Content Menu

● Introduction

● Understanding Powder Sieves

>> What is a Powder Sieve?

>> Importance of Powder Sieving

● Leading Powder Sieve Manufacturers in Myanmar

>> 1. Ramseier Koatings Technologies Holdings Ltd.

>> 2. Nakagawa Chemical Equipment Myanmar Co., Ltd.

>> 3. Kason Corporation

>> 4. Farleygreene

>> 5. Piab

● Applications of Powder Sieves

>> Pharmaceutical Industry

>> Food Processing

>> Chemical Manufacturing

● Benefits of Using Powder Sieves

>> Enhanced Product Quality

>> Increased Efficiency

>> Cost-Effectiveness

● Frequently Asked Questions

>> 1. What types of materials can be processed with powder sieves?

>> 2. How do I choose the right powder sieve for my application?

>> 3. What maintenance is required for powder sieves?

>> 4. Can powder sieves be customized?

>> 5. What are the safety considerations when using powder sieves?

● Conclusion

Introduction

In the rapidly evolving industrial landscape, the demand for efficient powder sieving solutions has surged. This article explores the top powder sieve manufacturers and suppliers in Myanmar, highlighting their contributions to the industry. Among these, Ramseier Koatings Technologies Holdings Ltd. stands out as a leading provider, known for its innovative powder sieve systems. This comprehensive guide will delve into the features, benefits, and applications of powder sieves, while also addressing common questions related to this essential equipment.

Understanding Powder Sieves

What is a Powder Sieve?

A powder sieve is a crucial piece of equipment used in various industries to separate and classify powders based on particle size. It ensures that the final product meets quality standards by removing oversized particles and contaminants. The efficiency of powder sieves directly impacts production quality and operational efficiency.

Importance of Powder Sieving

The importance of powder sieving cannot be overstated. It plays a vital role in:

- Quality Control: Ensuring uniformity in product size and composition.

- Process Efficiency: Reducing waste and improving throughput.

- Safety: Minimizing the risk of contamination in sensitive applications.

Leading Powder Sieve Manufacturers in Myanmar

1. Ramseier Koatings Technologies Holdings Ltd.

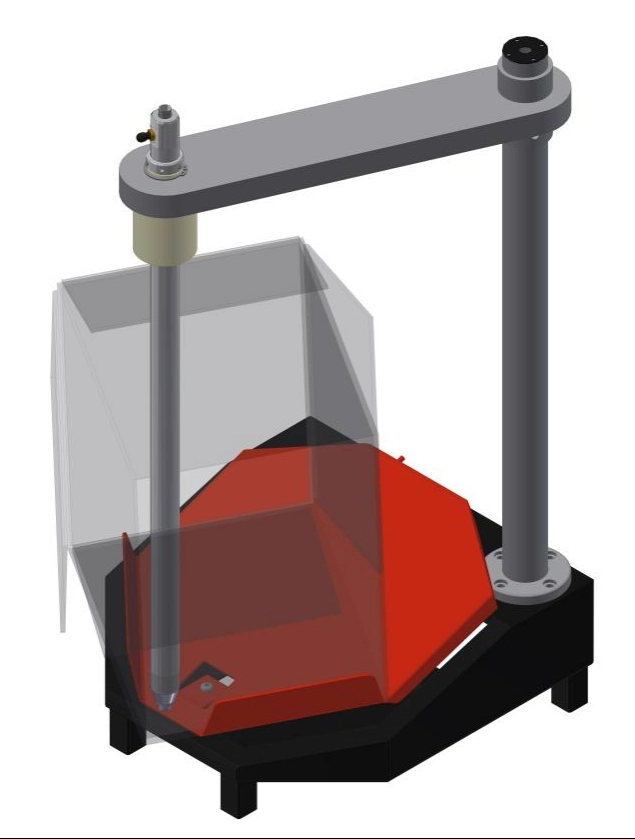

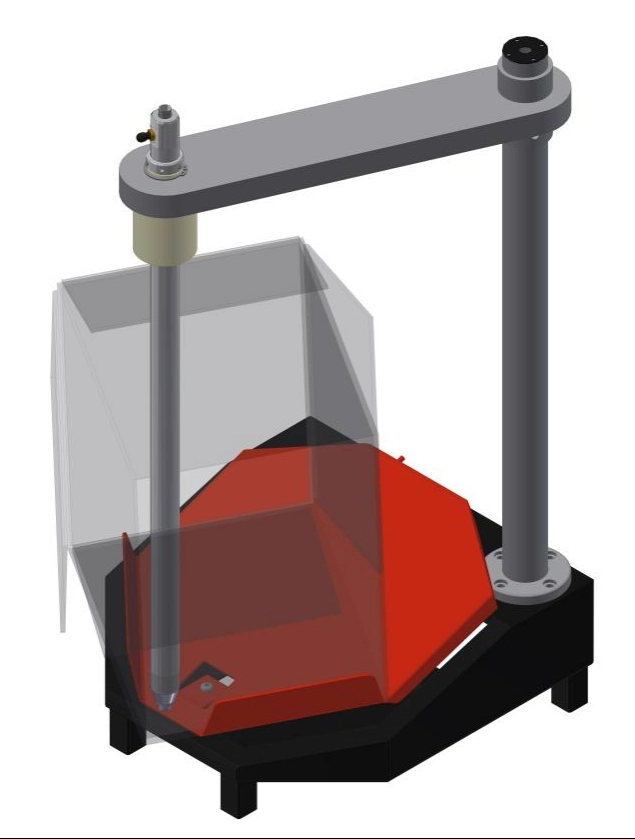

Ramseier Koatings Technologies Holdings Ltd. is at the forefront of powder sieve manufacturing in Myanmar. The company specializes in custom powder sieve systems designed to meet the specific needs of various industries, including pharmaceuticals, food processing, and chemicals. Their products are known for:

- High Efficiency: Advanced designs that maximize throughput.

