Content Menu

● Introduction

● What is an Automatic Electrostatic Spray Gun?

>> How Electrostatic Spray Guns Work

>> Advantages of Automatic Electrostatic Spray Guns

● Leading Manufacturers of Automatic Electrostatic Spray Guns

>> 1. Ramseier Koatings Technologies Holdings Ltd.

>> 2. Nordson Corporation

>> 3. Graco Inc.

>> 4. ANEST IWATA Corporation

>> 5. Weifang Galin Powder Coating Equipment Co., Ltd.

>> 6. Hangzhou Color Powder Coating Equipment Co., Ltd.

>> 7. GoldSpray S.L.

● Key Technologies and Innovations in Automatic Electrostatic Spray Guns

>> High Voltage Electrostatic Charging

>> Induction and Corona Charging Methods

>> Integration with Automation Systems

>> Material Compatibility and Versatility

● Applications of Automatic Electrostatic Spray Guns

>> Automotive Industry

>> Furniture and Woodworking

>> Aerospace and Electronics

>> Agricultural and Chemical Sectors

● Choosing the Right Automatic Electrostatic Spray Gun Manufacturer

● Frequently Asked Questions

● Conclusion

Introduction

In the world of industrial coating, electrostatic spray guns have become essential tools for achieving high-quality finishes with minimal waste. This article explores the top manufacturers and suppliers of automatic electrostatic spray guns in Romania, highlighting their innovations, product offerings, and contributions to the industry. Among these, Ramseier Koatings Technologies Holdings Ltd. stands out as a leader in providing advanced electrostatic spray solutions.

What is an Automatic Electrostatic Spray Gun?

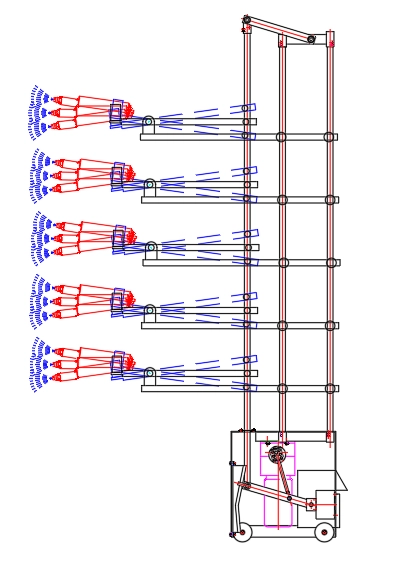

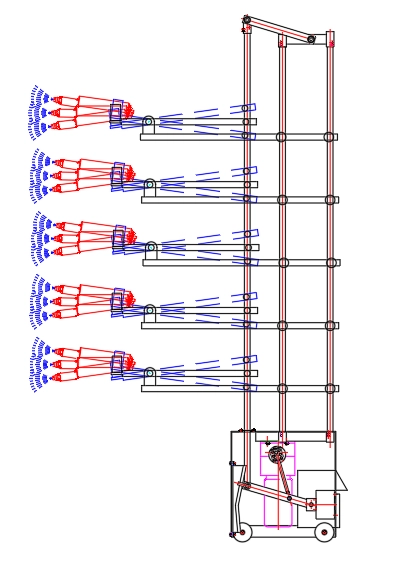

Automatic electrostatic spray guns utilize electrostatic principles to enhance the application of coatings. By charging paint particles as they exit the nozzle, these guns ensure that the particles are attracted to the grounded surface, resulting in improved transfer efficiency and reduced overspray. This technology is particularly beneficial in high-volume production environments where consistency and quality are paramount.

How Electrostatic Spray Guns Work

Electrostatic spray guns operate by imparting an electrical charge to the coating material. This charge causes the particles to be attracted to the surface being coated, which not only improves the efficiency of the coating process but also enhances the quality of the finish. The automatic versions of these guns are often integrated into robotic systems, allowing for precise and consistent application across various surfaces.

Advantages of Automatic Electrostatic Spray Guns

- High Transfer Efficiency: More coating material adheres to the target, reducing waste.

- Uniform Coverage: Electrostatic attraction ensures even coating on complex shapes.

- Material Savings: Less paint or powder is wasted, lowering operational costs.

- Environmental Benefits: Reduced overspray means less airborne pollutants.

- Increased Productivity: Automation allows continuous, fast application without fatigue.

Leading Manufacturers of Automatic Electrostatic Spray Guns

1. Ramseier Koatings Technologies Holdings Ltd.

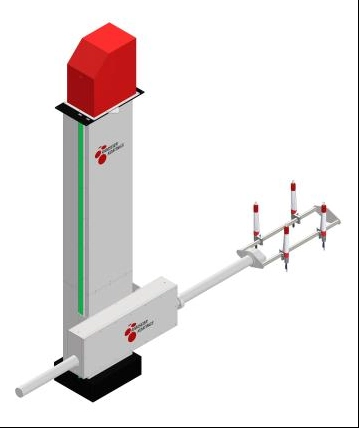

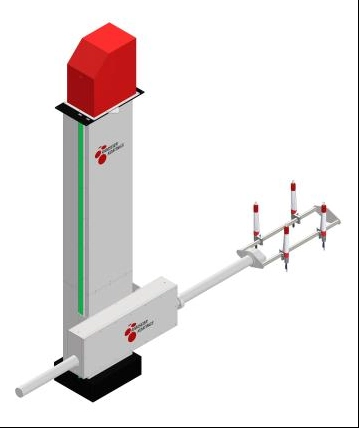

Ramseier Koatings is a prominent player in the electrostatic spray gun market, known for its innovative solutions and high-quality products. The company specializes in manufacturing automatic electrostatic spray guns that cater to various industries, including automotive, furniture, and electronics. Their products are designed to maximize efficiency and minimize waste, making them a preferred choice for manufacturers looking to enhance their coating processes.

