Content Menu

● Introduction

● 1. Ramseier Koatings Technologies Holdings Ltd.

>> Overview

>> Key Features of Ramseier Spray Guns

● 2. Graco Inc.

>> Overview

>> Key Features of Graco Spray Guns

● 3. Binks

>> Overview

>> Key Features of Binks Spray Guns

● 4. Wagner Group

>> Overview

>> Key Features of Wagner Spray Guns

● 5. JOBON

>> Overview

>> Key Features of JOBON Spray Guns

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What is an electrostatic spray gun?

>> 2. How does an electrostatic spray gun work?

>> 3. What are the benefits of using electrostatic spray guns?

>> 4. Can electrostatic spray guns be used for both liquid and powder coatings?

>> 5. How do I choose the right electrostatic spray gun for my needs?

● Article Summary

Introduction

In the world of industrial coating, electrostatic spray guns have revolutionized the way coatings are applied. These tools not only enhance efficiency but also improve the quality of finishes. Slovenia, with its growing manufacturing sector, is home to several top manufacturers and suppliers of electrostatic spray guns. This article will explore the leading companies in this field, with a special focus on Ramseier Koatings Technologies Holdings Ltd., a pioneer in the industry.

1. Ramseier Koatings Technologies Holdings Ltd.

Overview

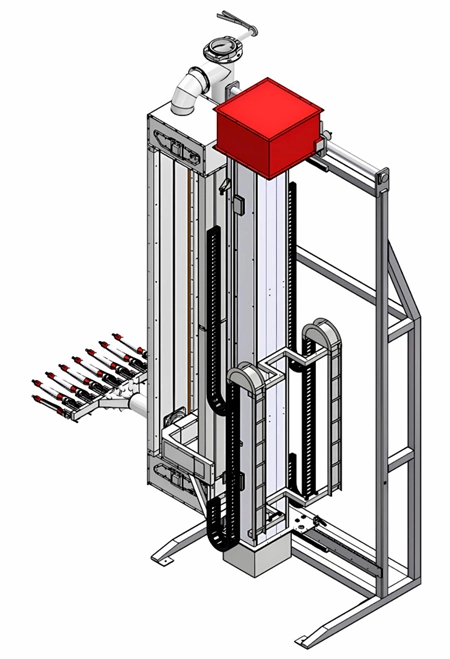

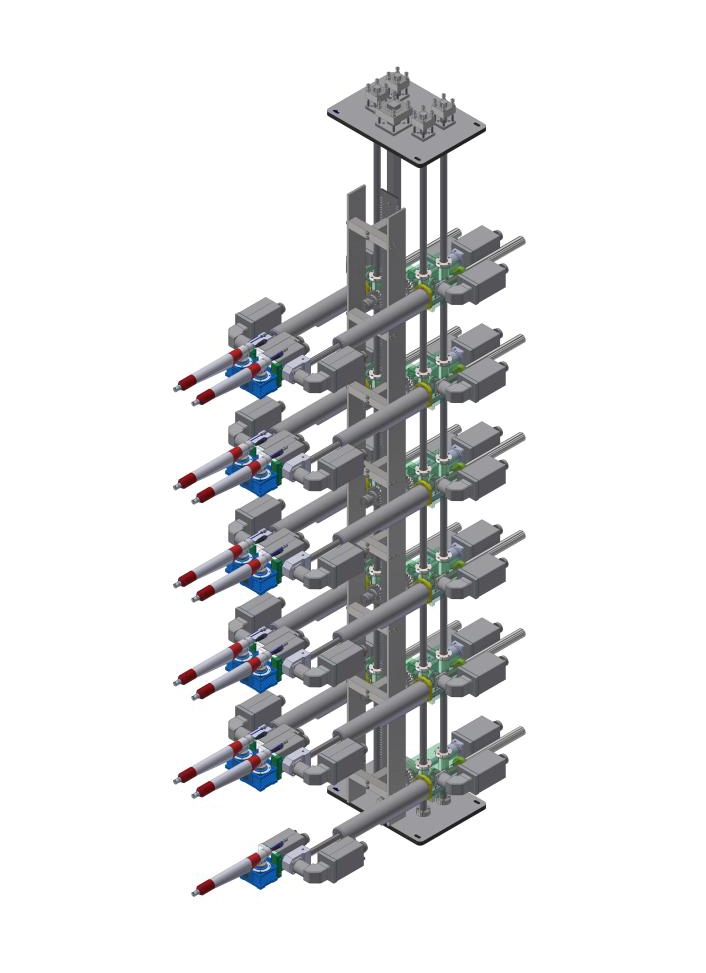

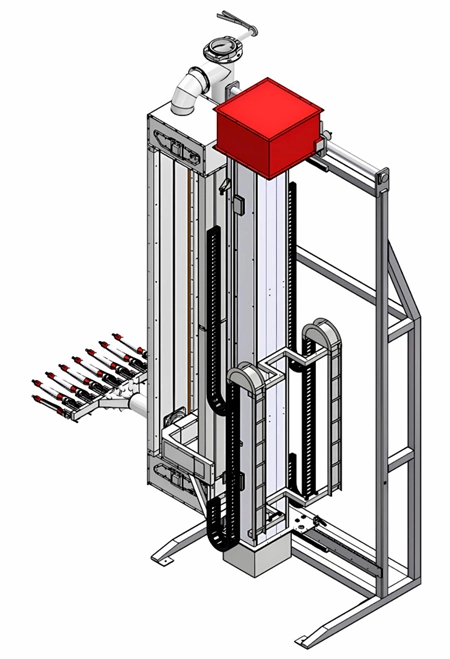

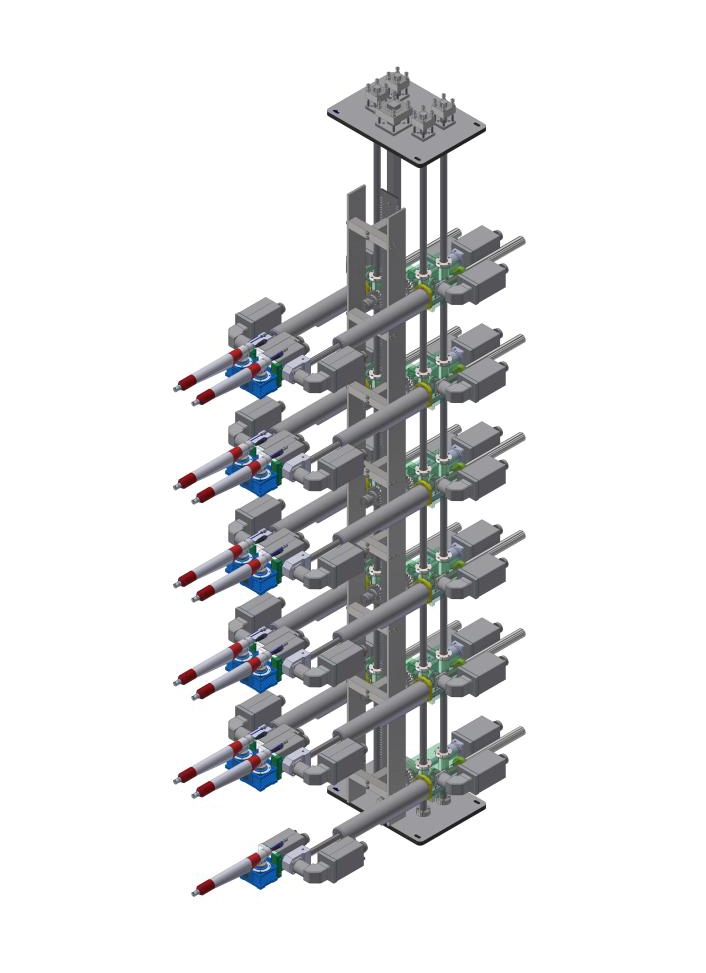

Ramseier Koatings Technologies Holdings Ltd. stands at the forefront of electrostatic spray gun technology. With a commitment to innovation and quality, this company has established itself as a leader in the manufacturing of electrostatic spray guns. Their products are designed to meet the diverse needs of various industries, including automotive, furniture, and metal finishing.

