Content Menu

● Understanding Powder Coating and Spray Gun Basics

>> What Is Powder Coating?

>> Role of the Spray Gun Unit in Powder Coating

● Recent Innovations in Spray Gun Unit Design

>> Enhanced Electrostatic Charging Systems

>> Smart Sensor Integration

>> Modular and Lightweight Designs

● Benefits of Advanced Spray Gun Units

>> Improved Transfer Efficiency

>> Superior Coating Quality and Consistency

>> Enhanced Environmental Sustainability

● Emerging Technologies Shaping Spray Gun Evolution

>> AI and Machine Learning Integration

>> Wireless and IoT Connectivity

>> Advanced Material Compatibility

● Challenges and Considerations for Adoption

>> Initial Cost and Training

>> Maintenance Complexity

>> Compatibility with Existing Systems

● Future Outlook and Industry Impact

>> Increased Automation

>> Customization for Niche Applications

>> Environmental Regulatory Compliance

● Conclusion

● Frequently Asked Questions (FAQs)

Powder coating has long been a preferred finishing process for many industries, offering durable, high-quality, and environmentally friendly coatings. Advances in technology continue to enhance this process, and one of the most critical components driving this evolution is the spray gun unit. As companies demand greater efficiency, precision, and sustainability, innovations in spray gun design are reshaping the landscape of powder coating. This article explores the future of powder coating through the lens of spray gun unit developments, highlighting key advancements, benefits, and industry implications.

Understanding Powder Coating and Spray Gun Basics

What Is Powder Coating?

Powder coating is a dry finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto a grounded metal surface. The coated object is then cured under heat, allowing the powder to melt and form a smooth, hard finish. It is widely used across automotive, appliance, architectural, and industrial metal products due to its excellent resistance to corrosion, wear, and chemicals.

Role of the Spray Gun Unit in Powder Coating

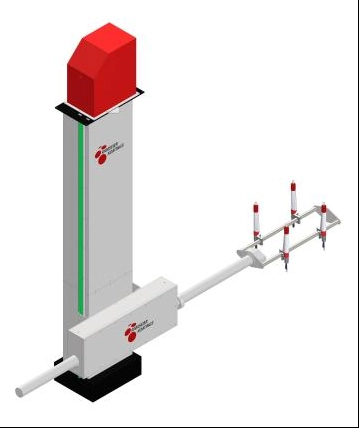

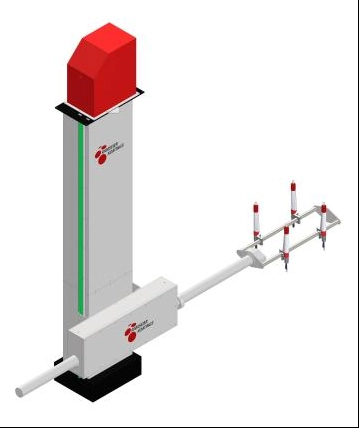

The spray gun is the device that applies electrostatically charged powder onto the surface of the workpiece. It plays a vital role in determining coating efficiency, quality, and transfer efficiency, which impacts material waste and environmental footprint. Traditional spray guns have remained relatively unchanged for decades, but new technological trends are accelerating innovation in their design.

Recent Innovations in Spray Gun Unit Design

Enhanced Electrostatic Charging Systems

One of the essential improvements has come in the electrostatic charging technology within spray guns. Traditional corona charging systems are being replaced or enhanced with tribo charging and improved high-voltage power supplies that deliver more consistent, stable charges. This results in better powder adhesion and more uniform coatings.

Smart Sensor Integration

Modern spray guns are increasingly equipped with integrated sensors that monitor parameters such as powder flow rate, charge level, distance to the object, and environmental factors. These sensors feed data in real-time to control systems, allowing for adjustable spray patterns and instant feedback to operators, boosting precision and reducing defects.

Modular and Lightweight Designs

Spray guns are becoming modular, allowing users to quickly swap components such as nozzles, electrodes, and powder delivery units. This modularity makes maintenance easier and adapts the gun for different applications. Additionally, the use of lightweight composite materials reduces operator fatigue during long production runs, improving ergonomics and productivity.

Benefits of Advanced Spray Gun Units

Improved Transfer Efficiency

Innovative gun designs are significantly enhancing transfer efficiency—meaning more powder reaches the target surface rather than being lost to overspray. Improved charging methods combined with optimized spray patterns reduce waste and lower material usage costs.

Superior Coating Quality and Consistency

Integrated sensors and adaptive control mechanics make it possible to maintain highly consistent coatings, even on complex shapes or varying substrate materials. This reduces rework and improves overall product quality.

Enhanced Environmental Sustainability

Reduced powder waste not only saves costs but also lessens environmental impact. Some modern spray guns incorporate advanced powder recovery systems and smart controls to minimize airborne powder dispersion and reduce emissions.