2. Nordson Corporation

Nordson is a global leader in precision dispensing and coating equipment. Their Encore® series of automatic electrostatic spray guns are renowned for their reliability and performance. With capabilities of producing up to 100 kV of electrostatic charge, Nordson's guns ensure superior transfer efficiency and coating quality, making them ideal for automotive and appliance industries.

3. Graco Inc.

Graco is well-known for its extensive range of spray guns, including automatic electrostatic models. Their Pro Xp series offers high transfer efficiency and is designed for various applications, from industrial coatings to fine finishes. Graco's commitment to innovation ensures that their electrostatic spray guns meet the evolving needs of the market.

4. ANEST IWATA Corporation

Founded in 1926, ANEST IWATA is a pioneer in spray equipment technology. Their automatic electrostatic spray guns are designed for high efficiency and uniform coating, making them suitable for a wide range of applications, including automotive and woodworking. The company's focus on energy efficiency and quality has established it as a trusted name in the industry.

5. Weifang Galin Powder Coating Equipment Co., Ltd.

Weifang Galin specializes in powder coating equipment, including electrostatic spray guns. Their products are known for high powder charge rates and efficiency, making them suitable for various industrial applications. The company offers comprehensive service and customization options, catering to the specific needs of their clients.

6. Hangzhou Color Powder Coating Equipment Co., Ltd.

This company focuses on providing advanced powder coating solutions, including automatic electrostatic spray guns. Their products are designed to efficiently spray complex shapes and are exported worldwide, earning a reputation for reliability and innovation.

7. GoldSpray S.L.

Located in Spain, GoldSpray offers a range of coating equipment, including electrostatic spray guns. Their commitment to quality and service has made them a preferred supplier for various industries, including food and furniture.

Key Technologies and Innovations in Automatic Electrostatic Spray Guns

High Voltage Electrostatic Charging

Modern electrostatic spray guns utilize high-voltage power supplies to generate electrostatic charges, significantly improving the attraction of coating particles to the target surface. This technology reduces overspray and enhances coating uniformity.

Induction and Corona Charging Methods

Different manufacturers employ either induction or corona charging methods. Induction charging involves charging particles inside the spray gun without direct electrical contact, improving safety and atomization quality. Corona charging uses a high-voltage electrode to ionize air and charge particles, which is common in powder coating guns.

Integration with Automation Systems

Automatic electrostatic spray guns are often integrated with robotic arms and conveyor systems for precise, repeatable coating applications. Advanced control systems allow for fine-tuning of spray parameters such as voltage, flow rate, and spray pattern, optimizing performance for different materials and shapes.

Material Compatibility and Versatility

Leading manufacturers design their guns to handle a wide range of coating materials, including liquid paints, powders, and specialty coatings. This versatility allows their products to be used across industries from automotive to electronics and agriculture.

Applications of Automatic Electrostatic Spray Guns

Automotive Industry

Automatic electrostatic spray guns are extensively used for painting car bodies and parts, ensuring smooth, durable finishes with minimal paint waste. The technology supports high-volume production lines with consistent quality.

Furniture and Woodworking

Electrostatic spray guns provide even coatings on wood and furniture, including complex shapes and recesses, enhancing appearance and durability while reducing environmental impact.

Aerospace and Electronics

Precision coating is critical in aerospace and electronics manufacturing. Automatic electrostatic spray guns deliver uniform layers of protective and functional coatings, improving product performance and lifespan.

Agricultural and Chemical Sectors

These guns are also used for spraying pesticides, herbicides, and chemical coatings, ensuring thorough coverage and efficient use of materials.

Choosing the Right Automatic Electrostatic Spray Gun Manufacturer

When selecting a manufacturer, consider:

- Product range and specialization: Does the company offer guns suitable for your specific application?

- Technological innovation: Are their products equipped with the latest electrostatic charging and automation features?

- Service and support: Is there reliable after-sales service and customization options?

- Global presence: Can the manufacturer supply and support your operations worldwide?

- Reputation and experience: How long has the company been in the industry, and what is their track record?

Frequently Asked Questions

1. What industries benefit most from automatic electrostatic spray guns?

- Automotive, aerospace, furniture, electronics, and chemical industries utilize these guns for efficient, high-quality coating applications.

2. How do automatic electrostatic spray guns reduce paint waste?

- They charge paint particles electrically, attracting them to the target surface and minimizing overspray, which reduces material loss.

3. What is the difference between induction and corona charging in electrostatic spray guns?

- Induction charging charges particles inside the gun without direct contact, enhancing safety and atomization, while corona charging uses a high-voltage electrode to ionize air and charge particles externally.

4. Can automatic electrostatic spray guns handle both liquid and powder coatings?

- Yes, manufacturers offer models designed for liquid paints and powder coatings, often with specific features optimized for each type.

5. How important is after-sales service when choosing a spray gun manufacturer?

- Very important. Reliable service ensures maintenance, spare parts availability, and technical support, which are critical for continuous production.

Conclusion

The landscape of automatic electrostatic spray guns in Romania is vibrant, with several manufacturers leading the charge in innovation and quality. Ramseier Koatings Technologies Holdings Ltd. is at the forefront, providing advanced solutions that cater to the diverse needs of various industries. As the demand for efficient and high-quality coating solutions continues to grow, these manufacturers are well-positioned to meet the challenges of the future.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.