Content Menu

● Introduction

● Ramseier Koatings Technologies Holdings Ltd.

>> Overview

>> Key Products

>> Applications

● Other Notable Powder Sieve Manufacturers in Latvia

>> 1. Kason Corporation

>> 2. Palamatic Process

>> 3. Farley Greene

>> 4. Quadro Engineering

● The Importance of Powder Sieves

>> Quality Control

>> Efficiency in Production

>> Versatility

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What is a powder sieve?

>> 2. Why is powder sieving important in pharmaceuticals?

>> 3. What types of powder sieves are available?

>> 4. How does a vibratory sieve work?

>> 5. Can powder sieves be customized for specific applications?

Introduction

In the realm of powder processing, the efficiency and quality of production heavily rely on the effectiveness of powder sieves. These essential tools are utilized across various industries, including pharmaceuticals, food processing, and chemical manufacturing. This article explores the top powder sieve manufacturers and suppliers in Latvia, with a special focus on Ramseier Koatings Technologies Holdings Ltd., a leader in the field. We will delve into the significance of powder sieves, the innovative technologies employed by these manufacturers, and the diverse applications of their products.

Ramseier Koatings Technologies Holdings Ltd.

Overview

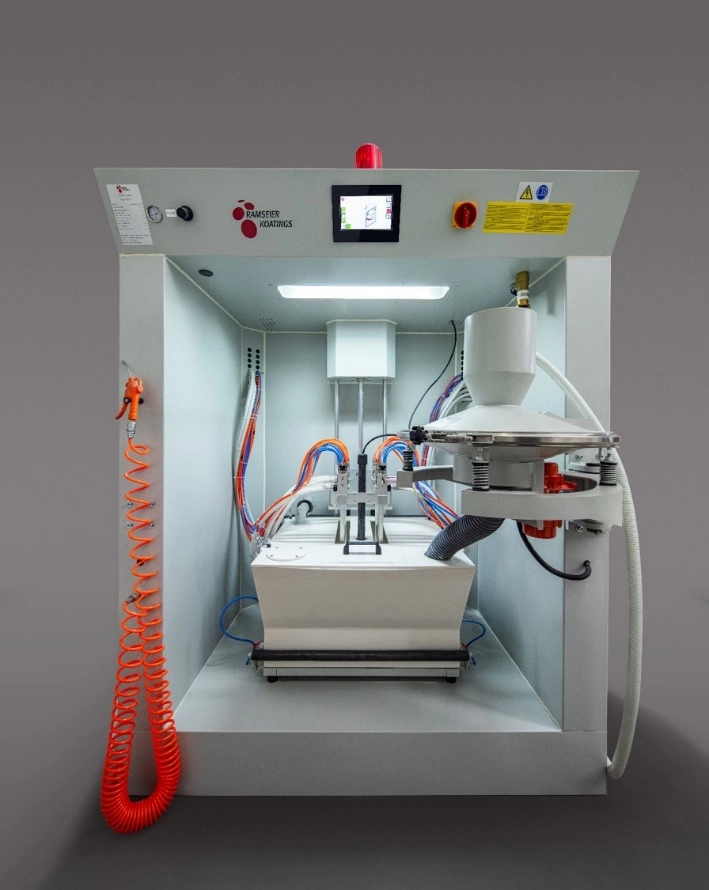

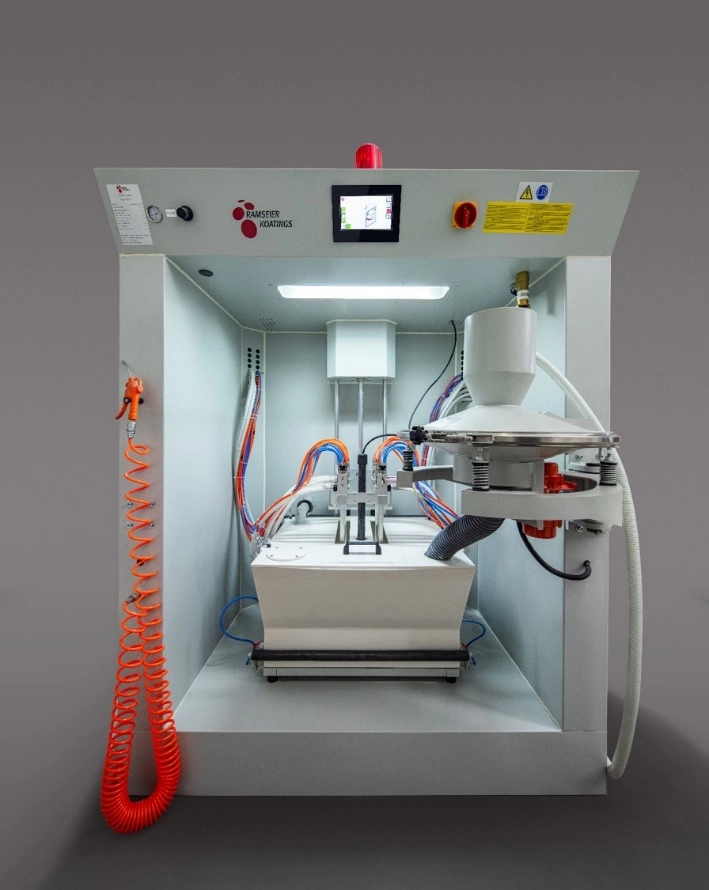

Ramseier Koatings Technologies Holdings Ltd. stands out as a premier manufacturer of powder sieving equipment in Latvia. With a commitment to quality and innovation, the company specializes in providing tailored solutions for various industries. Their advanced powder sieving technologies ensure optimal performance, enhancing production efficiency and product quality.

Key Products

1. Vibratory Sieves: These sieves utilize vibration to separate particles based on size, ensuring a consistent and high-quality output.

2. Ultrasonic Sieves: By employing ultrasonic technology, these sieves prevent blinding and improve the flow of fine powders.

3. Rotary Sieves: Ideal for bulk processing, rotary sieves offer high throughput and are designed for continuous operation.

Applications

Ramseier's powder sieves are widely used in:

- Pharmaceuticals: Ensuring the purity and consistency of active ingredients.

- Food Processing: Removing contaminants and ensuring product quality.

- Chemical Manufacturing: Facilitating the production of fine powders and granules.

Other Notable Powder Sieve Manufacturers in Latvia

1. Kason Corporation

Kason Corporation is renowned for its innovative powder processing equipment. Their CROSS-FLO static scalping sieves are designed to remove oversized particles from dry bulk solids, making them ideal for continuous scalping applications. Kason's commitment to quality and efficiency has made them a trusted name in the industry.

2. Palamatic Process

Palamatic Process offers a comprehensive range of industrial screening solutions, including centrifugal screens that control and protect production lines. Their equipment is designed to eliminate foreign bodies and reduce aggregates, ensuring the highest quality of powder products.

3. Farley Greene