Emerging Technologies Shaping Spray Gun Evolution

AI and Machine Learning Integration

Artificial Intelligence (AI) is beginning to be applied to powder coating spray systems. Machine learning algorithms can analyze spray data and environmental conditions, optimizing powder usage and adjusting parameters dynamically for the best finish. This technology promises continuous improvement and predictive maintenance.

Wireless and IoT Connectivity

Wireless connectivity and Internet of Things (IoT) capabilities enable spray guns to communicate with factory automation systems. This connectivity facilitates remote monitoring, diagnostics, and automated reporting, making production smarter and more efficient.

Advanced Material Compatibility

New spray guns are being developed to handle a wider range of specialized powders, including ultra-fine or multi-component formulas. This broadens the application of powder coating to markets that demand precise, technical finishes.

Challenges and Considerations for Adoption

Initial Cost and Training

While advanced spray guns offer many benefits, their initial cost can be higher than traditional models. Companies need to balance investment against expected efficiency gains. Moreover, staff training on new technologies and system integration is critical for successful adoption.

Maintenance Complexity

More sophisticated guns with sensors and modular parts may require more maintenance expertise and spare parts inventory. Ensuring reliable operation over time demands appropriate support infrastructure.

Compatibility with Existing Systems

Incorporating innovative spray guns into legacy powder coating lines may require system modifications. Compatibility with existing powder supply, cure ovens, and control systems must be evaluated carefully.

Future Outlook and Industry Impact

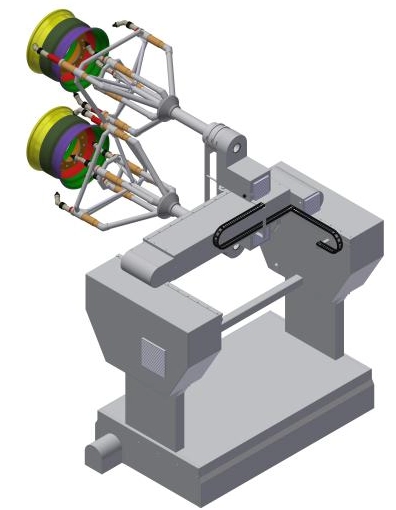

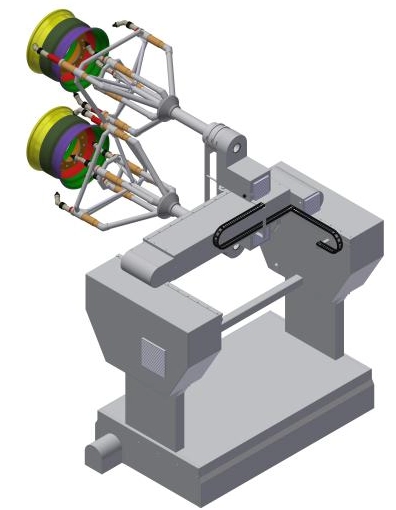

Increased Automation

Spray gun innovations are essential enablers of greater automation in powder coating. Combined with robotic arms and conveyors, next-generation spray guns support faster production speeds and higher throughput in sectors like automotive manufacturing.

Customization for Niche Applications

The flexibility offered by modular designs and adaptive controls means powder coating can be tailored to niche and high-performance markets such as aerospace, electronics, and medical devices, where coatings meet strict technical standards.

Environmental Regulatory Compliance

With growing environmental regulations worldwide, innovations that reduce powder consumption and airborne emissions help manufacturers meet more stringent requirements, avoiding regulatory penalties and improving corporate social responsibility.

Conclusion

The future of powder coating lies in the innovation of spray gun units, driving improvements in efficiency, quality, and sustainability. Electrostatic advancements, smart sensors, AI integration, and connectivity are transforming how coatings are applied, enabling manufacturers to meet evolving market demands and regulatory challenges. Companies that invest in these cutting-edge spray gun technologies will benefit from reduced costs, enhanced product quality, and a smaller environmental footprint, securing a competitive advantage in an increasingly sophisticated marketplace.

Frequently Asked Questions (FAQs)

Q1: How does electrostatic charging affect powder coating quality?

A1: Electrostatic charging helps powder particles adhere uniformly to the grounded substrate by creating an opposite charge attraction. Improved charging methods enhance particle distribution and reduce defects.

Q2: What are the advantages of modular spray gun designs?

A2: Modular designs facilitate easier maintenance, flexible adaptation to different coating needs, quicker part replacement, and reduce downtime, thus increasing productivity.

Q3: How do sensors improve powder coating spray guns?

A3: Sensors monitor spray parameters in real time, enabling automatic adjustments to powder flow and charge, resulting in better coating consistency and less overspray.

Q4: Can AI really optimize the powder coating process?

A4: Yes, AI analyzes complex spray data and environmental variables to continuously fine-tune spray parameters, improving coating uniformity and reducing waste.

Q5: What environmental benefits come from new spray gun technologies?

A5: Innovations reduce the amount of powder wasted through overspray and airborne dispersion, lowering emissions and material consumption, benefiting sustainability efforts.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.