abrasion.

Adjusting the Electrostatic Charge

The effectiveness of the electrostatic charge can be influenced by several factors, including the type of powder, humidity, and the distance between the spray gun and the workpiece. Operators must adjust the voltage settings on the spray gun to optimize the charge for the specific powder being used.

Spray Technique

The technique used during application can significantly impact the final result. Operators should maintain a consistent distance from the workpiece and move the spray gun in a smooth, even motion. Overlapping passes can help ensure complete coverage without leaving uncoated areas.

Curing Process

After application, the coated workpiece must be cured in an oven to achieve the desired properties. The curing temperature and time will vary depending on the type of powder used. It is essential to follow the manufacturer's recommendations to ensure optimal results.

Common Applications of Manual Electrostatic Powder Application

Manual electrostatic powder application is used in various industries, each benefiting from the unique properties of powder coatings.

Automotive Industry

In the automotive sector, powder coatings are used for both functional and decorative purposes. They provide a durable finish for wheels, chassis components, and body panels, enhancing both appearance and corrosion resistance.

Furniture Manufacturing

Powder coating is popular in furniture manufacturing due to its ability to create a wide range of colors and finishes. It is commonly used on metal furniture, providing a tough, attractive surface that withstands daily use.

Appliance Industry

Household appliances, such as refrigerators and washing machines, often feature powder-coated surfaces. This not only improves aesthetics but also protects against scratches and corrosion.

Architectural Applications

In architecture, powder coatings are used on window frames, railings, and other exterior elements. The durability and weather resistance of powder coatings make them ideal for outdoor applications.

Industrial Equipment

Many industrial components, such as machinery and tools, are powder coated to enhance their durability and resistance to wear. This is particularly important in environments where equipment is subjected to harsh conditions.

Challenges in Manual Electrostatic Powder Application

While manual electrostatic powder application offers numerous benefits, it is not without its challenges. Understanding these challenges can help operators improve their processes and outcomes.

Environmental Factors

Humidity and temperature can significantly affect the electrostatic application process. High humidity can lead to poor powder adhesion, while low humidity can cause the powder to become too dry, resulting in a rough finish. Operators must monitor environmental conditions and adjust their techniques accordingly.

Equipment Maintenance

Regular maintenance of the spray gun and other equipment is essential for consistent performance. Clogged nozzles or worn components can lead to uneven application and increased waste. Operators should follow a routine maintenance schedule to ensure optimal operation.

Learning Curve

Mastering manual electrostatic powder application requires practice and experience. New operators may struggle with achieving consistent results initially. Providing training and resources can help improve their skills and confidence.

Conclusion

Manual electrostatic powder application is a sophisticated process that combines the principles of electrostatics with practical application techniques. By understanding the science behind this method, manufacturers can take advantage of its numerous benefits, including efficiency, environmental friendliness, and durability. As industries continue to evolve, the demand for high-quality finishes will only increase, making electrostatic powder coating an essential technique in modern manufacturing.

Frequently Asked Questions

1. What types of materials can be powder coated?

- Powder coating can be applied to metals, plastics, and wood, making it versatile for various applications.

2. How does powder coating compare to liquid painting?

- Powder coating is generally more efficient, environmentally friendly, and durable than liquid painting, with less overspray and no solvents.

3. What is the curing process for powder coatings?

- After application, powder-coated items are placed in a curing oven where heat causes the powder to melt and form a hard finish.

4. Can powder coatings be applied indoors?

- Yes, powder coatings can be applied indoors, but proper ventilation is essential to ensure safety and comfort.

5. What are the common challenges in powder coating?

- Challenges include environmental factors like humidity, equipment maintenance, and the learning curve for new operators.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.