Content Menu

● Introduction to Electrostatic Spray Guns

● Historical Context

>> Early Developments

>> The Rise of Manual Electrostatic Spray Guns

● Technological Innovations

>> Improved Charging Mechanisms

>> Enhanced Ergonomics

>> Integration of Smart Technology

● Environmental Considerations

>> Reduced VOC Emissions

>> Sustainability in Manufacturing

● Industry Applications

>> Automotive Industry

>> Furniture and Woodworking

>> Metal Fabrication

● Challenges and Future Directions

>> Initial Costs

>> Training and Skill Development

>> Future Innovations

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using manual electrostatic spray guns?

>> 2. How do electrostatic spray guns work?

>> 3. Are manual electrostatic spray guns suitable for all types of coatings?

>> 4. What maintenance is required for electrostatic spray guns?

>> 5. Can I use an electrostatic spray gun for outdoor applications?

The manual electrostatic spray gun has undergone significant advancements over the past decade, transforming the way industries apply coatings and finishes. This article explores the evolution of these tools, examining technological innovations, changes in design, and their impact on various sectors.

Introduction to Electrostatic Spray Guns

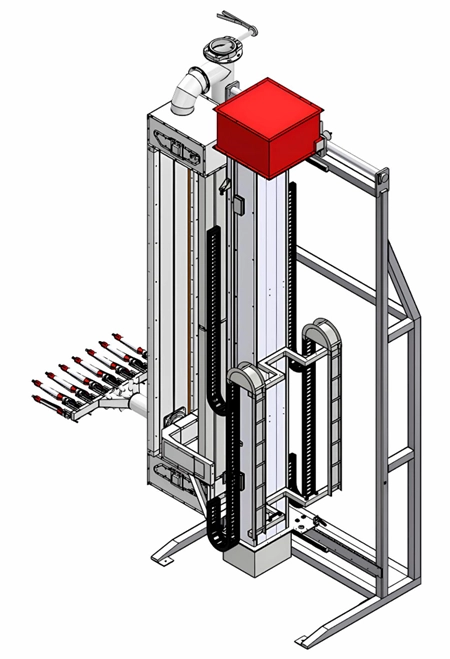

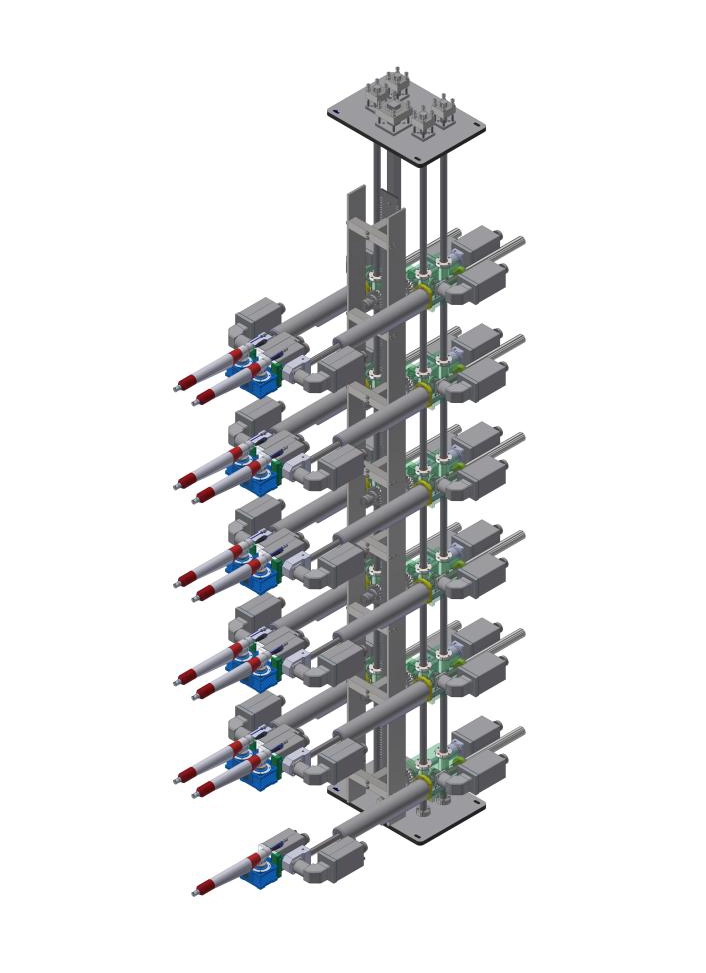

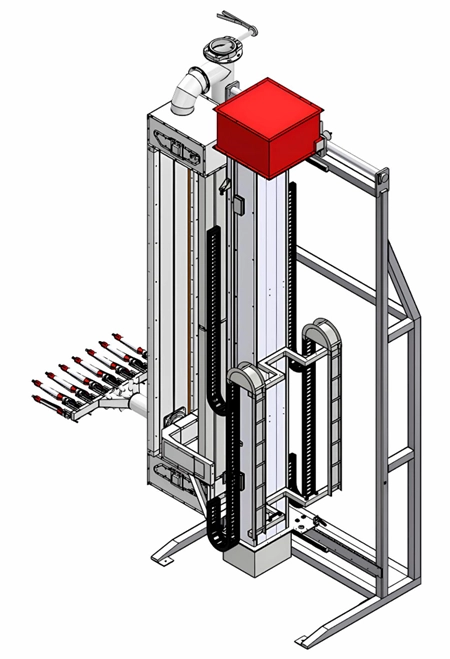

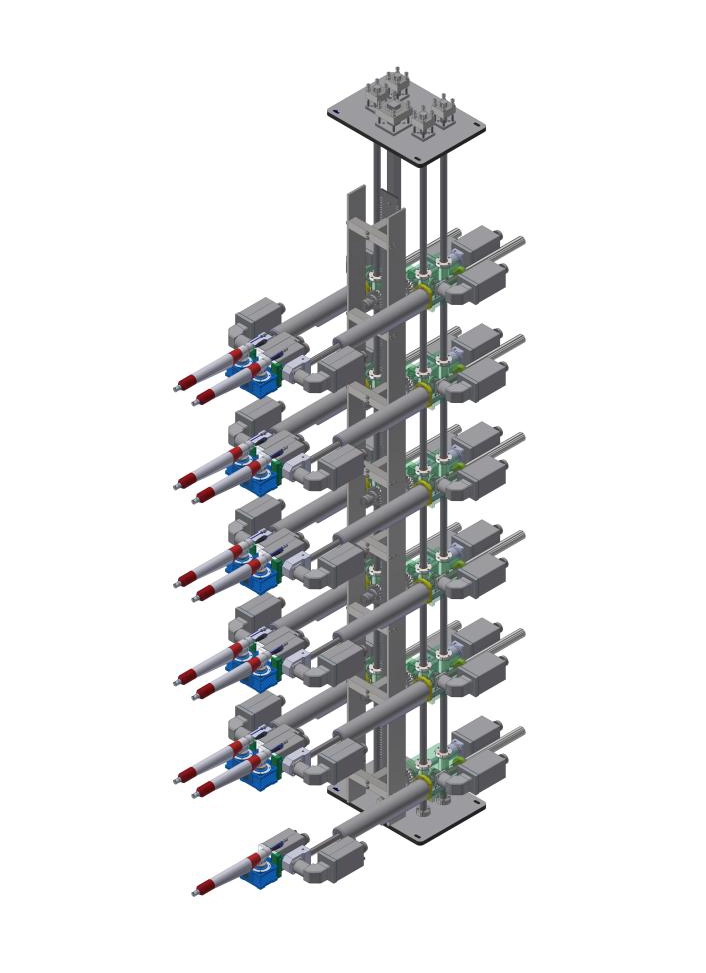

Electrostatic spray guns utilize an electric charge to enhance the application of paint and coatings. This technology allows for a more efficient transfer of paint to the surface, reducing overspray and waste. The principle behind electrostatic spraying is simple: the paint particles are charged as they exit the gun, and they are attracted to the oppositely charged surface, ensuring a uniform coating.

Historical Context

Early Developments

The concept of electrostatic spraying dates back to the 1930s, but it wasn't until the late 20th century that manual electrostatic spray guns became widely used in industrial applications. Initially, these guns were bulky and required significant maintenance. The early models were primarily used in automotive painting, where precision and efficiency were paramount.

The Rise of Manual Electrostatic Spray Guns

By the early 2010s, manual electrostatic spray guns began to gain popularity in various industries beyond automotive, including furniture, appliances, and metal fabrication. The need for more efficient and environmentally friendly coating processes drove the demand for these tools. Manufacturers started to innovate, focusing on improving the user experience and the performance of the guns.

Technological Innovations

Improved Charging Mechanisms

One of the most significant advancements in manual electrostatic spray guns has been the development of more efficient charging mechanisms. Modern guns utilize advanced electronics to provide a consistent and adjustable charge to the paint particles. This innovation allows for better control over the application process, resulting in a smoother finish and reduced material waste.