Farley Greene specializes in automated powder sieving solutions, such as the Sievgen 04-S. This equipment is particularly effective in validating additive powders used in various industries, including food and pharmaceuticals. Their focus on automation enhances efficiency and reduces manual labor.

4. Quadro Engineering

Quadro Engineering is known for its FlexSift technology, which provides efficient powder sieving and sifting. This equipment is designed to handle a wide range of applications, ensuring that only uniform particles enter the processing stream.

The Importance of Powder Sieves

Quality Control

Powder sieves play a crucial role in maintaining quality control across various industries. By effectively separating particles based on size, these devices ensure that only the desired particle sizes are used in production. This is particularly important in industries like pharmaceuticals, where the efficacy of a product can be significantly affected by particle size.

Efficiency in Production

The use of advanced powder sieving technologies can greatly enhance production efficiency. For instance, vibratory and ultrasonic sieves can process large volumes of powder quickly, reducing downtime and increasing throughput. This efficiency is vital for manufacturers looking to meet high demand while maintaining quality standards.

Versatility

Powder sieves are versatile tools that can be adapted for various applications. Whether in food processing, pharmaceuticals, or chemical manufacturing, these devices can be customized to meet specific needs. This adaptability makes them indispensable in modern manufacturing processes.

Conclusion

In conclusion, the landscape of powder sieve manufacturing in Latvia is marked by innovation and quality. Ramseier Koatings Technologies Holdings Ltd. leads the way with its advanced technologies and commitment to excellence. Other notable manufacturers, such as Kason Corporation, Palamatic Process, Farley Greene, and Quadro Engineering, also contribute significantly to the industry. As the demand for high-quality powder processing continues to grow, these companies are well-positioned to meet the needs of various sectors.

Frequently Asked Questions (FAQs)

1. What is a powder sieve?

A powder sieve is a device used to separate particles based on size, ensuring that only the desired particle sizes are used in production processes.

2. Why is powder sieving important in pharmaceuticals?

Powder sieving is crucial in pharmaceuticals to ensure the purity and consistency of active ingredients, which can significantly affect the efficacy of the final product.

3. What types of powder sieves are available?

Common types of powder sieves include vibratory sieves, ultrasonic sieves, and rotary sieves, each designed for specific applications and efficiency.

4. How does a vibratory sieve work?

A vibratory sieve uses vibration to cause particles to pass through apertures in the screen, effectively separating them based on size.

5. Can powder sieves be customized for specific applications?

Yes, many manufacturers offer customizable powder sieving solutions to meet the unique needs of different industries and applications.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.