Content Menu

● Understanding Electrostatic Spray Guns

>> The Manufacturing Process of Electrostatic Spray Guns

>>> Design and Engineering

>>> Component Sourcing

>>> Assembly

>>> Testing

>> Market Trends in Kazakhstan

>>> Growing Demand for Eco-Friendly Solutions

>>> Expansion of the Manufacturing Sector

>>> Technological Advancements

>> Applications of Electrostatic Spray Guns

>>> Automotive Industry

>>> Furniture Coating

>>> Industrial Equipment

>> Leading Electrostatic Spray Gun Manufacturers in Kazakhstan

>> Frequently Asked Questions

>>> What are the benefits of using electrostatic spray guns?

>>> How do electrostatic spray guns work?

>>> What industries use electrostatic spray guns?

>>> Are electrostatic spray guns easy to maintain?

>>> What should I consider when choosing an electrostatic spray gun?

>> Conclusion

In the realm of industrial coating, electrostatic spray guns have emerged as a pivotal technology, enhancing efficiency and quality in various applications. This article delves into the leading manufacturers and suppliers of electrostatic spray guns in Kazakhstan, with a particular focus on Ramseier Koatings Technologies Holdings Ltd., a prominent player in the industry.

Understanding Electrostatic Spray Guns

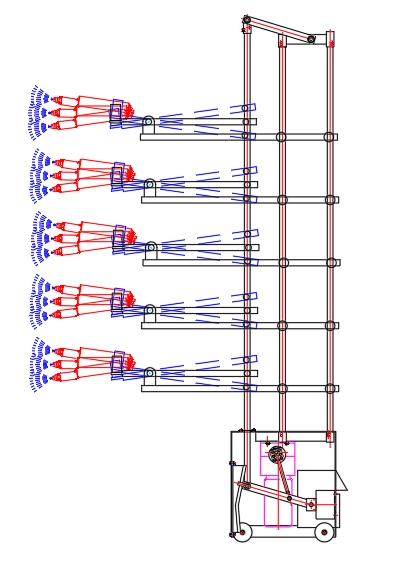

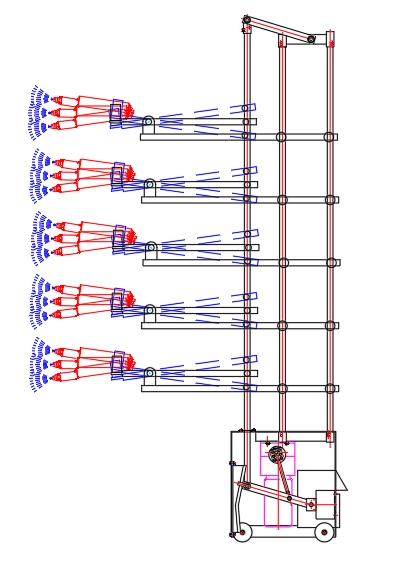

Electrostatic spray guns utilize an electric charge to attract paint particles to the surface being coated. This technology not only improves transfer efficiency but also minimizes overspray, making it an environmentally friendly option. The following sections will explore the manufacturing processes, market trends, and applications of these innovative tools.

The Manufacturing Process of Electrostatic Spray Guns

The production of electrostatic spray guns involves several critical steps:

Design and Engineering

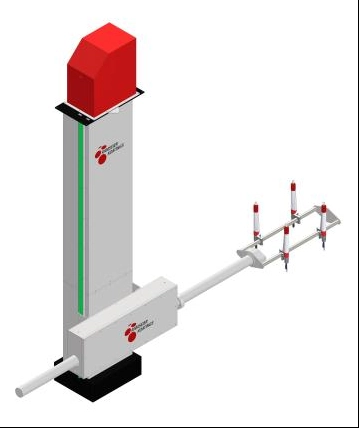

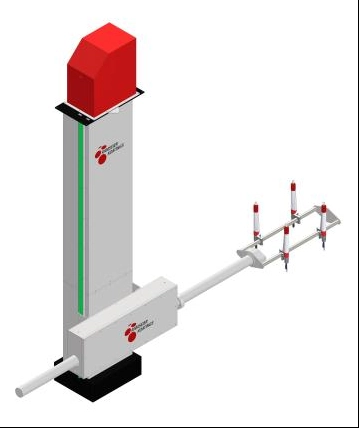

The design phase is crucial, as it determines the gun's efficiency and usability. Engineers focus on creating ergonomic designs that allow for ease of use while ensuring that the gun can handle various types of coatings.