- Durability: Built with high-quality materials to withstand rigorous use.

- Easy Maintenance: Features that allow for quick cleaning and replacement of components.

2. Nakagawa Chemical Equipment Myanmar Co., Ltd.

Nakagawa Chemical Equipment is another prominent player in the Myanmar market. They offer a range of powder sieving solutions tailored to local standards. Their focus on maintenance and after-sales service ensures that clients receive ongoing support.

3. Kason Corporation

Kason Corporation manufactures a variety of powder processing equipment, including static scalping sieves. Their products are designed for continuous scalping applications, making them ideal for industries that require high efficiency and reliability.

4. Farleygreene

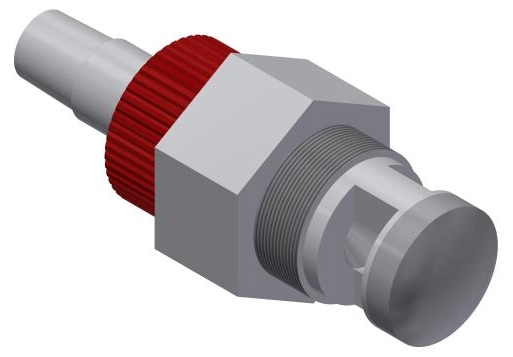

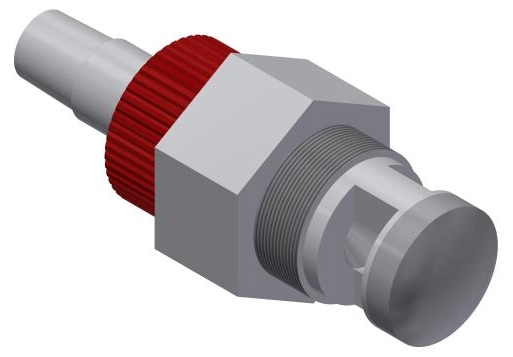

Farleygreene specializes in automated sieving solutions, particularly for metal powders. Their innovative designs incorporate ultrasonic technology, which enhances the efficiency of the sieving process and reduces downtime.

5. Piab

Piab offers comprehensive solutions for powder handling, including sieve stations that integrate seamlessly with their vacuum conveyor systems. Their focus on automation and efficiency makes them a key player in the powder processing industry.

Applications of Powder Sieves

Pharmaceutical Industry

In the pharmaceutical sector, powder sieves are essential for ensuring the quality and consistency of active ingredients. They help in the production of tablets and capsules by ensuring that the powders used are of the correct size and free from contaminants.

Food Processing

In food processing, powder sieves are used to ensure that ingredients like flour, sugar, and spices are free from lumps and foreign materials. This not only improves product quality but also enhances safety for consumers.

Chemical Manufacturing

Chemical manufacturers rely on powder sieves to maintain the quality of their products. By removing oversized particles, they can ensure that their chemicals meet the required specifications for various applications.

Benefits of Using Powder Sieves

Enhanced Product Quality

Using a powder sieve significantly enhances product quality by ensuring uniform particle size and removing impurities. This is crucial for industries where precision is paramount.

Increased Efficiency

Powder sieves improve operational efficiency by streamlining the production process. They reduce the need for manual sorting and handling, allowing for faster production cycles.

Cost-Effectiveness

Investing in high-quality powder sieves can lead to long-term cost savings. By minimizing waste and improving product quality, companies can reduce their overall production costs.

Frequently Asked Questions

1. What types of materials can be processed with powder sieves?

Powder sieves can process a wide range of materials, including metals, plastics, food ingredients, and pharmaceuticals. The specific type of sieve may vary based on the material's properties.

2. How do I choose the right powder sieve for my application?

Choosing the right powder sieve depends on factors such as the type of material, desired particle size, and production volume. Consulting with manufacturers can help identify the best solution.

3. What maintenance is required for powder sieves?

Regular maintenance includes cleaning the sieve screens, checking for wear and tear, and ensuring that all components are functioning correctly. This helps maintain efficiency and prolongs the equipment's lifespan.

4. Can powder sieves be customized?

Yes, many manufacturers, including Ramseier Koatings, offer customization options to meet specific industry needs and requirements.

5. What are the safety considerations when using powder sieves?

Safety considerations include ensuring that the equipment is properly grounded, using protective gear when handling powders, and following manufacturer guidelines for operation and maintenance.

Conclusion

In conclusion, the demand for efficient powder sieving solutions is on the rise, and companies like Ramseier Koatings Technologies Holdings Ltd. are leading the way in Myanmar. With a focus on quality, efficiency, and customer support, these manufacturers are well-equipped to meet the needs of various industries. By understanding the importance of powder sieves and their applications, businesses can enhance their production processes and ensure the highest quality standards.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.