Content Menu

● Introduction

● Understanding Powder Coating

>> What is Powder Coating?

>> Advantages of Powder Coating

● The Mechanism of Electrostatic Spray Guns

>> How Electrostatic Spray Guns Work

>> Components of Electrostatic Spray Guns

● Benefits of Using Electrostatic Spray Guns in Automated Systems

>> Enhanced Transfer Efficiency

>> Improved Coating Quality

>> Increased Production Speed

>> Versatility in Application

● The Role of Automation in Powder Coating

>> Integration of Automation in Powder Coating Systems

>> Types of Automated Powder Coating Systems

● Challenges and Solutions in Using Electrostatic Spray Guns

>> Common Challenges

>> Solutions to Overcome Challenges

● Future Trends in Electrostatic Spray Guns and Powder Coating

>> Technological Advancements

>> Sustainability Focus

>> Customization and Flexibility

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of using electrostatic spray guns in powder coating?

>> 2. How do electrostatic spray guns improve coating quality?

>> 3. What types of materials can be coated using electrostatic spray guns?

>> 4. What are some common challenges associated with electrostatic spray guns?

>> 5. How can manufacturers overcome the challenges of using electrostatic spray guns?

Introduction

In the realm of industrial finishing, powder coating has emerged as a preferred method for applying a durable and aesthetically pleasing finish to a variety of substrates. Among the technologies that have revolutionized this process, electrostatic spray guns stand out for their efficiency and effectiveness. This article delves into the role of electrostatic spray guns in automated powder coating systems, exploring their functionality, advantages, and the future of this technology in manufacturing.

Understanding Powder Coating

What is Powder Coating?

Powder coating is a dry finishing process that uses finely ground particles of pigment and resin, which are electrostatically charged and sprayed onto a surface. The coated object is then heated in an oven, causing the powder to melt and form a smooth, durable finish. This method is widely used in various industries, including automotive, furniture, and appliances, due to its superior finish and environmental benefits.

Advantages of Powder Coating

The advantages of powder coating over traditional liquid coatings are numerous. These include:

- Durability: Powder coatings are more resistant to chipping, scratching, and fading.

- Environmental Benefits: Powder coating produces minimal volatile organic compounds (VOCs), making it a more environmentally friendly option.

- Cost-Effectiveness: The process is generally more economical due to reduced material waste and lower energy consumption.

The Mechanism of Electrostatic Spray Guns

How Electrostatic Spray Guns Work

Electrostatic spray guns operate by charging the powder particles as they are sprayed from the gun. This charge causes the particles to be attracted to the grounded surface of the object being coated. The result is a more uniform application, with less overspray and waste.

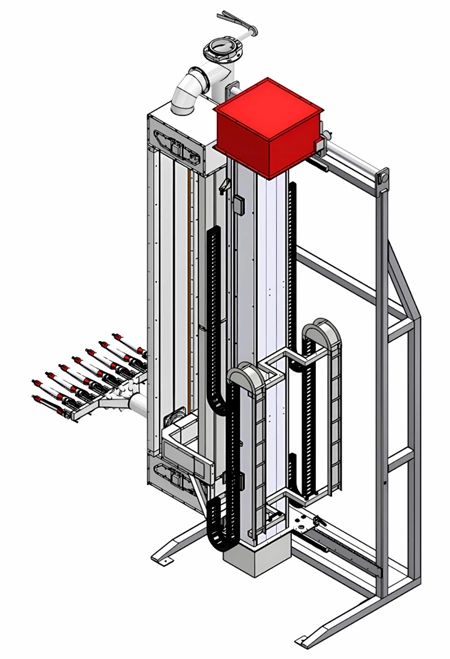

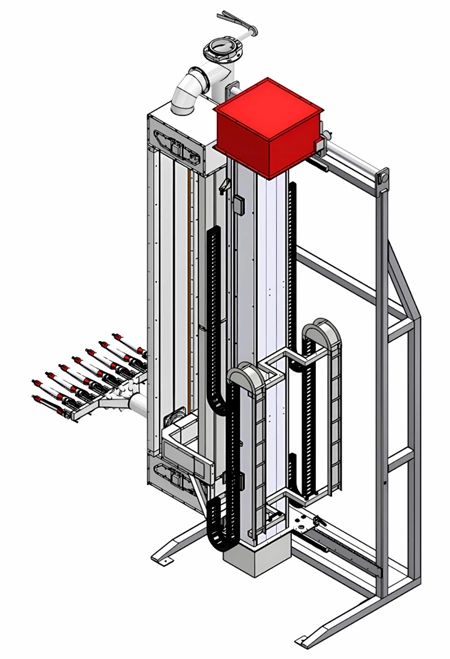

Components of Electrostatic Spray Guns

Electrostatic spray guns consist of several key components:

- Gun Body: The main structure that houses the internal components.

