Content Menu

● Understanding Electrostatic Spray Gun Technology

>> How Electrostatic Spray Guns Work

● Key Trends in Electrostatic Spray Gun Technology

>> 1. Automation and Robotics Integration

>>> Benefits of Automation

>> 2. Smart Technologies and IoT Integration

>>> Advantages of Smart Technologies

>> 3. Eco-Friendly Innovations

>>> Impact on Sustainability

>> 4. Ergonomic Design Improvements

>>> Features of Ergonomic Designs

>> 5. Advanced Nozzle Technologies

>>> Benefits of Advanced Nozzle Technologies

● Future Outlook for Electrostatic Spray Gun Technology

>> Challenges and Opportunities

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using electrostatic spray guns?

>> 2. How does automation impact the use of electrostatic spray guns?

>> 3. What role do smart technologies play in electrostatic spray guns?

>> 4. Are there any environmental benefits to using electrostatic spray guns?

>> 5. What should companies consider when investing in electrostatic spray gun technology?

Electrostatic spray guns have revolutionized the painting and coating industries by providing efficient, high-quality finishes with minimal waste. As technology continues to evolve, several trends are shaping the future of electrostatic spray guns. This article explores these trends, their implications for various industries, and the future of electrostatic spray technology.

Understanding Electrostatic Spray Gun Technology

Electrostatic spray guns utilize an electrical charge to attract paint particles to a grounded surface. This process enhances the efficiency of paint application, reduces overspray, and ensures a more uniform finish. The technology is widely used in industries such as automotive, aerospace, furniture manufacturing, and metal finishing.

How Electrostatic Spray Guns Work

Electrostatic spray guns operate by charging the paint particles as they exit the nozzle. The charged particles are then attracted to the grounded surface, allowing for a more efficient transfer of paint. This method not only minimizes waste but also improves the quality of the finish, making it a preferred choice for many applications.