Enhanced Ergonomics

Ergonomics has become a critical focus in the design of manual electrostatic spray guns. Manufacturers have recognized that user comfort directly impacts productivity and quality. Newer models feature lightweight materials, improved grip designs, and adjustable settings that allow operators to customize the gun to their preferences. This focus on ergonomics has made it easier for users to handle the guns for extended periods without fatigue.

Integration of Smart Technology

The integration of smart technology into manual electrostatic spray guns is another notable trend. Some modern guns are equipped with sensors that monitor the application process in real-time. These sensors can provide feedback on the thickness of the coating, the amount of overspray, and even the environmental conditions. This data allows operators to make immediate adjustments, ensuring optimal performance and quality.

Environmental Considerations

Reduced VOC Emissions

As environmental regulations have tightened, the coatings industry has been under pressure to reduce volatile organic compound (VOC) emissions. Manual electrostatic spray guns have played a crucial role in this transition. The electrostatic process inherently reduces overspray, which means less paint is wasted and fewer VOCs are released into the atmosphere. Many manufacturers have developed low-VOC and water-based coatings specifically designed for use with electrostatic spray guns.

Sustainability in Manufacturing

The push for sustainability has also influenced the design and production of manual electrostatic spray guns. Manufacturers are increasingly using recyclable materials and sustainable practices in their production processes. This shift not only helps reduce the environmental impact of the guns themselves but also aligns with the broader goals of many companies to adopt greener practices.

Industry Applications

Automotive Industry

The automotive industry has been one of the primary beneficiaries of advancements in manual electrostatic spray guns. The need for high-quality finishes and efficient application processes has driven manufacturers to adopt these tools. Modern electrostatic spray guns allow for precise application, reducing the risk of defects and ensuring a consistent finish across vehicles.

Furniture and Woodworking

In the furniture and woodworking industries, manual electrostatic spray guns have revolutionized the way finishes are applied. The ability to achieve a smooth, even coat with minimal overspray has made these guns a preferred choice for manufacturers. Additionally, the reduced drying time associated with electrostatic spraying allows for faster production cycles.

Metal Fabrication

Metal fabrication is another sector that has embraced manual electrostatic spray guns. The durability and adhesion of coatings applied with these guns are particularly advantageous for metal surfaces. The electrostatic process ensures that even hard-to-reach areas receive an even coat, enhancing the overall quality of the finished product.

Challenges and Future Directions

Initial Costs

Despite their advantages, manual electrostatic spray guns can be more expensive than traditional spray guns. The initial investment may deter some smaller businesses from adopting this technology. However, the long-term savings associated with reduced material waste and improved efficiency often justify the cost.

Training and Skill Development

As with any advanced technology, proper training is essential for maximizing the benefits of manual electrostatic spray guns. Operators must understand how to adjust settings, maintain the equipment, and troubleshoot common issues. Manufacturers are increasingly offering training programs and resources to help users become proficient with these tools.

Future Innovations

Looking ahead, the future of manual electrostatic spray guns appears promising. Continued advancements in battery technology may lead to the development of cordless models, providing even greater flexibility and ease of use. Additionally, as smart technology continues to evolve, we can expect to see more features that enhance the user experience and improve application quality.

Conclusion

The evolution of manual electrostatic spray guns over the past decade has been marked by significant technological advancements, improved ergonomics, and a focus on environmental sustainability. As industries continue to seek more efficient and effective coating solutions, these tools will play a crucial role in shaping the future of surface finishing.

Frequently Asked Questions

1. What are the main advantages of using manual electrostatic spray guns?

Manual electrostatic spray guns offer several advantages, including reduced overspray, improved transfer efficiency, and a more uniform finish. They also contribute to lower VOC emissions, making them more environmentally friendly.

2. How do electrostatic spray guns work?

Electrostatic spray guns charge paint particles as they exit the nozzle. The charged particles are attracted to the oppositely charged surface, ensuring a more efficient application and reducing waste.

3. Are manual electrostatic spray guns suitable for all types of coatings?

While manual electrostatic spray guns are versatile, they are best suited for specific types of coatings, such as water-based and low-VOC paints. It's essential to check compatibility with the specific coating being used.

4. What maintenance is required for electrostatic spray guns?

Regular maintenance includes cleaning the gun after each use, checking for clogs, and ensuring that the charging mechanism is functioning correctly. Following the manufacturer's guidelines for maintenance is crucial for optimal performance.

5. Can I use an electrostatic spray gun for outdoor applications?

Yes, electrostatic spray guns can be used for outdoor applications, but it's essential to consider environmental factors such as wind and humidity, which can affect the application process.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.