- Electrode: A charged component that imparts an electrostatic charge to the powder particles.

- Air Cap: This component atomizes the powder and directs it towards the substrate.

- Control Unit: Regulates the voltage and air pressure, allowing for precise control over the spray pattern and thickness.

Benefits of Using Electrostatic Spray Guns in Automated Systems

Enhanced Transfer Efficiency

One of the primary benefits of electrostatic spray guns is their high transfer efficiency. This means that a greater percentage of the powder reaches the surface of the object being coated, reducing waste and improving cost-effectiveness. In automated systems, this efficiency is crucial for maintaining consistent quality and reducing material costs.

Improved Coating Quality

Electrostatic spray guns provide a superior finish compared to traditional spray methods. The electrostatic charge helps the powder particles to wrap around complex shapes and edges, ensuring even coverage. This is particularly important in automated systems where precision is key.

Increased Production Speed

Automated powder coating systems equipped with electrostatic spray guns can significantly increase production speed. The ability to quickly and efficiently coat large volumes of products without compromising quality allows manufacturers to meet high demand while maintaining profitability.

Versatility in Application

Electrostatic spray guns are versatile and can be used to coat a wide range of materials, including metals, plastics, and wood. This adaptability makes them suitable for various industries, from automotive to furniture manufacturing.

The Role of Automation in Powder Coating

Integration of Automation in Powder Coating Systems

The integration of automation in powder coating systems has transformed the industry. Automated systems can operate continuously, reducing labor costs and minimizing human error. This is particularly beneficial in high-volume production environments where consistency and speed are essential.

Types of Automated Powder Coating Systems

There are several types of automated powder coating systems, including:

- Robotic Systems: These systems use robotic arms equipped with electrostatic spray guns to coat products with precision.

- Conveyor Systems: Products are moved through a coating booth on a conveyor, allowing for continuous operation and efficient coating.

- Batch Systems: These systems are designed for smaller production runs and can be easily adjusted for different products.

Challenges and Solutions in Using Electrostatic Spray Guns

Common Challenges

While electrostatic spray guns offer numerous benefits, there are challenges associated with their use:

- Static Electricity Issues: Excessive static can lead to powder clumping or uneven application.

- Maintenance Requirements: Regular maintenance is necessary to ensure optimal performance and longevity of the equipment.

- Training Needs: Operators must be trained to use the equipment effectively and safely.

Solutions to Overcome Challenges

To address these challenges, manufacturers can implement several strategies:

- Regular Maintenance: Establishing a routine maintenance schedule can help prevent issues related to static electricity and equipment wear.

- Operator Training: Providing comprehensive training for operators can enhance their understanding of the equipment and improve overall efficiency.

- Investing in Technology: Upgrading to advanced electrostatic spray guns with built-in features to mitigate static issues can enhance performance.

Future Trends in Electrostatic Spray Guns and Powder Coating

Technological Advancements

The future of electrostatic spray guns in powder coating systems looks promising, with ongoing advancements in technology. Innovations such as improved charging mechanisms, enhanced control systems, and smart technology integration are expected to further enhance the efficiency and effectiveness of these systems.

Sustainability Focus

As industries continue to prioritize sustainability, the demand for eco-friendly coating solutions will grow. Electrostatic spray guns, with their low VOC emissions and reduced waste, are well-positioned to meet this demand. Manufacturers are likely to invest in research and development to create even more sustainable powder coating solutions.

Customization and Flexibility

The trend towards customization in manufacturing will also influence the development of electrostatic spray guns. Future systems may offer greater flexibility in terms of powder types, colors, and application techniques, allowing manufacturers to cater to specific customer needs.

Conclusion

Electrostatic spray guns play a crucial role in the efficiency and effectiveness of automated powder coating systems. Their ability to enhance transfer efficiency, improve coating quality, and increase production speed makes them an invaluable asset in modern manufacturing. As technology continues to advance, the future of electrostatic spray guns looks bright, with opportunities for further innovation and sustainability.

Frequently Asked Questions

1. What is the main advantage of using electrostatic spray guns in powder coating?

The main advantage is their high transfer efficiency, which reduces waste and ensures a more uniform application of powder.

2. How do electrostatic spray guns improve coating quality?

They impart an electrostatic charge to the powder particles, allowing them to wrap around complex shapes and edges for even coverage.

3. What types of materials can be coated using electrostatic spray guns?

Electrostatic spray guns can coat a variety of materials, including metals, plastics, and wood.

4. What are some common challenges associated with electrostatic spray guns?

Common challenges include static electricity issues, maintenance requirements, and the need for operator training.

5. How can manufacturers overcome the challenges of using electrostatic spray guns?

Manufacturers can implement regular maintenance schedules, provide comprehensive operator training, and invest in advanced technology to mitigate issues.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.