Key Trends in Electrostatic Spray Gun Technology

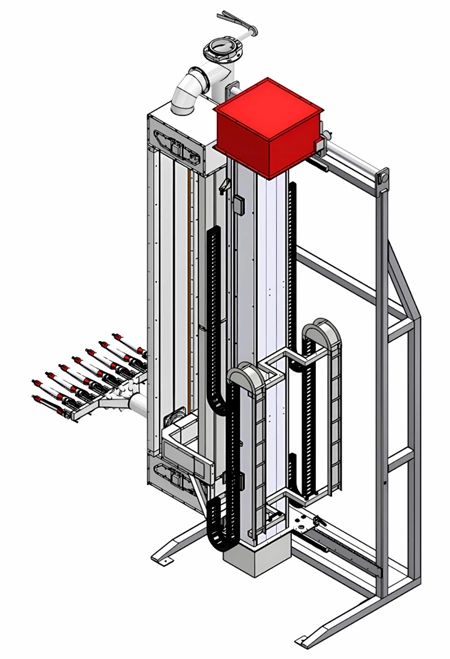

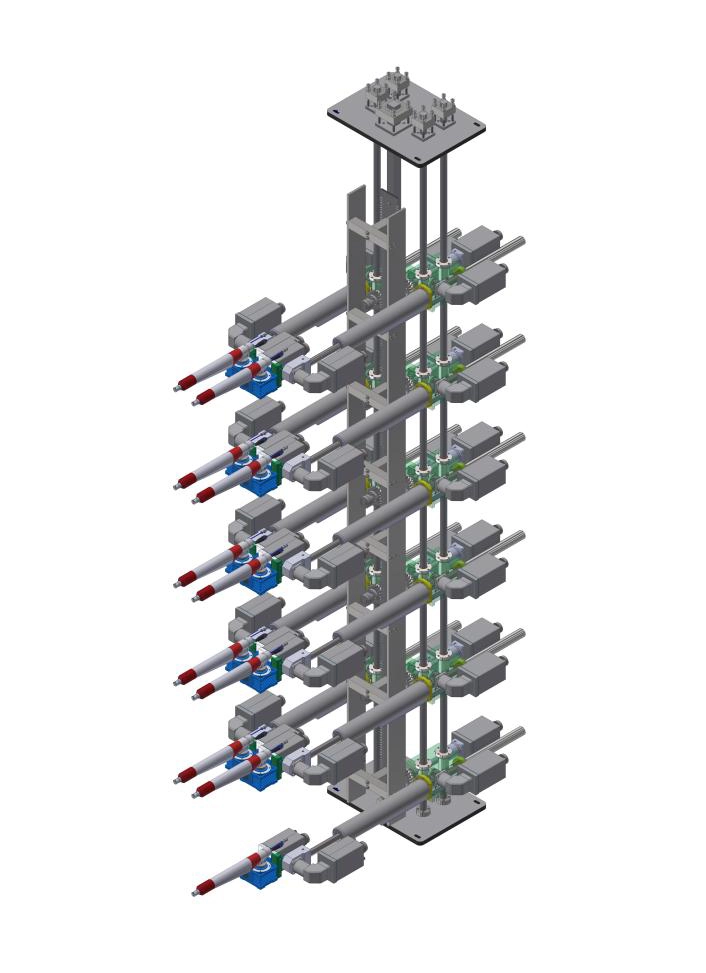

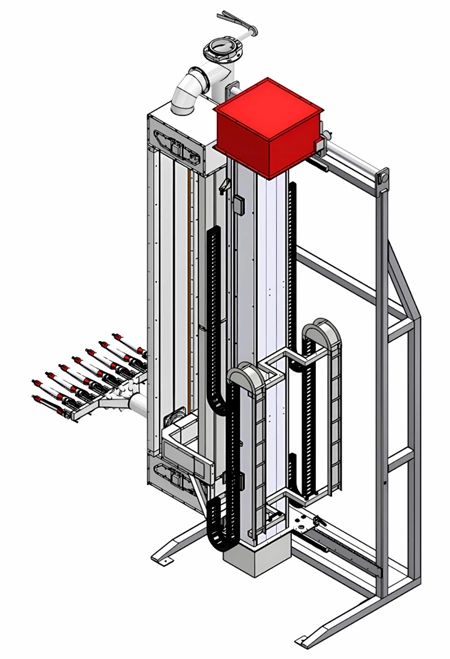

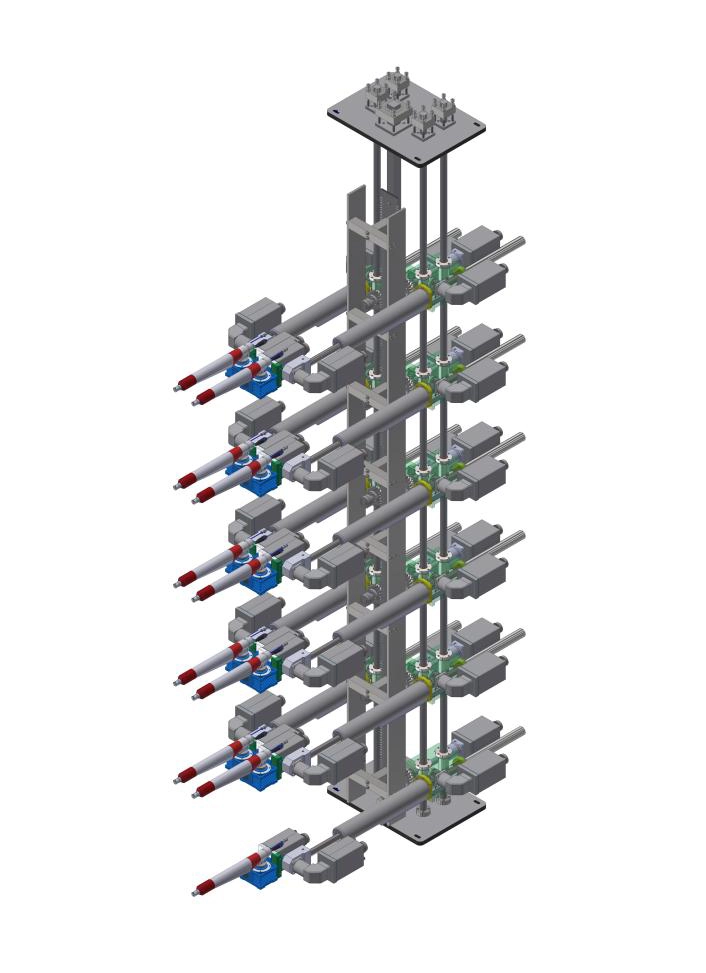

1. Automation and Robotics Integration

One of the most significant trends in electrostatic spray gun technology is the integration of automation and robotics. Manufacturers are increasingly incorporating electrostatic spray guns into robotic systems, which enhances productivity and consistency in coating applications. This trend is particularly evident in the automotive and aerospace industries, where precision and efficiency are paramount.

Benefits of Automation

- Increased Efficiency: Automated systems can operate continuously, reducing downtime and increasing output.