Component Sourcing

High-quality components are essential for the performance of electrostatic spray guns. Manufacturers source materials that can withstand the rigors of industrial use, including durable plastics and metals that resist corrosion.

Assembly

During assembly, each component is meticulously put together. This process often involves automated systems to ensure precision and consistency. Quality control checks are implemented at various stages to maintain high standards.

Testing

Before reaching the market, each spray gun undergoes rigorous testing. This includes performance tests to ensure that the gun achieves the desired transfer efficiency and coating quality.

Market Trends in Kazakhstan

The market for electrostatic spray guns in Kazakhstan is influenced by several factors:

Growing Demand for Eco-Friendly Solutions

As industries become more environmentally conscious, the demand for electrostatic spray guns is increasing. These guns reduce paint waste and lower volatile organic compound (VOC) emissions, aligning with global sustainability goals.

Expansion of the Manufacturing Sector

Kazakhstan's manufacturing sector is expanding, leading to a higher demand for efficient coating solutions. Electrostatic spray guns are favored for their ability to provide a uniform finish while reducing operational costs.

Technological Advancements

Innovations in electrostatic spray technology are driving market growth. Manufacturers are continually improving their products, incorporating features such as digital controls and enhanced safety mechanisms.

Applications of Electrostatic Spray Guns

Electrostatic spray guns are versatile tools used across various industries:

Automotive Industry

In the automotive sector, electrostatic spray guns are used for painting vehicles, providing a smooth and durable finish. The ability to control the spray pattern and reduce overspray makes these guns ideal for high-volume production environments.

Furniture Coating

The furniture industry benefits from electrostatic spray guns, which allow for even coating of complex shapes and surfaces. This technology ensures that every piece receives a consistent finish, enhancing the overall quality of the product.

Industrial Equipment

Manufacturers of industrial equipment utilize electrostatic spray guns to apply protective coatings that enhance durability and resistance to corrosion. This application is crucial for equipment that operates in harsh environments.

Leading Electrostatic Spray Gun Manufacturers in Kazakhstan

1. Ramseier Koatings Technologies Holdings Ltd.

- Renowned for its high-quality electrostatic spray guns, Ramseier offers a range of products tailored to various industrial applications. Their commitment to innovation and quality has made them a leader in the market.

2. Wagner Group

- Wagner is a global leader in coating technology, providing advanced electrostatic spray solutions that cater to diverse industries. Their products are known for their reliability and efficiency.

3. Graco Inc.

- Graco specializes in fluid handling systems and offers a variety of electrostatic spray guns designed for high performance. Their products are widely used in automotive and industrial applications.

4. Binks

- Binks is recognized for its innovative spray technology, including electrostatic spray guns that deliver superior finish quality. Their products are designed for ease of use and maintenance.

5. Nordson Corporation

- Nordson provides a range of electrostatic spray solutions that enhance coating efficiency and quality. Their commitment to customer satisfaction and product innovation sets them apart in the industry.

Frequently Asked Questions

What are the benefits of using electrostatic spray guns?

Electrostatic spray guns offer several advantages, including improved transfer efficiency, reduced overspray, and a more uniform coating finish. They are also more environmentally friendly compared to traditional spray methods.

How do electrostatic spray guns work?

These guns work by charging the paint particles as they exit the nozzle. The charged particles are attracted to the grounded surface, ensuring that more paint adheres to the object being coated.

What industries use electrostatic spray guns?

Electrostatic spray guns are used in various industries, including automotive, furniture manufacturing, and industrial equipment production. Their versatility makes them suitable for any application requiring a high-quality finish.

Are electrostatic spray guns easy to maintain?

Yes, electrostatic spray guns are designed for easy maintenance. Regular cleaning and occasional part replacements are typically all that is needed to keep them in optimal working condition.

What should I consider when choosing an electrostatic spray gun?

When selecting an electrostatic spray gun, consider factors such as the type of coating, the size of the objects being painted, and the desired finish quality. It's also important to evaluate the manufacturer's reputation and support services.

Conclusion

Electrostatic spray guns are revolutionizing the coating industry in Kazakhstan, providing efficient, high-quality solutions for various applications. With leading manufacturers like Ramseier Koatings Technologies Holdings Ltd. at the forefront, the future of electrostatic spray technology looks promising. As industries continue to prioritize sustainability and efficiency, the demand for these innovative tools is expected to grow.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.