Content Menu

● Introduction

● 1. Ramseier Koatings Technologies Holdings Ltd.

>> Overview

>> Key Features

● 2. Nordson Corporation

>> Overview

>> Key Features

● 3. Graco Inc.

>> Overview

>> Key Features

● 4. Binks

>> Overview

>> Key Features

● 5. Sames Kremlin

>> Overview

>> Key Features

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What is an electrostatic spray gun?

>> 2. How does an electrostatic spray gun work?

>> 3. What are the benefits of using electrostatic spray guns?

>> 4. Can electrostatic spray guns be used for all types of coatings?

>> 5. How do I choose the right electrostatic spray gun for my needs?

Introduction

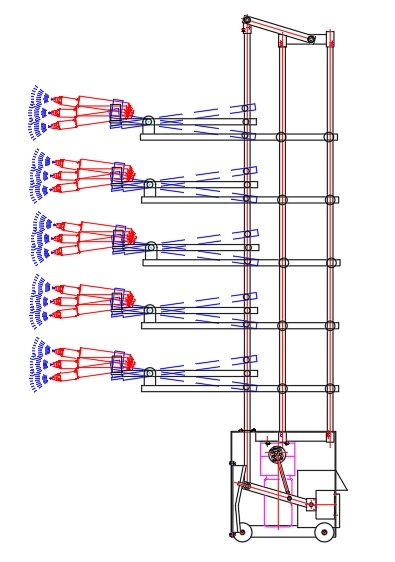

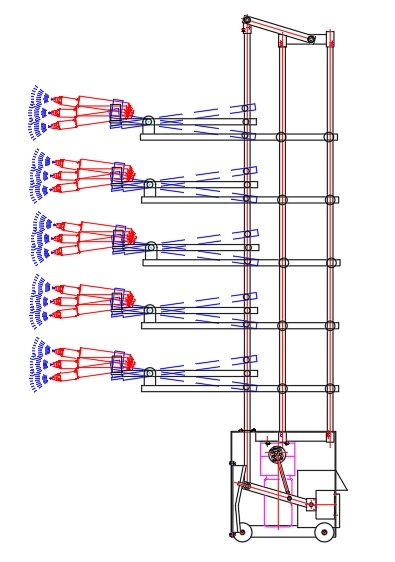

In the world of industrial coating, electrostatic spray guns have become essential tools for achieving high-quality finishes with minimal waste. This article explores the top manufacturers and suppliers of electrostatic spray guns in Romania, highlighting their unique offerings and contributions to the industry. Among these, Ramseier Koatings Technologies Holdings Ltd. stands out as a leader in providing innovative solutions for various coating applications.

1. Ramseier Koatings Technologies Holdings Ltd.

Overview

Ramseier Koatings Technologies Holdings Ltd. is renowned for its advanced electrostatic spray gun technology. The company specializes in providing high-efficiency spray guns that enhance coating quality while reducing material waste. Their products are designed for various applications, including automotive, furniture, and industrial coatings.

Key Features

- High Transfer Efficiency: Ramseier's electrostatic spray guns are engineered to maximize paint transfer, ensuring that more paint adheres to the surface rather than being lost to overspray.

- Versatile Applications: These spray guns can be used for a wide range of materials, including water-based and solvent-based paints, making them suitable for diverse industries.

- User-Friendly Design: The ergonomic design of Ramseier's spray guns allows for comfortable handling, reducing operator fatigue during extended use.

2. Nordson Corporation

Overview

Nordson is a global leader in precision dispensing and coating technologies. Their electrostatic spray guns are known for their reliability and efficiency, making them a popular choice among manufacturers in Romania.

Key Features

- Advanced Technology: Nordson's electrostatic spray guns utilize cutting-edge technology to ensure consistent coating thickness and quality.

- High Voltage Systems: Their systems operate at high voltages, which enhances the electrostatic attraction of paint particles to the substrate, resulting in superior coverage.

- Robust Construction: Designed for durability, Nordson spray guns can withstand the rigors of industrial environments.

3. Graco Inc.

Overview

Graco is a well-established name in the spray equipment industry, offering a wide range of electrostatic spray guns that cater to various market needs.

Key Features

- Pro Xp Electrostatic Spray Guns: Graco's Pro Xp series is designed for high transfer efficiency and reduced overspray, making it ideal for high-production environments.

- Versatile Applications: These guns are suitable for both liquid and powder coatings, providing flexibility for manufacturers.

- Innovative Design: Graco focuses on ergonomic designs that enhance user comfort and control.

4. Binks

Overview

Binks has a long history of providing high-quality spray equipment, including electrostatic spray guns that are widely used in the coating industry.

Key Features

- Comprehensive Solutions: Binks offers a complete range of electrostatic spray guns, from manual to automated systems, catering to different production scales.

- Efficiency and Quality: Their guns are designed to deliver high-quality finishes while minimizing waste, making them a cost-effective choice for manufacturers.

- Customizable Options: Binks provides customizable solutions to meet specific customer needs, ensuring optimal performance in various applications.

5. Sames Kremlin

Overview

Sames Kremlin specializes in advanced coating technologies, including electrostatic spray guns that are designed for high efficiency and precision.

Key Features

- High Transfer Efficiency: Their electrostatic spray guns are engineered to achieve high transfer efficiency, reducing material waste and improving overall productivity.

- Robust Performance: Sames Kremlin's products are built to perform in demanding industrial environments, ensuring reliability and longevity.

- Innovative Technology: The company invests in research and development to continuously improve their spray gun technology, keeping pace with industry advancements.

Conclusion

The electrostatic spray gun market in Romania is thriving, with several manufacturers leading the way in innovation and efficiency. Companies like Ramseier Koatings Technologies Holdings Ltd., Nordson, Graco, Binks, and Sames Kremlin are at the forefront, providing high-quality solutions that meet the diverse needs of the coating industry. As the demand for efficient and environmentally friendly coating solutions continues to grow, these manufacturers are well-positioned to lead the charge.

Frequently Asked Questions (FAQs)

1. What is an electrostatic spray gun?

An electrostatic spray gun is a device that uses electrostatic charge to attract paint particles to a surface, resulting in a more efficient coating process with less overspray.

2. How does an electrostatic spray gun work?

Electrostatic spray guns apply a negative charge to the paint particles, which are then attracted to a grounded surface, ensuring even coverage and reducing waste.

3. What are the benefits of using electrostatic spray guns?

The benefits include high transfer efficiency, reduced material waste, improved finish quality, and lower environmental impact due to decreased volatile organic compounds (VOCs).

4. Can electrostatic spray guns be used for all types of coatings?

Yes, electrostatic spray guns can be used for various coatings, including water-based, solvent-based, and powder coatings, making them versatile for different applications.

5. How do I choose the right electrostatic spray gun for my needs?

Consider factors such as the type of coating, production volume, and specific application requirements. Consulting with manufacturers can also help in selecting the best option.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.