- Consistency: Robots provide uniform application, ensuring that every part receives the same quality of finish.

- Cost Reduction: Automation can lower labor costs and reduce material waste, leading to significant savings.

2. Smart Technologies and IoT Integration

The rise of smart technologies and the Internet of Things (IoT) is transforming electrostatic spray gun technology. Manufacturers are now integrating sensors and data analytics into their systems, allowing for real-time monitoring and optimization of the spraying process.

Advantages of Smart Technologies

- Real-Time Monitoring: Sensors can track parameters such as voltage, fluid flow, and environmental conditions, enabling adjustments on the fly.

- Predictive Maintenance: Data analytics can predict when maintenance is needed, reducing downtime and extending the lifespan of equipment.

- Enhanced Control: Operators can remotely control and adjust settings, improving flexibility and responsiveness.

3. Eco-Friendly Innovations

As environmental concerns grow, the demand for eco-friendly coatings and processes is increasing. Electrostatic spray guns are at the forefront of this trend, with manufacturers developing systems that use low-VOC (volatile organic compounds) and water-based paints.

Impact on Sustainability

- Reduced Emissions: Eco-friendly paints contribute to lower emissions, aligning with regulatory standards and consumer preferences.

- Waste Reduction: The efficiency of electrostatic spray guns minimizes overspray, leading to less waste and a smaller environmental footprint.

- Sustainable Practices: Companies adopting these technologies can enhance their sustainability profiles, appealing to environmentally conscious consumers.

4. Ergonomic Design Improvements

The design of electrostatic spray guns is evolving to enhance operator comfort and safety. Manufacturers are focusing on ergonomics to reduce fatigue and improve usability.

Features of Ergonomic Designs

- Lightweight Materials: Using lighter materials reduces strain on operators during extended use.

- Adjustable Handles: Ergonomic handles can be adjusted to fit the operator's hand size, improving comfort and control.

- Reduced Vibration: Advanced designs minimize vibration, further enhancing operator comfort and reducing fatigue.

5. Advanced Nozzle Technologies

Innovations in nozzle design are also shaping the future of electrostatic spray guns. New nozzle technologies improve atomization and spray patterns, leading to better coverage and finish quality.

Benefits of Advanced Nozzle Technologies

- Improved Atomization: Enhanced nozzle designs create finer paint particles, resulting in a smoother finish.

- Versatile Spray Patterns: Adjustable nozzles allow operators to switch between different spray patterns, accommodating various applications.

- Increased Transfer Efficiency: Advanced nozzles can achieve higher transfer efficiency, reducing material waste and improving cost-effectiveness.

Future Outlook for Electrostatic Spray Gun Technology

The future of electrostatic spray gun technology looks promising, with continued advancements expected in automation, smart technologies, and eco-friendly practices. As industries increasingly prioritize efficiency and sustainability, electrostatic spray guns will play a crucial role in meeting these demands.

Challenges and Opportunities

While the trends are encouraging, challenges remain. The initial investment in advanced systems can be high, and training operators to use new technologies effectively is essential. However, the long-term benefits, including cost savings and improved quality, often outweigh these challenges.

Conclusion

Electrostatic spray gun technology is evolving rapidly, driven by automation, smart technologies, and a focus on sustainability. As industries continue to adopt these innovations, the efficiency and quality of coating applications will improve, paving the way for a more sustainable future in manufacturing and beyond.

Frequently Asked Questions

1. What are the main advantages of using electrostatic spray guns?

Electrostatic spray guns offer several advantages, including reduced overspray, improved transfer efficiency, and a more uniform finish. They also minimize waste and can be used with eco-friendly paints.

2. How does automation impact the use of electrostatic spray guns?

Automation enhances the efficiency and consistency of coating applications. Robotic systems can operate continuously, reducing labor costs and ensuring uniform application across all parts.

3. What role do smart technologies play in electrostatic spray guns?

Smart technologies enable real-time monitoring and optimization of the spraying process. Sensors and data analytics help operators adjust settings on the fly, improving efficiency and quality.

4. Are there any environmental benefits to using electrostatic spray guns?

Yes, electrostatic spray guns can use low-VOC and water-based paints, reducing emissions and waste. Their efficiency also minimizes overspray, contributing to a smaller environmental footprint.

5. What should companies consider when investing in electrostatic spray gun technology?

Companies should evaluate the initial investment costs, the potential for long-term savings, and the training required for operators. Additionally, they should consider the specific needs of their applications and the benefits of automation and smart technologies.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.