Key Features of Ramseier Spray Guns

- High Efficiency: Ramseier's electrostatic spray guns are engineered to maximize transfer efficiency, reducing material waste and improving productivity.

- Versatility: These spray guns can handle a wide range of coatings, including powders and liquids, making them suitable for various applications.

- User-Friendly Design: The ergonomic design of Ramseier spray guns ensures ease of use, allowing operators to work comfortably for extended periods.

2. Graco Inc.

Overview

Graco Inc. is another prominent player in the electrostatic spray gun market. Known for its high-quality products, Graco offers a range of electrostatic spray guns that cater to different industrial needs.

Key Features of Graco Spray Guns

- Advanced Technology: Graco's electrostatic spray guns utilize cutting-edge technology to ensure precise application and minimal overspray.

- Durability: Built to withstand the rigors of industrial use, Graco spray guns are known for their longevity and reliability.

- Comprehensive Support: Graco provides extensive customer support and training, ensuring that users can maximize the potential of their spray guns.

3. Binks

Overview

Binks, a brand under the ITW (Illinois Tool Works) umbrella, has a long history in the spray gun industry. Their electrostatic spray guns are widely recognized for their performance and reliability.

Key Features of Binks Spray Guns

- Innovative Design: Binks spray guns feature innovative designs that enhance performance and ease of use.

- Wide Range of Applications: Suitable for various coatings, Binks spray guns are ideal for both small and large-scale operations.

- Expertise in Coating Solutions: With decades of experience, Binks offers expert advice and solutions tailored to specific coating needs.

4. Wagner Group

Overview

Wagner Group is a global leader in coating technology, offering a comprehensive range of electrostatic spray guns. Their products are designed for both professional and industrial applications.

Key Features of Wagner Spray Guns

- Precision Engineering: Wagner spray guns are engineered for precision, ensuring consistent application and high-quality finishes.

- Eco-Friendly Solutions: Wagner is committed to sustainability, offering eco-friendly spray gun options that reduce environmental impact.

- Global Reach: With a presence in multiple countries, Wagner provides localized support and service to its customers.

5. JOBON

Overview

JOBON is a rising star in the electrostatic spray gun market, known for its cost-effective solutions and innovative technology.

Key Features of JOBON Spray Guns

- Affordable Pricing: JOBON offers competitive pricing without compromising on quality, making their spray guns accessible to a wider audience.

- User-Friendly Features: Designed with the user in mind, JOBON spray guns are easy to operate and maintain.

- Strong Market Presence: With a growing reputation, JOBON is expanding its reach in international markets, including Slovenia.

Conclusion

The electrostatic spray gun market in Slovenia is thriving, with several manufacturers leading the way in innovation and quality. Ramseier Koatings Technologies Holdings Ltd. is at the forefront, offering advanced solutions that cater to various industrial needs. Other notable companies like Graco, Binks, Wagner, and JOBON also contribute significantly to the market, providing a range of options for businesses looking to enhance their coating processes.

Frequently Asked Questions (FAQs)

1. What is an electrostatic spray gun?

An electrostatic spray gun is a device that applies a charged coating material to a surface, ensuring a more efficient and uniform application.

2. How does an electrostatic spray gun work?

The spray gun charges the coating particles, which are then attracted to the grounded surface, reducing overspray and improving transfer efficiency.

3. What are the benefits of using electrostatic spray guns?

Benefits include reduced material waste, improved finish quality, and the ability to coat complex shapes and surfaces effectively.

4. Can electrostatic spray guns be used for both liquid and powder coatings?

Yes, many electrostatic spray guns are designed to handle both liquid and powder coatings, making them versatile tools for various applications.

5. How do I choose the right electrostatic spray gun for my needs?

Consider factors such as the type of coating, the size of the project, and the specific requirements of your application when selecting a spray gun.

Article Summary

This article explored the top electrostatic spray gun manufacturers and suppliers in Slovenia, highlighting Ramseier Koatings Technologies Holdings Ltd. as a leader in the industry. Other notable companies include Graco, Binks, Wagner, and JOBON, each offering unique features and benefits. The article also provided insights into the workings and advantages of electrostatic spray guns, along with a FAQ section addressing common queries.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.